Enhanced toughening recycled polyethylene material and preparation method thereof

A technology of strengthening and toughening polyethylene, which is applied in the field of preparation of reinforced and toughened recycled polyethylene materials, can solve the problems of excessive cross-linking, poor processing stability, and it is difficult to mix the cross-linking assistant and the matrix resin evenly, and the processing Good stability, improved tensile strength and impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

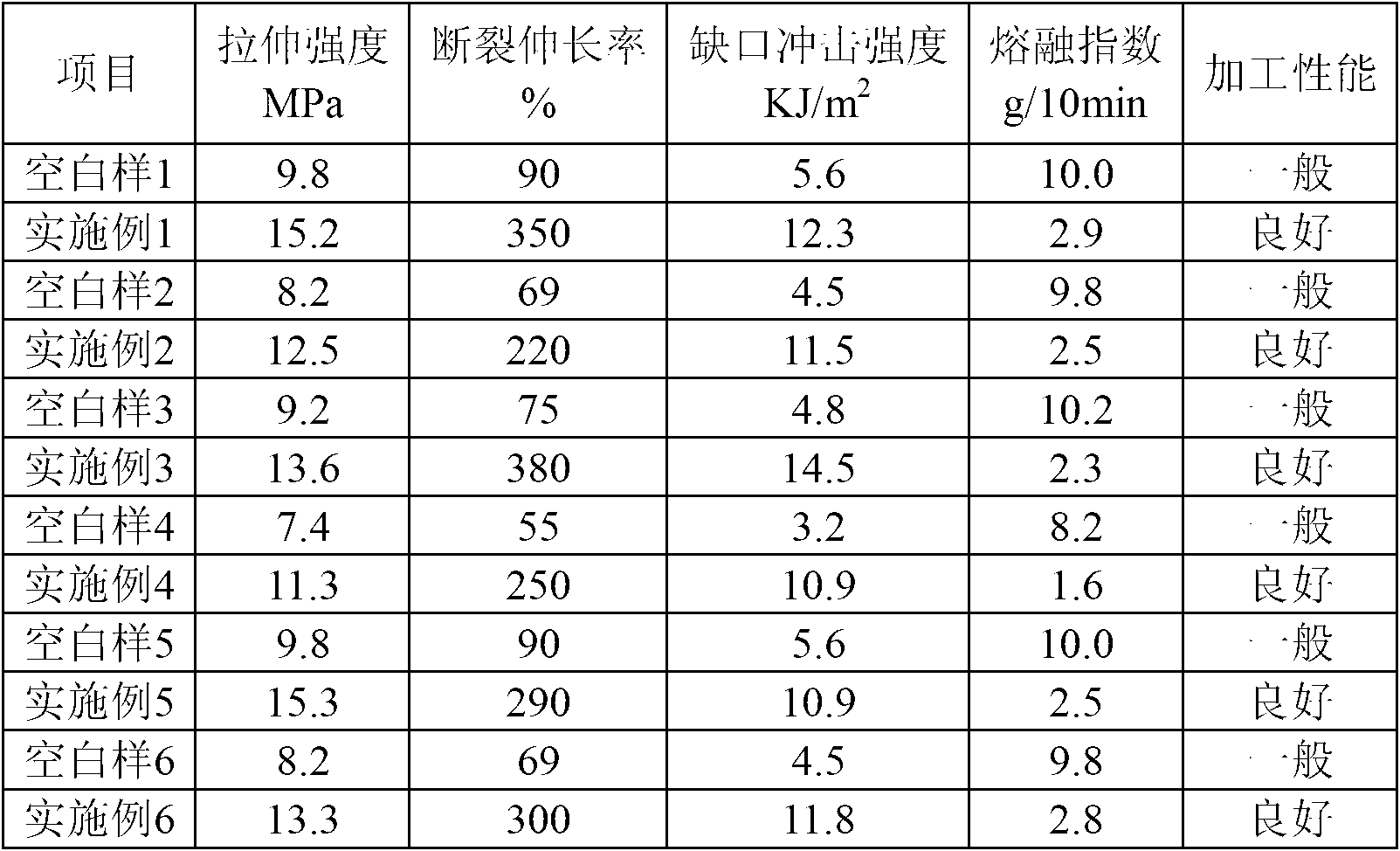

Embodiment 1

[0028] A reinforced and toughened recycled polyethylene material according to the present invention, which is made of the following raw materials in parts by mass: 100 parts of recycled polyethylene; 5 parts of cross-linked masterbatch; 0.5 part of antioxidant; 0.1 part of processing aid share.

[0029] The polyethylene recycled material is obtained from garbage plastics purchased from the market through classification compounding, melt blending and granulation, with a filler mass fraction of 20% and a density of 1.085g / cm 3 .

[0030] The cross-linked masterbatch is self-made, DBPH / TAIC / EVA colloidal particles.

[0031] In the above cross-linked masterbatch, the mass fraction of EVA is 96%, the mass fraction of DBPH is 3%, and the mass fraction of TAIC is 1%.

[0032] The antioxidant is a mixture of antioxidant 1010 and antioxidant 168, the ratio (mass ratio) of which is 3 / 1, and the processing aid is liquid paraffin.

[0033] Manufacturing process:

[0034] Preparation o...

Embodiment 2

[0038] A reinforced and toughened recycled polyethylene material according to the present invention, which is made of the following raw materials in parts by mass: 100 parts of recycled polyethylene; 3 parts of cross-linked masterbatch; 3 parts of toughening agent; 0.6 parts of agent; 0.2 parts of processing aid.

[0039] The polyethylene reclaimed material is obtained from garbage plastics purchased from the market through classification compounding, melt blending and granulation, with a filler mass fraction of 30% and a density of 1.118g / cm 3 .

[0040] The cross-linked masterbatch is self-made, DBPH / EGDMA / EVA colloidal particles.

[0041] In the above cross-linked masterbatch, the mass fraction of EVA is 97%, the mass fraction of DBPH is 2.5%, and the mass fraction of EGDMA is 0.5%.

[0042] The toughening agent is EPDM (Japan Mitsui 4045M), the antioxidant is a mixture of antioxidant 1010 and antioxidant 168, the ratio (mass ratio) is 3 / 1, and the processing aid is liqui...

Embodiment 3

[0046] A kind of reinforced and toughened recycled polyethylene material according to the present invention, which is made of the following raw materials in parts by mass: 100 parts of recycled polyethylene; 4 parts of cross-linked masterbatch; 2 parts of toughening agent; 0.8 parts of agent; 0.3 parts of processing aid.

[0047] The polyethylene recycled material is obtained from garbage plastics purchased from the market through classification compounding, melt blending and granulation, with a filler mass fraction of 25% and a density of 1.103g / cm 3 .

[0048] The cross-linked masterbatch is self-made, DBPH / EVA / EGDMA colloidal particles.

[0049] In the above cross-linked masterbatch, the mass fraction of EVA is 95%, the mass fraction of DBPH is 4%, and the mass fraction of EGDMA is 1%.

[0050] The toughening agent is POE (Japan Mitsui DF840), the antioxidant is a mixture of antioxidant 1010 and antioxidant 168, the ratio (mass ratio) is 3 / 1, and the processing aid is ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com