Rubber packing ring and manufacturing technology thereof

A technology of rubber sealing ring and synthetic rubber, which is applied in the connection of packing seal with fluid pressure, mechanical equipment, pipes/pipe joints/fittings, etc., which can solve the problems of unsatisfactory service life and safety, and achieve good sealing performance , low compression set, high elongation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The proportioning of the rubber sealing ring by weight is:

[0046] EPDM: 80 Carbon Black: 55

[0047] Paraffin oil: 15 Indirect zinc oxide: 4

[0048] Stearic acid: 0.2 Anti-aging agent: 2

[0049] Sulfur S-80: 0.1 Vulcanizing agent DCP: 3

[0050] Lubricant: 1

Embodiment 2

[0052] The proportioning of the rubber sealing ring by weight is:

[0053] EPDM: 100 Carbon Black: 65

[0054] Paraffin oil: 20 Indirect zinc oxide: 5

[0055] Stearic acid: 0.5 Anti-aging agent: 3

[0056] Sulfur S-80: 0.25 Vulcanizing agent DCP: 4

[0057] Lubricant: 2

Embodiment 3

[0059] The proportioning of the rubber sealing ring by weight is:

[0060] EPDM: 120 Carbon Black: 75

[0061] Paraffin oil: 25 Indirect zinc oxide: 6

[0062] Stearic acid: 1 Anti-aging agent: 4

[0063] Sulfur S-80: 0.35 Vulcanizing agent DCP: 5

[0064] Lubricant: 3

[0065] The lubricants in the above-mentioned embodiments 1-3 are preferably oleic acid amides.

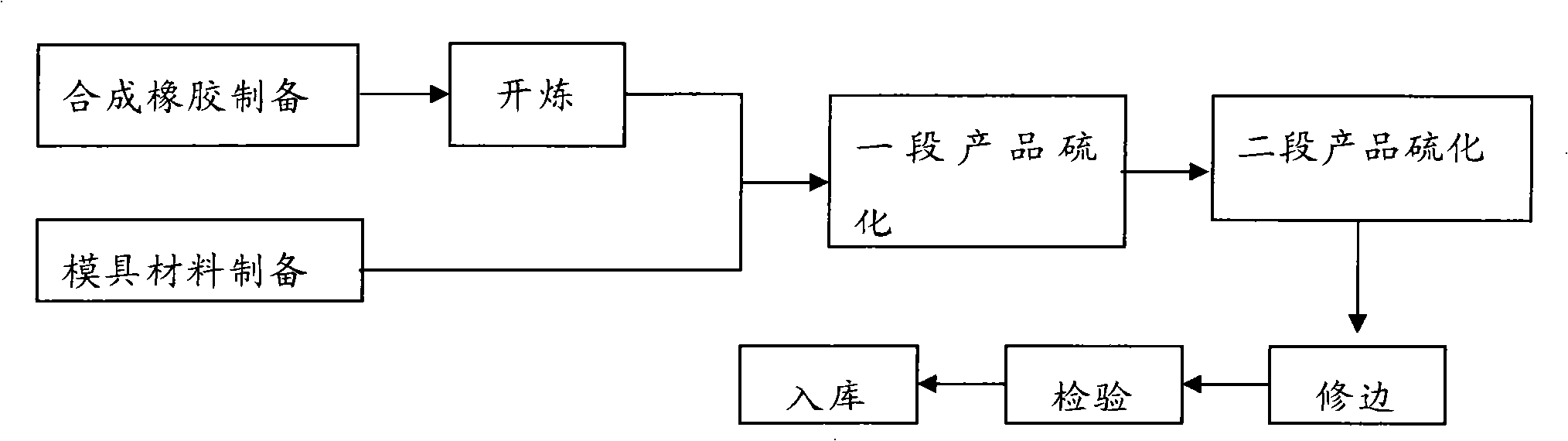

[0066] The manufacturing method of the rubber sealing ring of the water pipeline system is as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com