Alkyd acrylic hybrid latex paint and preparation method thereof

A technology of alkyd, acrylic and latex coatings, applied in the direction of coating, etc., can solve the problems of material performance deterioration, achieve good weather resistance, improve resin compatibility, and good color retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

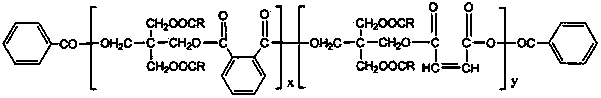

[0037] Embodiment 1. The preparation of alkyd resin

[0038] In a 500ml four-necked flask equipped with a stirring device, an oil-water separator and a thermometer, 60g of soyoleic acid, 17.54g of pentaerythritol, and 1.65g of benzoic acid were successively added, protected by nitrogen gas, stirring and condensed water were started, and the temperature was raised to 180°C within 1h (wherein When the temperature reaches 120°C, add 3g xylene); when the temperature reaches 180°C, start to keep warm, keep warm for 40min, and control the temperature at 180-200°C; add 8.27g phthalic anhydride, 0.27g maleic anhydride and 5.46g di Toluene, after 10 minutes, add the remaining 8.27g phthalic anhydride and 0.27g maleic anhydride; raise the temperature to control the temperature at 210-220°C, keep it for 1h; continue to raise the temperature to control the temperature at 220-230°C, keep it for 1h Start to measure the acid value; when the acid value is less than 17mgKOH / g, start to cool do...

Embodiment 2

[0039] Embodiment 2. Preparation of drier

[0040] Dissolve 8.33g of emulsifier CO-436 in 88.89g of deionized water, add 2.78g of ethylene glycol, 5.56g of cobalt isooctanoate, 22.22g of manganese isooctanoate, and 22.22g of zirconium isooctanoate, disperse at a high speed of 1500r / mim, and stir for 2 hours. Available as a drier for alkyd acrylic hybrid emulsion.

Embodiment 3

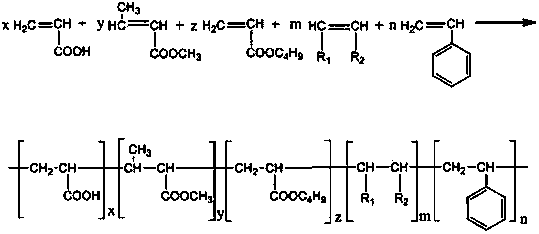

[0041] Example 3. Preparation of Alkyd Acrylic Hybrid Emulsion

[0042] Dissolve 9.6g of alkyd resin in 0.9g of acrylic acid, 10.7g of methyl methacrylate, 10g of styrene, and 15.6g of butyl acrylate mixed monomer for use; , Dissolve 0.18g of sodium bicarbonate in 36g of deionized water, add the mixed monomer dissolved in alkyd resin and stir at 2000r / min for 30min to pre-emulsify; dissolve 0.36g of CO-436 in 18g of deionized water and put it into a stirring device, In a 250ml three-necked flask with a spherical condenser and a thermometer, start stirring at 200r / min and condensate water, raise the temperature to 75°C, add an initiator (0.24g ammonium persulfate + 6g deionized water); when the temperature reaches 78°C, pre-emulsify Put the liquid into a 100ml constant pressure dropping funnel, and start to drop it from the upper end of the condenser tube. After about 3 hours, keep the temperature at 78-80°C; h; cool down to 60°C, add 1.2g of film-forming aid lauryl alcohol es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com