Rubber composition for conducting static electricity for oil storage tank sealing device and production method thereof

A technology of rubber composition and sealing device, which is applied in the field of rubber composition, can solve the problem of inability to produce rubber materials with medium resistance, wear resistance, high strength and good static conductivity, medium resistance, wear resistance, and unsatisfactory strength, Disaster prevention requirements gap and other issues, to achieve the effect of improved safety performance, excellent static conductivity, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

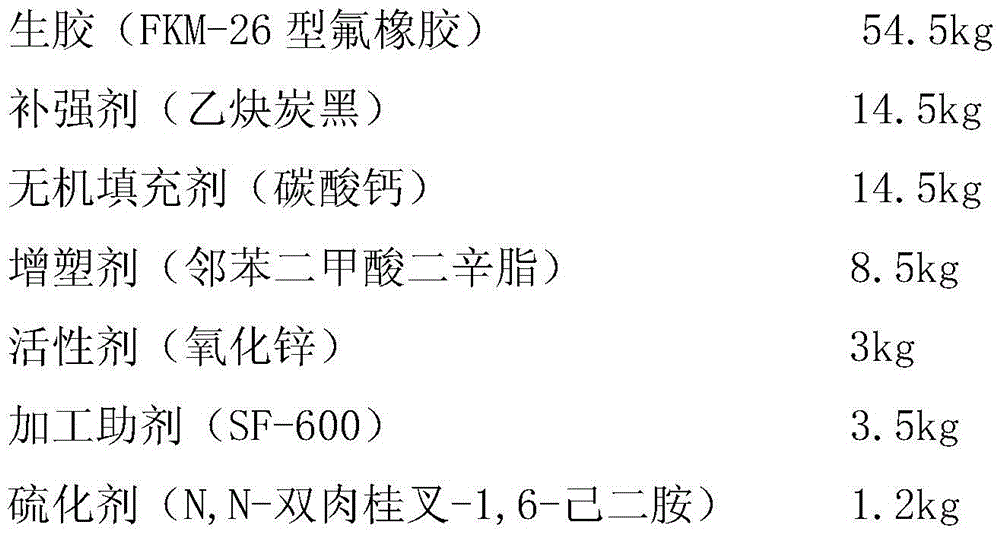

Embodiment 1

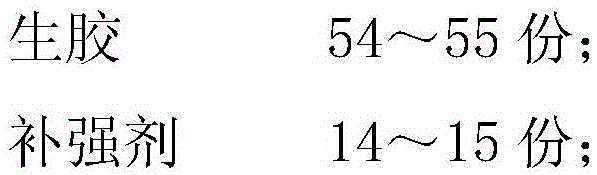

[0019] The rubber composition for conducting static electricity of the oil storage tank sealing device is made of raw materials with the following weights:

[0020]

[0021] It is produced by mixing method. Specifically, the raw rubber, active agent and processing aid are placed in an internal mixer and mixed under pressure (conventional mixing process pressure) for 2 minutes to obtain rubber compound A. Put reinforcing agent, inorganic filler and plasticizer into rubber compound A, and place them in an internal mixer for pressure mixing for 8 minutes to obtain rubber compound B. Put a vulcanizing agent into the rubber compound B, and place it in an internal mixer for pressure mixing for 2 minutes to obtain a rubber compound C. Then put the rubber mixture C in an open mill and mix it evenly, and process it through the thin pass process 6 times, and the next piece can be parked for more than 12 hours.

Embodiment 2

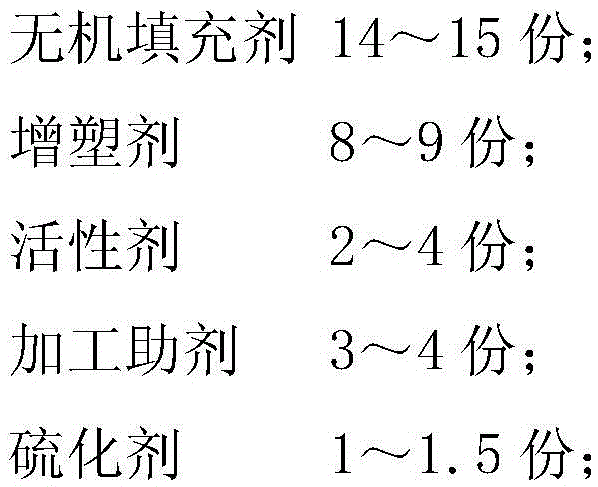

[0023] The rubber composition for conducting static electricity of the oil storage tank sealing device is made of raw materials with the following weights:

[0024]

[0025]

[0026] It is produced by mixing method. Specifically, the raw rubber, active agent and processing aid are placed in an internal mixer and mixed under pressure (conventional mixing process pressure) for 1 minute to obtain rubber compound A. Put the reinforcing agent, inorganic filler and plasticizer into the rubber compound A, and place them in the internal mixer for pressure mixing for 9 minutes to obtain the rubber compound B. Put the vulcanizing agent into the rubber compound B and place it in an internal mixer for pressure mixing for 3 minutes to obtain the rubber compound C. Then put the rubber mixture C in an open mill and mix it evenly, and process it through the thin pass process 6 times, and the next piece can be parked for more than 12 hours.

Embodiment 3

[0028] The rubber composition for conducting static electricity of the oil storage tank sealing device is made of raw materials with the following weights:

[0029]

[0030] The compounding method is used for production, specifically, the raw rubber, active agent and processing aid are placed in an internal mixer for pressure (normal mixing process pressure) and mixed for 3 minutes to obtain compound rubber A. Put reinforcing agent, inorganic filler and plasticizer into rubber compound A, and place them in an internal mixer for mixing under pressure for 6 minutes to obtain compound rubber B. Put the vulcanizing agent into the rubber compound B and place it in an internal mixer for pressure mixing for 5 minutes to obtain the rubber compound C. Then put the rubber mixture C in an open mill and mix it evenly, and process it through the thin pass process 6 times, and the next piece can be parked for more than 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com