A kind of fluorosilicone rubber-metal adhesive and preparation method thereof

A technology of fluorosilicone rubber and adhesives, which is applied in the field of fluorosilicone rubber-metal adhesives and their preparation, can solve problems such as fluctuations in bonding quality and instability of silane coupling agents, reduce shrinkage, improve bonding strength, and excellent Effects of Flexibility and Chemical Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

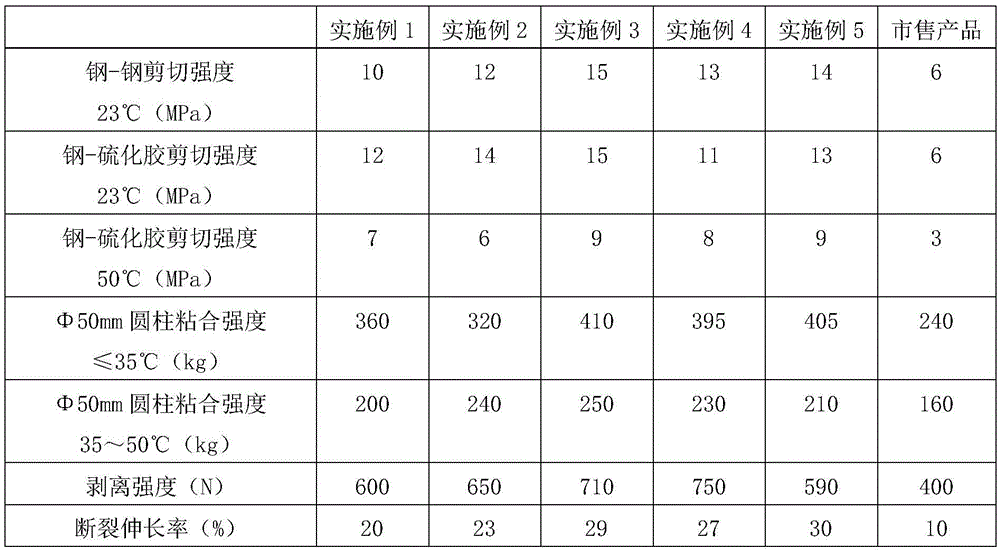

Examples

Embodiment 1

[0022] A fluorosilicone rubber-metal adhesive and a preparation method thereof, comprising in parts by weight: 5 parts of E-40 epoxy resin, 3 parts of liquid polysulfide rubber, 2 parts of silicon dioxide, γ-aminopropyltriethoxy 1 part of silane, 2 parts of chlorosulfonated polyethylene, 1 part of nitrile rubber, 3 parts of mica powder, 2 parts of vinyltriethyloxysilane, 3 parts of dimethylformamide, 1 part of diaminodiphenyl sulfone, 1 part of phthalic anhydride, 3 parts of 2-ethyl-4-methylimidazole, 1 part of ethylene glycol dimethacrylate, 2 parts of ethylenediamine, and 10 parts of dichloromethane.

[0023] The average molecular weight of the above-mentioned liquid polysulfide rubber is 1000; the particle size of the mica powder is 50 μm.

[0024] The preparation method of above-mentioned fluorosilicone rubber-metal adhesive, comprises the following steps:

[0025] Step 1, epoxy resin, liquid polysulfide rubber, silica, γ-aminopropyltriethoxysilane, chlorosulfonated polye...

Embodiment 2

[0029] A fluorosilicone rubber-metal adhesive and a preparation method thereof, comprising in parts by weight: 7 parts of E-42 epoxy resin, 4 parts of liquid polysulfide rubber, 3 parts of silicon dioxide, γ-aminopropyltriethoxy 2 parts of silane, 5 parts of chlorosulfonated polyethylene, 4 parts of nitrile rubber, 5 parts of mica powder, 6 parts of vinyltriethyloxysilane, 5 parts of dimethylformamide, 2 parts of diaminodiphenylsulfone, 3 parts of phthalic anhydride, 4 parts of 2-ethyl-4-methylimidazole, 2 parts of ethylene glycol dimethacrylate, 3 parts of diethylenetriamine, and 13 parts of chloroform.

[0030] The average molecular weight of the above-mentioned liquid polysulfide rubber is 1400; the particle size of the mica powder is 70 μm.

[0031] The preparation method of above-mentioned fluorosilicone rubber-metal adhesive, comprises the following steps:

[0032] Step 1, epoxy resin, liquid polysulfide rubber, silica, γ-aminopropyltriethoxysilane, chlorosulfonated pol...

Embodiment 3

[0036] A fluorosilicone rubber-metal adhesive and a preparation method thereof, comprising in parts by weight: 8 parts of E-42 epoxy resin, 6 parts of liquid polysulfide rubber, 5 parts of silicon dioxide, γ-aminopropyltriethoxy 5 parts of silane, 4 parts of chlorosulfonated polyethylene, 5 parts of nitrile rubber, 4 parts of mica powder, 5 parts of vinyltriethyloxysilane, 6 parts of dimethylformamide, 3 parts of diaminodiphenylsulfone, 2 parts of phthalic anhydride, 4 parts of 2-ethyl-4-methylimidazole, 3 parts of ethylene glycol dimethacrylate, 5 parts of triethylenetetramine, and 15 parts of ethyl acetate.

[0037] The average molecular weight of the above-mentioned liquid polysulfide rubber is 1800; the particle size of the mica powder is 90 μm.

[0038] The preparation method of above-mentioned fluorosilicone rubber-metal adhesive, comprises the following steps:

[0039]Step 1, epoxy resin, liquid polysulfide rubber, silica, γ-aminopropyltriethoxysilane, chlorosulfonated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com