Weather-proof polyolefin wire cable material and preparation method thereof

A wire and cable material, polyolefin technology, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of weather resistance, poor mechanical properties, etc., and achieve the effect of excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

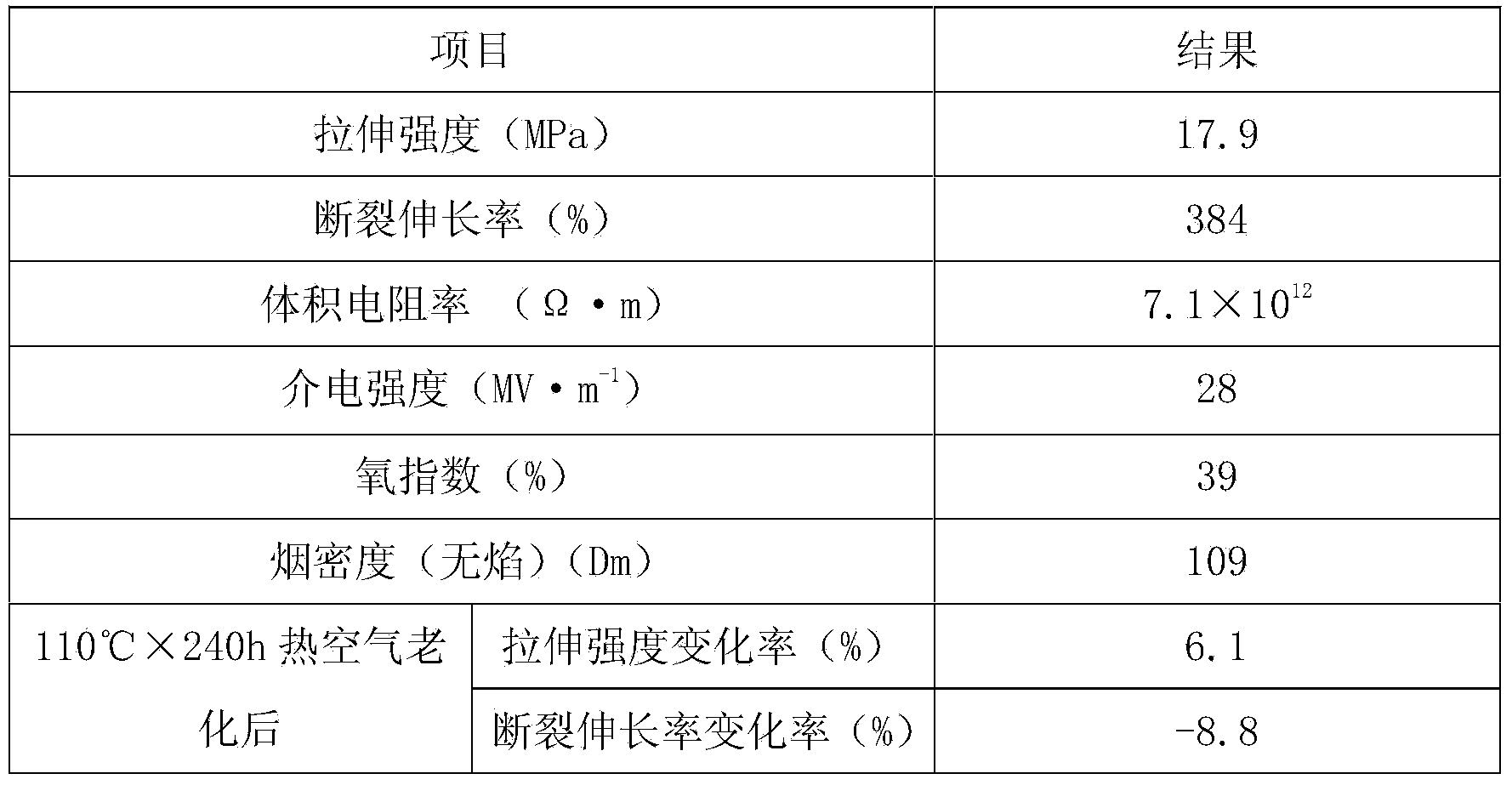

Examples

Embodiment Construction

[0010] A weather-resistant polyolefin wire and cable material, made of the following raw materials by weight (kg): LDPE70, EVA20, SEBS10, magnesium hydroxide 16, stearic acid 2, zinc oxide 1.5, zinc borate 8, tribasic lead sulfate 1.5 , Vinyl triethoxysilane 2, epoxy octyl stearate 6, light stabilizer GW-4800.8, antioxidant 2151, dibutyltin dilaurate 0.6, dicumyl peroxide 0.8, silicon aluminum carbon black 22 , Nano barite 10, nano diatomite 8, composite filler 5.

[0011] The preparation method of described composite filler is as follows: a. get the raw material of following weight (kg): bauxite 12, dolomite 8, sodium tripolyphosphate 4, jade powder 5, ferrocene 2, sodium lauryl sulfate 0.6, volcanic ash 4, aluminum hydroxide 6, barium sulfate whisker 4, calcium stearate 2, mullite 8, polytetrafluoroethylene powder 5, N-2-(aminoethyl)-3-aminopropyltrimethyl Oxysilane 2; b. Calcined bauxite and dolomite at 520°C for 5 hours, cooled to room temperature, mixed with mullite and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com