Full-biodegradable plastic mulching film, preparation method and application thereof

A biodegradable plastic and all-biological technology, applied in botany equipment and methods, applications, plant protection, etc., can solve problems such as early cracking, unsuitable for large-scale promotion, poor constructability of mulch films, etc., and achieve good dispersion and interface binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

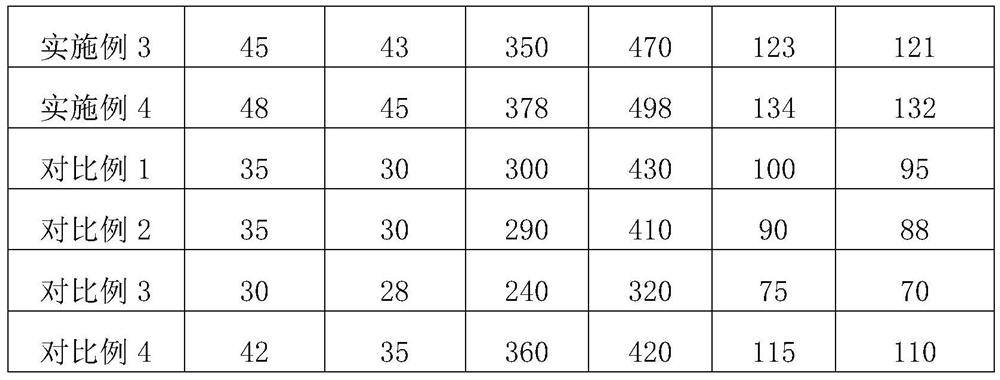

Examples

preparation example Construction

[0037] In the fully biodegradable plastic mulch film according to the present invention, the preparation method of the modified starch includes the following steps: (1) Paste making: adding the starch raw material into an alkaline solution of sodium hydroxide with a pH of 8-9 and mixing and stirring into starch slurry, heated at 80-90°C to become pasty starch slurry, the mass concentration of starch in the starch slurry is 50% to 80%; (2) modification reaction: by weight ratio, in 100 parts of pasty starch slurry , add 10 parts of toluene diisocyanate and ethylene-vinyl acetate copolymer mixed emulsion, 0.2-1 part of stannous octoate and 2-4 parts of polyvinyl alcohol aqueous solution, and then react at 75 ° C to 105 ° C for 10-20 hours to obtain modified starch slurry ; Wherein the mass ratio of toluene diisocyanate and ethylene-vinyl acetate copolymer is 1:0.2~1, the mass concentration of the emulsion is 20-40%; the mass concentration of the polyvinyl alcohol aqueous solution...

Embodiment 1

[0045] (1) Prepare modified starch:

[0046] (1) Paste preparation: the corn starch raw material is added into a sodium hydroxide alkaline solution with a pH of 8, mixed and stirred to form a starch slurry, heated at 80° C. to become a paste starch slurry, and the mass concentration of starch in the starch slurry is 50%;

[0047] (2) Modification reaction: by weight, in 100 parts of pasty starch slurry, add 10 parts of toluene diisocyanate and ethylene-vinyl acetate copolymer mixed emulsion, 0.2 part of stannous octoate and 2 parts of polyvinyl alcohol aqueous solution, Then react at 75°C for 10h to obtain modified starch slurry; wherein the mass ratio of toluene diisocyanate and ethylene-vinyl acetate copolymer is 1:0.2~1, and the mass concentration of the emulsion is 20%; the mass concentration of the polyvinyl alcohol aqueous solution 10%;

[0048] (3) Post-treatment: drying, grinding and sieving the modified starch slurry to obtain modified starch.

[0049] (2) Preparati...

Embodiment 2

[0060] (1) Prepare modified starch:

[0061](1) Paste: the potato starch raw material is added into a sodium hydroxide alkaline solution with a pH of 8.5, mixed and stirred to form a starch slurry, and heated at 85° C. to become a paste-like starch slurry, and the mass concentration of starch in the starch slurry is 60%;

[0062] (2) Modification reaction: by weight, in 100 parts of pasty starch slurry, add 10 parts of toluene diisocyanate and ethylene-vinyl acetate copolymer mixed emulsion, 0.6 part of stannous octoate and 3 parts of polyvinyl alcohol aqueous solution, Then react at 90°C for 15h to obtain modified starch slurry; wherein the mass ratio of toluene diisocyanate and ethylene-vinyl acetate copolymer is 1:0.2~1, and the mass concentration of the emulsion is 30%; the mass concentration of the polyvinyl alcohol aqueous solution 15%;

[0063] (3) Post-treatment: drying, grinding and sieving the modified starch slurry to obtain modified starch.

[0064] (2) Preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com