Low-shrinkage epoxy resin as well as preparation method and application thereof

A low-shrinkage epoxy resin and epoxy resin technology, applied in the field of polymer material preparation, can solve the problems of volume resistivity, tracking resistance, arc resistance, low thermal expansion, etc., and achieve superior process operability, reduce shrinkage, shrinkage small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

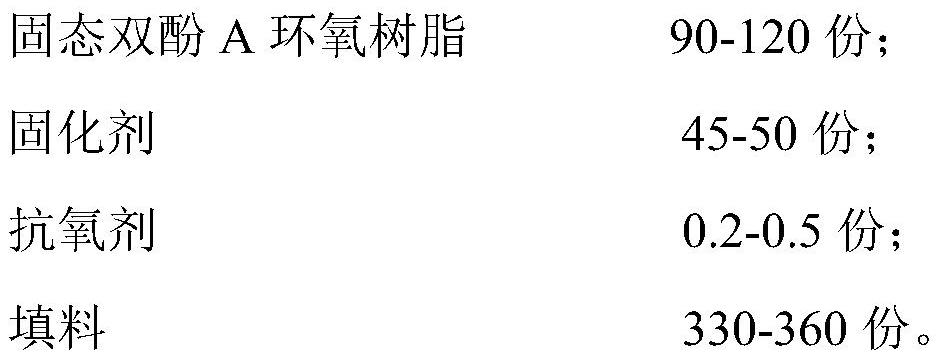

[0035] Embodiment 1 A kind of low-shrinkage epoxy resin, comprises the raw material of following weight part:

[0036] raw material components content Solid bisphenol A epoxy resin - 90 Hardener Modified hexahydrophthalic anhydride 45 antioxidant Antioxidant 703 0.2 filler Electrical alumina filler 330

[0037] Among them, the epoxy equivalent of bisphenol A epoxy resin is 185eq / 100g; the viscosity at 25°C is 2234mPas.

[0038] Preparation method: comprising the following steps:

[0039] (1) First, melt the solid bisphenol A epoxy resin at 130±5°C and set aside; add bisphenol A epoxy resin with 100 times the amount of antioxidant 703 to the antioxidant 703 in the formula, and stir at a high speed Mixer disperses evenly to obtain mixture 1; Add mixture 1 to the mixing tank filled with remaining bisphenol A epoxy resin, stir and disperse evenly to obtain mixture 2;

[0040] (2) Add the electrical alumina filler pre-baked at 130±5...

Embodiment 2

[0042] Embodiment 2 A kind of low-shrinkage epoxy resin, comprises the raw material of following weight portion:

[0043] raw material components content Solid bisphenol A epoxy resin - 120 Hardener Modified hexahydrophthalic anhydride 50 antioxidant Antioxidant 703 0.5 filler Electrical alumina filler 360

[0044] Among them, the epoxy equivalent of bisphenol A epoxy resin is 196eq / 100g; the viscosity at 25°C is 2486mPas.

[0045] Preparation method: comprising the following steps:

[0046] (1) First, melt the solid bisphenol A epoxy resin at 130±5°C and set aside; add bisphenol A epoxy resin with 100 times the amount of antioxidant 703 to the antioxidant 703 in the formula, and stir at a high speed Mixer disperses evenly to obtain mixture 1; Add mixture 1 to the mixing tank filled with remaining bisphenol A epoxy resin, stir and disperse evenly to obtain mixture 2;

[0047] (2) Add the electrical alumina filler pre-baked at 1...

Embodiment 3

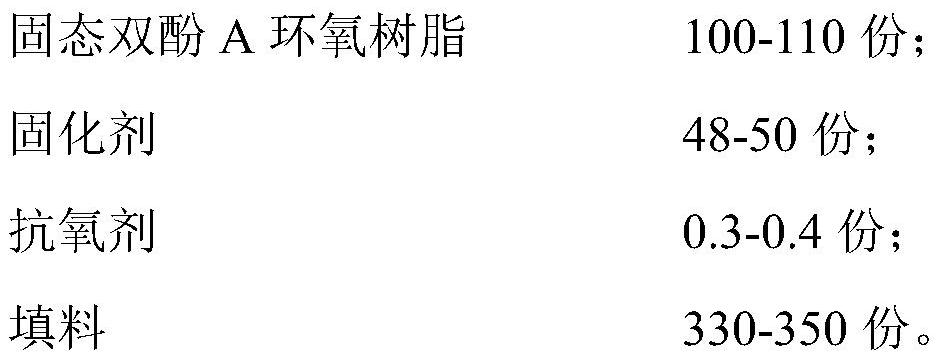

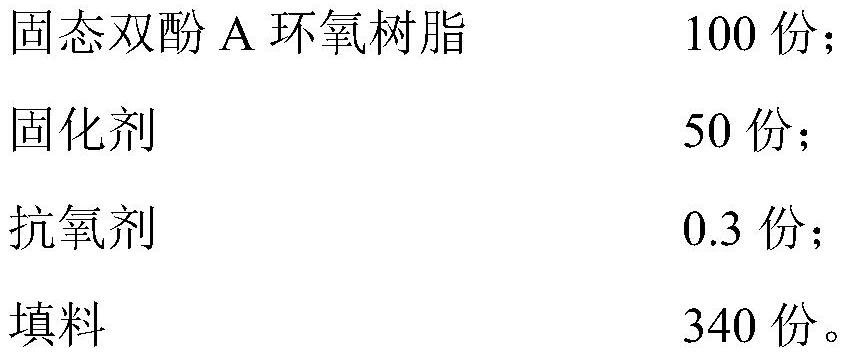

[0049] A kind of low-shrinkage epoxy resin of embodiment 3 comprises the raw material of following weight part:

[0050] raw material components content Solid bisphenol A epoxy resin - 110 Hardener Modified hexahydrophthalic anhydride 48 antioxidant Antioxidant 703 0.4 filler Electrical alumina filler 350

[0051] Among them, the epoxy equivalent of bisphenol A epoxy resin is 183eq / 100g; the viscosity at 25°C is 2342mPas.

[0052]Preparation method: comprising the following steps:

[0053] (1) First, melt the solid bisphenol A epoxy resin at 130±5°C and set aside; add bisphenol A epoxy resin with 100 times the amount of antioxidant 703 to the antioxidant 703 in the formula, and stir at a high speed Mixer disperses evenly to obtain mixture 1; Add mixture 1 to the mixing tank filled with remaining bisphenol A epoxy resin, stir and disperse evenly to obtain mixture 2;

[0054] (2) Add the electrical alumina filler pre-baked at 130...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com