Method and equipment for improving enameled wire insulating paint film removal efficiency

An enameled wire insulation and removal efficiency technology, which is applied in the direction of dismantling/armored cable equipment, line/collector parts, electrical components, etc., can solve the problems of personnel injury, and achieve the effect of accelerating the progress of paint film dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

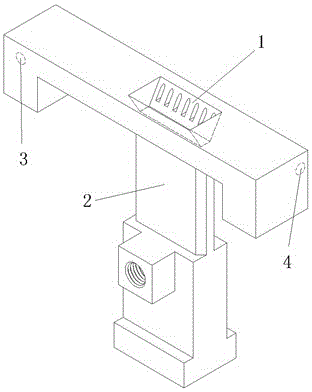

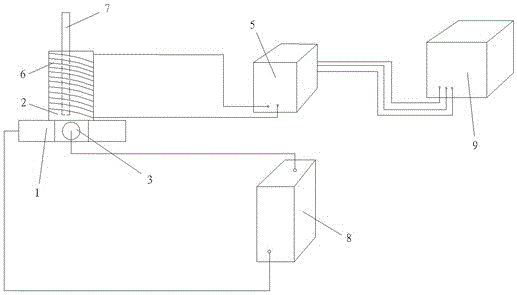

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] Such as Figure 1-2 As shown, the method for promoting enameled wire insulating varnish film removal efficiency of the present invention, it comprises the steps:

[0030] A. Set up an enameled wire soaking tank, and the enameled wire soaking tank is filled with a solution for dissolving insulating varnish.

[0031] Heating equipment to heat the enameled wire placed in the enameled wire soaking tank,

[0032] And the chemical liquid circulation system, which recovers the reacted and unreacted solution in the enameled wire soaking tank;

[0033] B. Induction coils are wound on the outer surface of the enameled wire soaking tank, the heating equipment is connected to both ends of the induction coil and an alternating current with a frequency of 300HZ-1.1MHZ is fed into the induction coil. High frequency, ultra high frequency an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com