High-resistance polypropylene carbonate based composite film material and preparation method thereof

A polypropylene carbonate and composite film technology, which is applied in the field of polymer materials, can solve the problems of opaque aluminum foil, cannot be widely used, and is difficult to recycle, and achieves the effects of simple preparation method, good economic benefits, and reduced greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

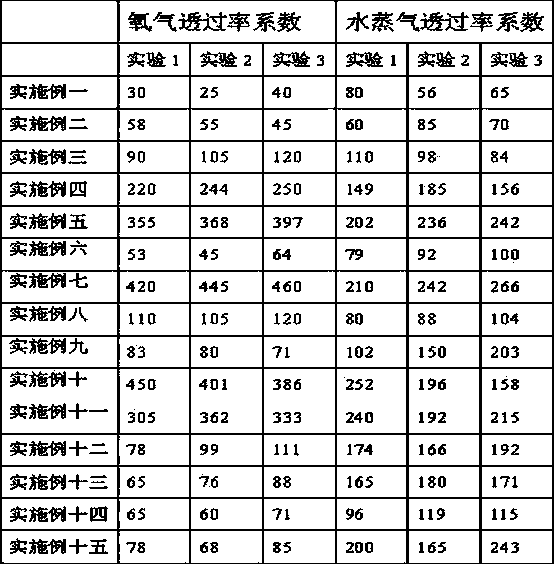

Examples

Embodiment 1

[0045] The preparation of a high-barrier polypropylene carbonate-based composite film material is calculated according to the number of parts by mass: first, 5 parts of polyvinyl alcohol with a degree of polymerization of 500 and an alcoholysis degree of 88% and 0.5 parts of talc powder and 33 parts of deionized Add water into the reaction vessel, heat in a water bath, raise the temperature to 80°C, stir and ultrasonically oscillate, heat at a constant temperature for 6 hours, acetone precipitation and suction filtration, wash with absolute ethanol three times, and dry in a vacuum oven at 80°C to obtain polyvinyl alcohol nano-inserts Layer the composite material and crush it; then dry 5 parts of polyethylene-vinyl alcohol particles in a vacuum oven at 80°C for 24 hours, and mix and stir the polyethylene-vinyl alcohol and the crushed polyvinyl alcohol nano-intercalation composite material at room temperature Homogeneously, melt-blended to obtain a plasticized polyvinyl alcohol n...

Embodiment 2

[0047] The difference between this embodiment and the first embodiment is that: polyvinyl alcohol is 10 parts, its degree of polymerization is 800, alcoholysis degree is 90%, layered silicate is 5 parts of montmorillonite powder, and deionized water is 150 parts parts, constant temperature heating time is 8h, plasticizer is 10 parts of polyester polyurethane particles, polypropylene carbonate is 90 parts, and its number average molecular weight is 100000Da.

Embodiment 3

[0049] The difference between this embodiment and Embodiment 1 is that: polyvinyl alcohol is 15 parts, its degree of polymerization is 1500, alcoholysis degree is 95%, layered silicate is 5 parts of chlorite powder, and deionized water is 400 parts parts, constant temperature heating time is 10h, plasticizer is 20 parts of polyether polyurethane, polypropylene carbonate is 80 parts, and its number average molecular weight is 150000Da.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com