Quasi-solid electrolyte as well as preparation method and application thereof

An electrolyte, quasi-solid-state technology, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve the problems of interface stability and affect the cycle stability of lithium anodes, and achieve excellent mechanical properties and chemical/electrochemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

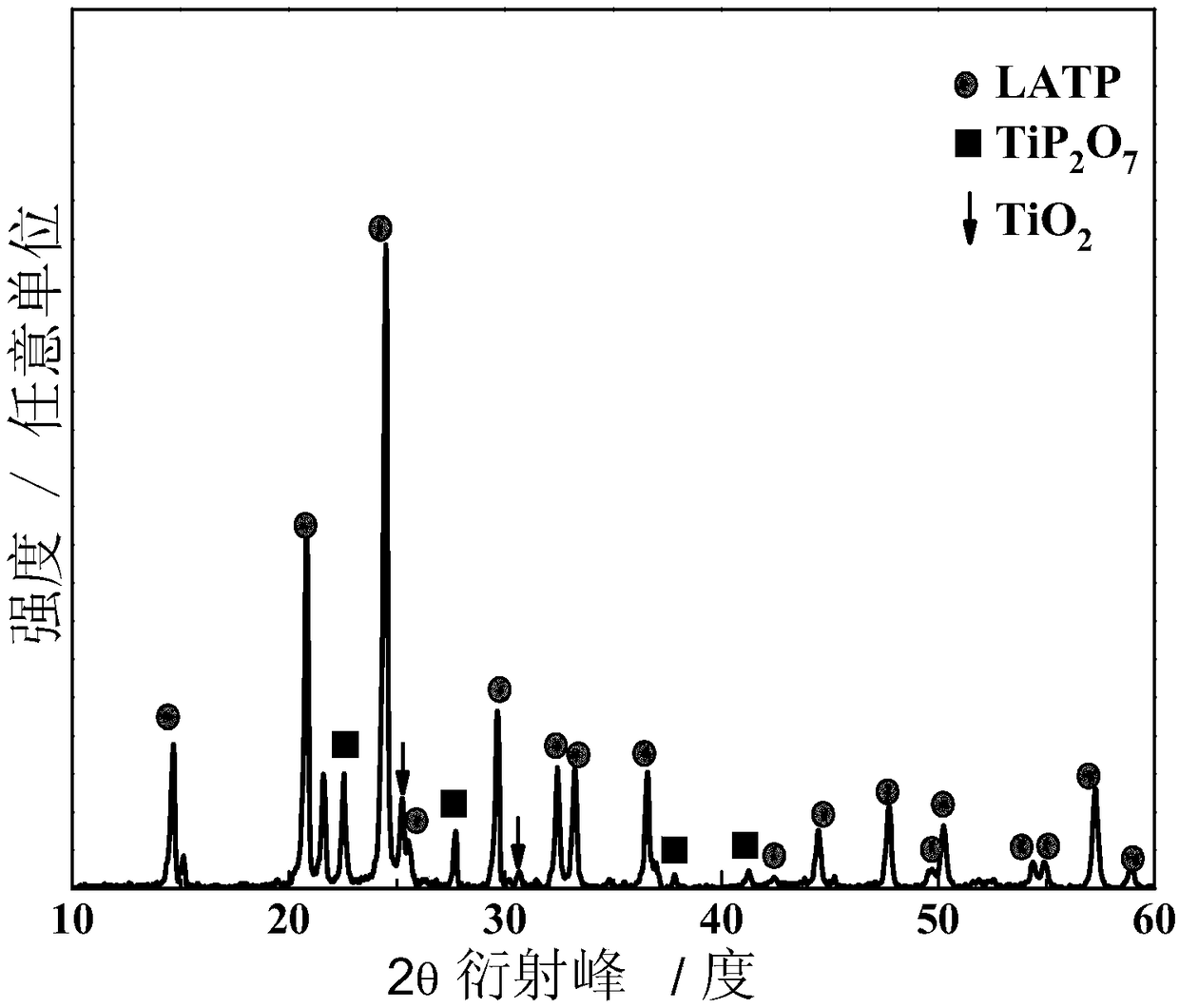

[0066] The ceramic electrolyte was prepared by the sol-gel method. 19.6mL of 25% ammonia water was added dropwise to 10mL of tetraisopropyl titanate, and a precipitate was obtained after magnetic stirring for 1 hour. The precipitate was filtered and dispersed in 40mL of deionized water. Stir evenly, then add 80 mL of oxalic acid with a concentration of 1 mol / L, and stir well until the precipitate is completely dissolved to obtain solution A; 1.832 g of LiNO 3 , 2.212 grams of Al(NO 3 ) 3 9H 2 O, 7.751 g (NH 4 ) 2 HPO 4 Add it into the above-mentioned solution A in the step, and obtain solution B after thorough stirring; dissolve 6 grams of cetyltrimethylammonium bromide in 40 mL of absolute ethanol, and stir at 40°C for 2 hours to obtain solution C; Add C to solution B, stir well at 80°C to obtain a colloidal precursor, then place the precursor in a tube furnace, raise the temperature to 650°C in an air atmosphere at a rate of 2°C / min, and heat it under argon Roasting in...

Embodiment 2

[0082] The ceramic electrolyte was prepared by the sol-gel method. 19.6mL of 25% ammonia water was added dropwise to 10mL of tetraisopropyl titanate, and a precipitate was obtained after magnetic stirring for 1 hour. The precipitate was filtered and dispersed in 40mL of deionized water. Stir evenly, then add 80 mL of oxalic acid with a concentration of 1 mol / L, and stir well until the precipitate is completely dissolved to obtain solution A; 1.761 g of LiNO 3 , 2.581 grams of Al(NO 3 ) 3 9H 2 O, 7.751 g (NH 4 ) 2 HPO 4 Add it to the above solution in the step, and stir to obtain solution B; dissolve 6 grams of cetyltrimethylammonium bromide in 40 mL of absolute ethanol, and stir at 40°C for 2 hours to obtain solution C; Add it into solution B, stir well at 80°C to obtain a colloidal precursor, then place the precursor in a tube furnace, raise the temperature to 600°C in an air atmosphere at a rate of 2°C / min, and heat it under an argon atmosphere The ceramic electrolyte ...

Embodiment 3

[0086] The ceramic electrolyte was prepared by the sol-gel method. 19.6mL of 25% ammonia water was added dropwise to 10mL of tetraisopropyl titanate, and a precipitate was obtained after magnetic stirring for 1 hour. The precipitate was filtered and dispersed in 40mL of deionized water. Stir evenly, then add 80 mL of oxalic acid with a concentration of 1 mol / L, and stir well until the precipitate is completely dissolved to obtain solution A; 1.902 g of LiNO 3 , 1.843 g Al(NO 3 ) 3 ·6H 2 O, 7.751 g (NH 4 ) 2 HPO 4 Add it to the above solution in the step, and stir to obtain solution B; dissolve 6 grams of cetyltrimethylammonium bromide in 40 mL of absolute ethanol, and stir at 40°C for 2 hours to obtain solution C; Add it into solution B, stir well at 80°C to obtain a colloidal precursor, then place the precursor in a tube furnace, raise the temperature to 550°C in an air atmosphere at a rate of 2°C / min, and heat it under an argon atmosphere The ceramic electrolyte was ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com