Modified polypropylene carbonate based polyurethane water-based coating agent applied to leather and preparation method of water-based coating agent

A polypropylene carbonate-based polyurethane and polypropylene carbonate technology, applied in the field of leather finishing agent polymer materials, can solve the problems of enhancing the adhesion of the bottom layer, accelerating the speed of film formation, and poor adhesion of the bottom layer, achieving Enhance the adhesion, accelerate the speed of film formation, and have good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

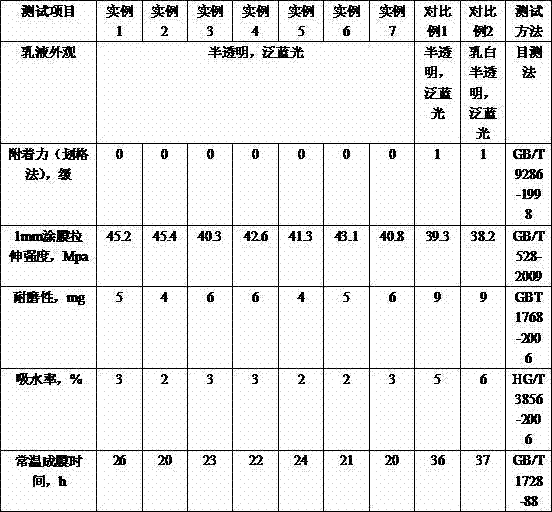

Examples

Embodiment 1

[0025] Weigh 100 parts of polypropylene carbonate polyols with a molecular weight of 1000 according to the mass fraction, dehydrate first, then add 60 parts of hexamethylene diisocyanate and 0.05 parts of organotin catalyst, heat up to 50°C, react for 5 hours, and cool down to At 40°C, add 6 parts of dimethylol propionic acid, raise the temperature to 50°C, react for 5 hours, cool down to 40°C, add 1 part of epoxy resin of model E-44, react at 80°C for 0.1h, and cool down to 0 ℃, add 0.5 parts of triethylamine and 0.5 parts of acetone, stir evenly, then add 1 part of chain extender isophorone diamine, then add deionized water to adjust the solid content to 30%, and emulsify at 0 ℃ for 0.1h , remove acetone under reduced pressure to obtain the modified polypropylene carbonate-based polyurethane water-based finishing agent for leather of the present invention.

Embodiment 2

[0027] Weigh 100 parts of polypropylene carbonate polyol with a molecular weight of 2000 according to the mass fraction, dehydrate first, then add 40 parts of toluene diisocyanate and 0.1 part of dibutyltin dilaurate, heat up to 85°C, react for 1 hour, and cool down to 40°C , add 12 parts of dimethylol butyric acid half ester, heat up to 70°C, react for 1h, cool down to 40°C, add 5 parts of epoxy resin with model E-51, react at 80°C for 0.1h, cool down to 5°C, add 8 parts of dimethylcyclohexylamine and 20 parts of acetone, stir evenly, then add 3 parts of chain extender isophorone diamine, then add deionized water to adjust the solid content to 30%, at 0°C The emulsification reaction was carried out for 2 hours, and the acetone was removed under reduced pressure to obtain the modified polypropylene carbonate-based polyurethane water-based finishing agent for leather of the present invention.

Embodiment 3

[0029] Weigh 100 parts of polypropylene carbonate polyol with a molecular weight of 1500 according to the mass fraction, first dehydrate, then add 65 parts of 4,4'-diphenylmethane diisocyanate and 1 part of dibutyltin dilaurate, and heat up to 80°C , react for 1 hour, cool down to 40°C, add 16 parts of dimethylol propionic acid, heat up to 70°C, react for 2 hours, cool down to 40°C, add 15 parts of E-20 epoxy resin, and react at 70°C 2h, cool down to 10°C, add 18 parts of tripropylamine, 40 parts of acetone, stir evenly, then add 4 parts of chain extender isophorone diamine, then add deionized water to adjust the solid content to 30%, at 5°C After the emulsification reaction for 0.5 h, the acetone was removed under reduced pressure to obtain the modified polypropylene carbonate-based polyurethane water-based finishing agent for leather of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com