Polypropylene carbonate composite material for 3D printing and preparation method thereof

A polypropylene carbonate and composite material technology, applied in the direction of additive processing, etc., can solve the problems of low strength, limited application range, and low glass transition temperature of PPC, achieve good dimensional stability, and improve interface compatibility , the effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

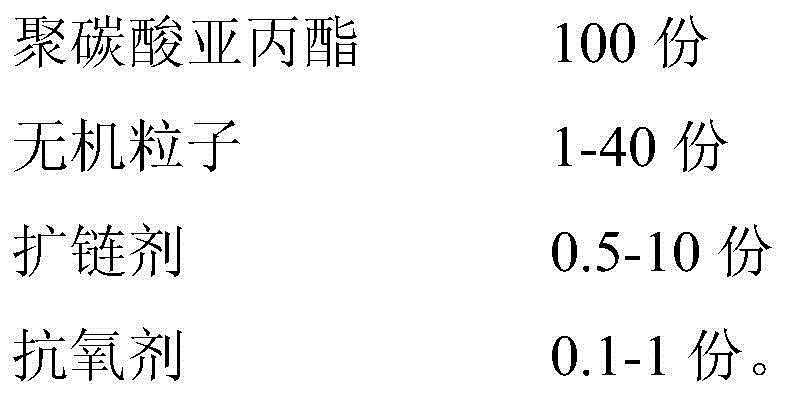

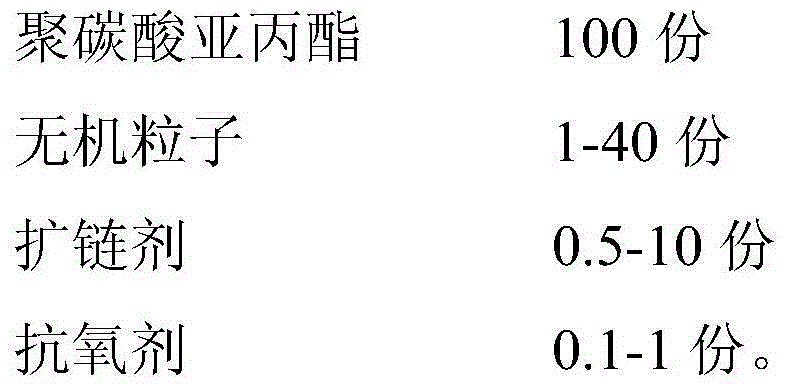

Method used

Image

Examples

Embodiment 1

[0043] (1) Grinding and sieving organic montmorillonite 1.24TL (Nanocor, USA) (400 meshes), and fully drying (the drying temperature is 80°C, and the drying time is 24 hours);

[0044] (2) Polypropylene carbonate (the number-average molecular weight of the polypropylene carbonate is 90,000) is placed in a forced air drying oven at 45°C and fully dried for 48 hours;

[0045] (3) 100 parts by weight of polypropylene carbonate fully dried, 7 parts by weight of 1.24TL, 1 part by weight of p-toluene diisocyanate, 0.5 part by weight of triphenylmethane triisocyanate and 0.5 part by weight of antioxidant 1010, at high speed Mix in mixer for 5 minutes (the rotating speed of high-speed mixer is 750r / min), obtain compound;

[0046] (4) Extrude and wire-draw the mixture through a twin-screw extruder to obtain a 3D printing wire material (that is, a polypropylene carbonate composite material for 3D printing); wherein the screw speed of the twin-screw extruder is 400r / min ; The temperatur...

Embodiment 2

[0049] (1) Grinding and sieving the KH550-modified nano-silica (400 mesh), and fully drying (the drying temperature is 80°C, and the drying time is 24 hours);

[0050] (2) Polypropylene carbonate (the number-average molecular weight of the polypropylene carbonate is 90,000) is placed in a forced air drying oven at 45°C and fully dried for 48 hours;

[0051] (3) 100 parts by weight of fully dried polypropylene carbonate, 3 parts by weight of KH550 modified nano silicon dioxide, 1.2 parts by weight of diphenylmethane diisocyanate, 0.3 parts by weight of dimethyltriphenylmethane tetraisocyanate And 0.5 weight part antioxidant 1010, mixed 5 minutes in high-speed mixer (the rotating speed of high-speed mixer is 750r / min);

[0052] (4) Extrude and wire-draw the mixture through a twin-screw extruder to obtain a 3D printing wire material (that is, a polypropylene carbonate composite material for 3D printing); wherein the screw speed of the twin-screw extruder is 400r / min ; The temper...

Embodiment 3

[0056] (1) Organic montmorillonite 1.34TCN (U.S. NANOCOR company) and light calcium carbonate are pulverized, sieved (the number of meshes is 400 meshes), and fully dried (the drying temperature is 80°C, and the drying time is 24 hours );

[0057] (2) Polypropylene carbonate (the number-average molecular weight of the polypropylene carbonate is 90000) is placed in a blast drying oven at 50°C and fully dried for 48 hours;

[0058] (3) fully dry 100 parts by weight polypropylene carbonate, 5 parts by weight organic montmorillonite 1.34TCN, 20 parts by weight light calcium carbonate, 5 parts by weight styrene-maleic anhydride copolymer (Nantong Rizhisheng Polymer New Material Technology Co., Ltd., SMA-020) and 0.5 parts by weight of antioxidant 168, mixed in a high-speed mixer for 5 minutes (the rotating speed of the high-speed mixer is 750r / min);

[0059] (4) Extrude and wire-draw the mixture through a twin-screw extruder to obtain a 3D printing wire material (that is, a polypr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com