Polypropylene carbonate type polyurethane resin as well as preparation method and application thereof

A technology of polypropylene carbonate and polypropylene carbonate glycol, applied in textiles and papermaking, etc., can solve undisclosed problems, and achieve the effect of reducing demand, realizing effective utilization, and excellent hydrolysis resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

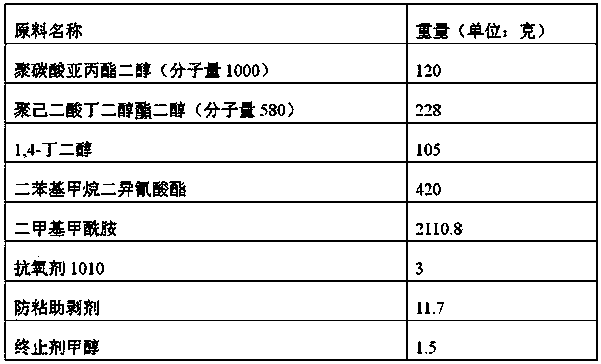

[0040] The raw materials and weights used in this example are shown in Table 1.

[0041] Table 1

[0042]

[0043] The preparation steps of the polypropylene carbonate type polyurethane resin of this embodiment are as follows:

[0044] 1) Dehydrate the polypropylene carbonate glycol and polybutylene adipate glycol;

[0045] 2) Put 450g of dimethylformamide, 3g of antioxidant 1010, 120g of polypropylene carbonate glycol, 228g of polybutylene adipate glycol, and 105g of 1,4-butanediol into the reactor. Stir evenly at 50-55℃;

[0046] 3) Put 420g of diphenylmethane diisocyanate into the reactor in batches, and dilute with 1660.8g of dimethylformamide in batches, strictly control the reaction temperature between 65-70℃, react at normal pressure for 10 hours, after the viscosity is qualified , Add terminator methanol. After the reaction is completed, 11.7 g of the anti-sticking and stripping aid is added and stirred uniformly to obtain the polypropylene carbonate type polyurethane resin o...

Embodiment 2

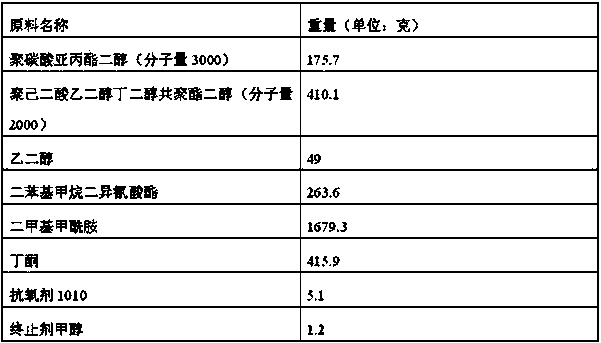

[0048] The raw materials and weights used in this example are shown in Table 2 below.

[0049] Table 2

[0050]

[0051] The preparation steps of the polypropylene carbonate type polyurethane resin of this embodiment are as follows:

[0052] 1) Dehydrate the poly(propylene carbonate) glycol, poly(butylene adipate glycol) and poly(ethylene glycol adipate butylene glycol) copolyester glycol;

[0053] 2) Combine 450g of dimethylformamide, 3g of antioxidant 245, 300g of polypropylene carbonate glycol, 360g of polybutylene adipate glycol, and 60g of polyethylene adipate butylene glycol. Put polyester diol and 15g ethylene glycol into the reactor, stir well at 55-60℃;

[0054] 3) Put 240.6g of diphenylmethane diisocyanate into the reactor in batches, and dilute with 1063.2g of dimethylformamide and 504.6g of methyl ethyl ketone in batches, strictly control the reaction temperature between 70-75℃, and react under normal pressure After 12 hours, the viscosity is qualified, add the terminator ...

Embodiment 3

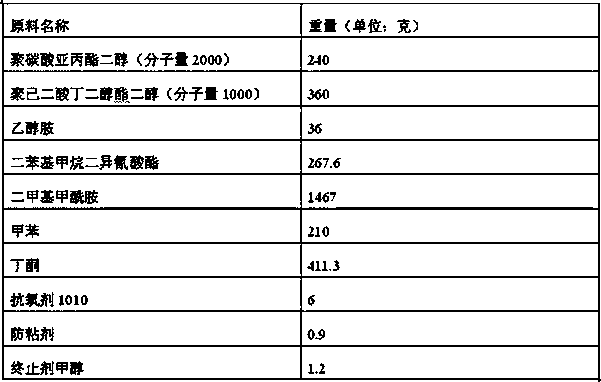

[0056] The raw materials and weights used in this example are shown in Table 3 below.

[0057] table 3

[0058]

[0059] The preparation steps of the polypropylene carbonate type polyurethane resin of this embodiment are as follows:

[0060] 1) Dehydrate the polypropylene carbonate glycol and polybutylene adipate glycol;

[0061] 2) Put 450g of dimethylformamide, 6g of antioxidant 1010, 240g of polypropylene carbonate glycol, 360g of polybutylene adipate glycol, and 36g of ethanolamine into the reactor, stir well at 55-60℃ ;

[0062] 3) Put 267.6g of diphenylmethane diisocyanate into the reactor in batches, and dilute with the remaining dimethylformamide, toluene, and methyl ethyl ketone in batches, strictly control the reaction temperature between 80-85℃, and react at normal pressure for 12 When the viscosity is qualified after hours, add the terminator methanol. After the reaction is completed, 0.9 g of anti-sticking agent is added and stirred uniformly to obtain the polypropylene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com