Composition for preparing expandable polypropylene carbonate and expandable polypropylene carbonate prepared therefrom

A technology of polypropylene carbonate and composition, which is applied in the field of composition and foamable polypropylene carbonate prepared therefrom, and can solve problems such as inability to maintain initial shape and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

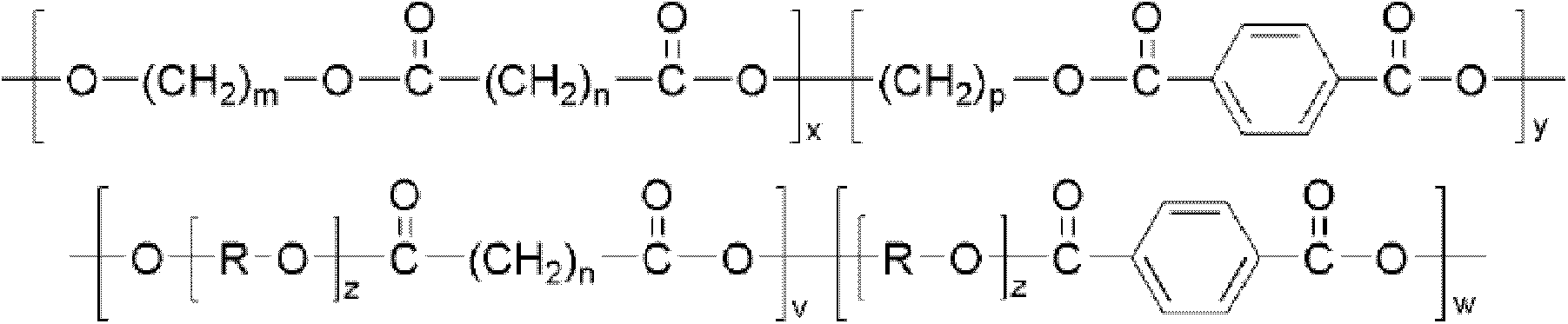

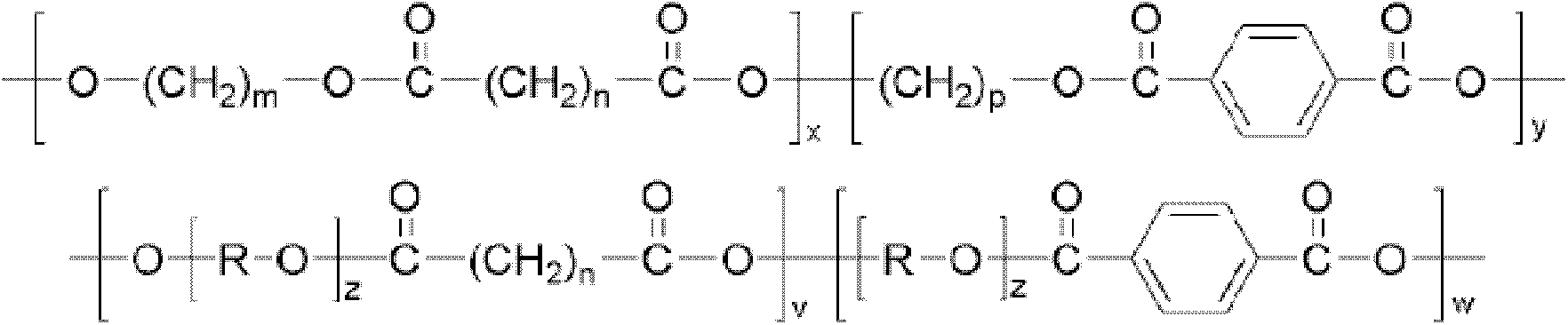

Method used

Image

Examples

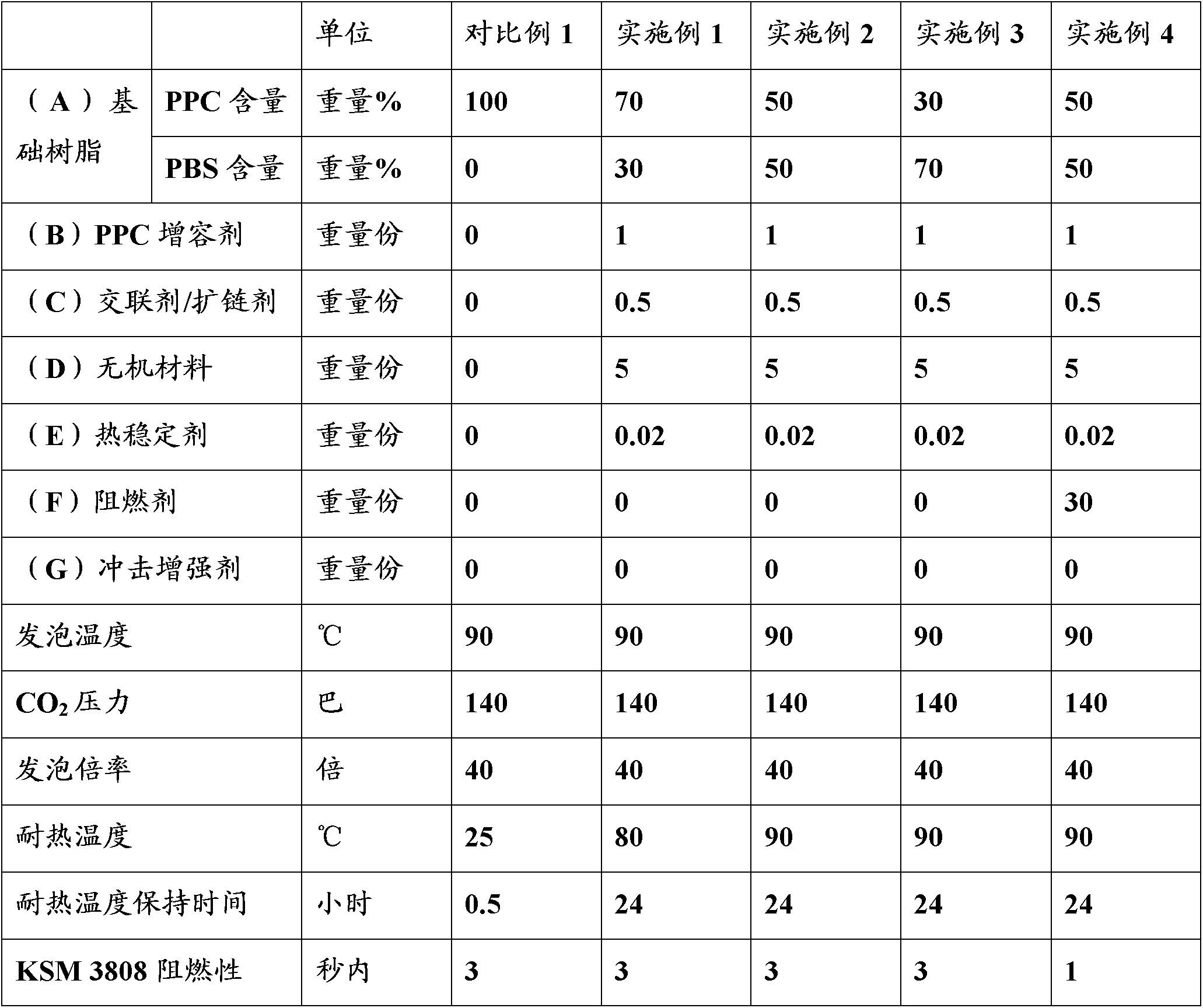

Embodiment 1

[0041] 100 parts by weight of a base resin composed of 70% by weight of polypropylene carbonate (molecular weight: 150000) and 30% by weight of polybutylene succinate (PBS, molecular weight: 170000), 1 part by weight of polypropylene carbonate Ester compatibilizer (a polypropylene carbonate copolymer, molecular weight: 150000, SK Energy Company), 0.5 parts by weight of p-maleimidophenylisocyanate (PMPI), 5 parts by weight of CaCO 3 and 0.02 parts by weight of a heat stabilizer (Songnox 1076, SongWon Company), and extruded through a twin-screw extruder to form pellets. Feed the produced pellets and then carbon dioxide into the main reactor, raise the temperature from room temperature to 80°C, keep the supercritical carbon dioxide state for 1 hour to allow supercritical carbon dioxide to permeate into the pellets, and then discharge through the exhaust port Carbon dioxide gas, thus forming foam. The foaming results are tabulated in Table 1.

Embodiment 2

[0043] Mix 100 parts by weight of base resin, 1 part by weight of polypropylene carbonate compatibilizer (a poly Propylene carbonate copolymer, molecular weight: 150000, SK Energy Company), 0.5 parts by weight of PMPI, 5 parts by weight of CaCO 3 and 0.02 parts by weight of a heat stabilizer (Songnox 1076, SongWon Company), and extruded through a twin-screw extruder to form pellets. Feed the produced pellets and then carbon dioxide into the main reactor, raise the temperature from room temperature to 80°C, keep the supercritical carbon dioxide state for 1 hour to allow supercritical carbon dioxide to permeate into the pellets, and then discharge through the exhaust port Carbon dioxide gas, thus forming foam. The foaming results are tabulated in Table 1.

Embodiment 3

[0045] 100 parts by weight of base resin, 1 part by weight of polypropylene carbonate compatibilizer (a poly Propylene carbonate copolymer, molecular weight: 150000, SK Energy Company), 0.5 parts by weight of PMPI, 5 parts by weight of CaCO 3 and 0.02 parts by weight of a heat stabilizer (Songnox 1076, SongWon Company), and extruded through a twin-screw extruder to form pellets. Feed the produced pellets and then carbon dioxide into the main reactor, raise the temperature from room temperature to 80°C, keep the supercritical carbon dioxide state for 1 hour to allow supercritical carbon dioxide to permeate into the pellets, and then discharge through the exhaust port Carbon dioxide gas, thus forming foam. The foaming results are tabulated in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com