Preparation method of high-thermal-insulation/soil-moisture-preservation degradable agricultural mulching film material

A technology of agricultural mulch film and high heat preservation, which is applied in the field of preparation of degradable agricultural mulch film materials with high heat preservation and moisture retention, can solve the problems of slow promotion progress, low glass transition temperature, and poor film-forming properties, and achieve stable film blowing process, blown film The effect of controllable specifications and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, weigh the raw materials for the anti-degradation masterbatch extrusion experiment. The mass percentage of each substance in the total mass of the anti-degradation masterbatch is: 75% of PBAT, 10% of antioxidant 126, 5% of light stabilizer zinc oxide, 10% Anti-hydrolysis agent carbodiimide; set screw temperature to 160°C, 165°C, 170°C, 175°C, 175°C, 180°C, 185°C, 185°C, 175°C, 170°C, head temperature to 175°C , The feeding rate is 5kg / h. The anti-degradation masterbatch was obtained by extrusion, dried at 85°C for 6 hours, and set aside.

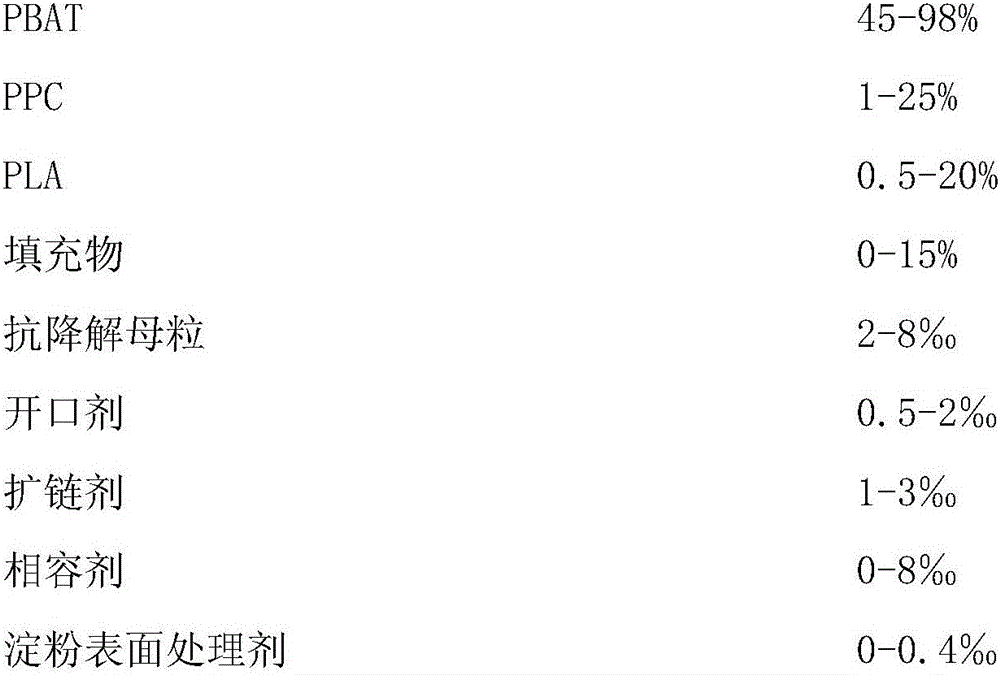

[0023] Secondly, the mass percentage of raw materials used in the preparation process of PPC / PLA modified degradable plastic PBAT is:

[0024]

[0025]

[0026] Again, weigh PBAT, PPC, PLA, and anti-degradation masterbatch according to the above mass percentage, and dry at 85°C for 5-12 hours according to the material characteristics. After cooling to room temperature, perform mechanical mixing with a high-mixing mixer, a...

Embodiment 2

[0029] First, weigh the raw materials for the anti-degradation masterbatch extrusion experiment. The mass percentage of each substance in the total mass of the anti-degradation masterbatch is: 75% of PBAT, 10% of antioxidant 126, 5% of light stabilizer zinc oxide, 10% Anti-hydrolysis agent carbodiimide; set screw temperature to 160°C, 165°C, 170°C, 175°C, 175°C, 180°C, 185°C, 185°C, 175°C, 170°C, head temperature to 175°C , The feeding rate is 10kg / h. The anti-degradation masterbatch was obtained by extrusion, dried at 85°C for 6 hours, and set aside.

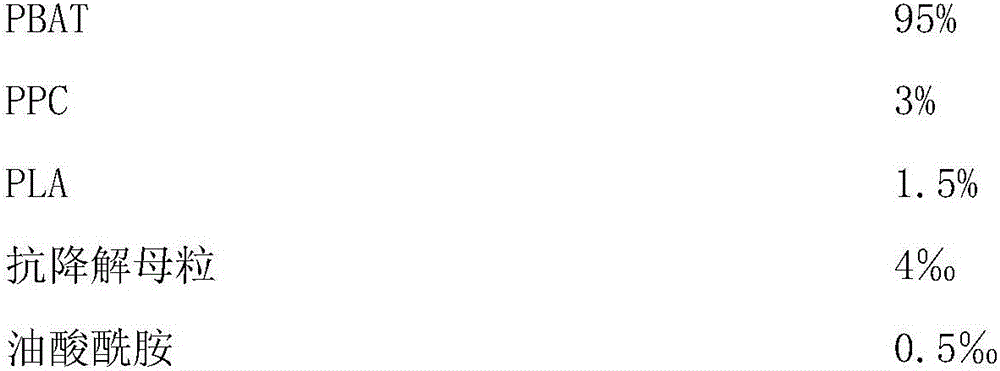

[0030] Secondly, the mass percentage of raw materials used in the preparation process of PPC / PLA modified degradable plastic PBAT is:

[0031]

[0032] Again, weigh PBAT, PPC, PLA, and anti-degradation masterbatch according to the above mass percentage, and dry at 85°C for 5-12 hours according to the material characteristics. After cooling to room temperature, perform mechanical mixing with a high-mixing mixer, and set asid...

Embodiment 3

[0035]First, weigh the raw materials for the anti-degradation masterbatch extrusion experiment. The mass percentage of each substance in the total mass of the anti-degradation masterbatch is: 75% of PBAT, 7% of antioxidant 126, 3% of light stabilizer titanium dioxide, 15% of Anti-hydrolysis agent phenyl glycidyl ether; set screw temperature to 160°C, 165°C, 170°C, 175°C, 175°C, 180°C, 185°C, 185°C, 175°C, 170°C, head temperature to 175°C , The feeding rate is 15kg / h. The anti-degradation masterbatch was obtained by extrusion, dried at 85°C for 6 hours, and set aside.

[0036] Secondly, the mass percentage of raw materials used in the preparation process of PPC / PLA modified degradable plastic PBAT is:

[0037]

[0038] Again, weigh PBAT, PPC, PLA, and anti-degradation masterbatch according to the above mass percentage, and dry at 85°C for 5-12 hours according to the material characteristics. After cooling to room temperature, perform mechanical mixing with a high-mixing mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com