Poly-2,5-furandicarboxylic acid glycol ester composite material and preparation method thereof

A technology of ethylene furandicarboxylate and polybutylene succinate, which is applied in the field of polyester and can solve problems such as brittleness of PEF

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

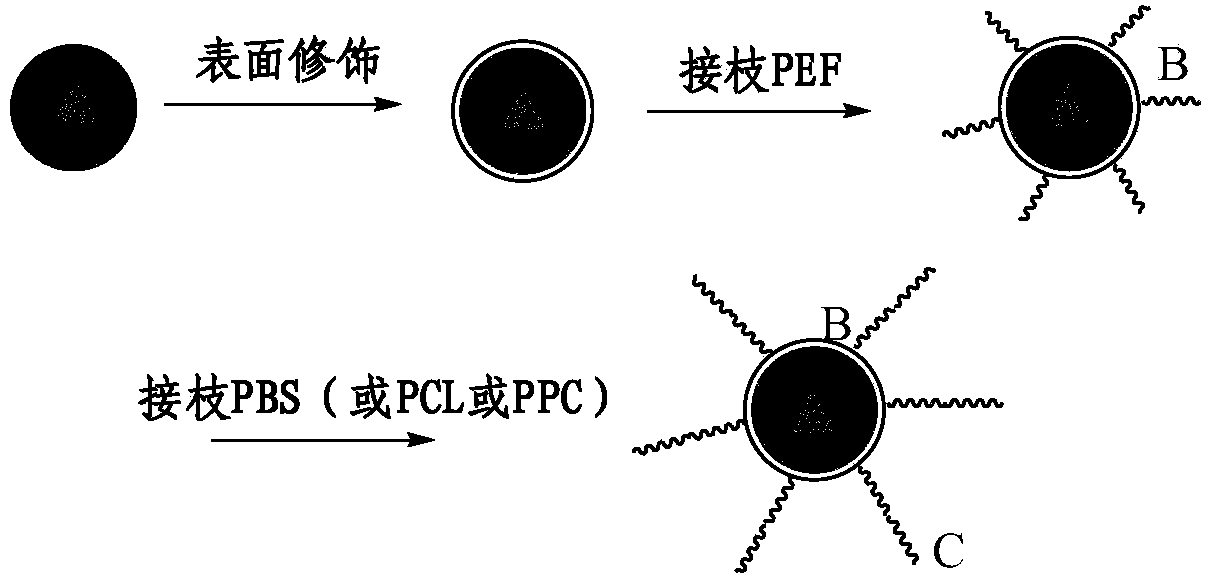

[0043] The present invention also provides a preparation method of the above-mentioned auxiliary agent, comprising: A) mixing a carrier, a silane coupling agent with an amino group at the end, and a second organic solvent, and reacting by heating to obtain surface-modified cellulose beads or cellulose Whiskers; B) Mix the surface-modified cellulose beads or cellulose whiskers, tetrachloroethane, diacid chloride with the second polyethylene 2,5-furandicarboxylate, after heating and reacting, add The second polymer, after continuing to react, obtains an auxiliary agent; the carrier is cellulose beads or cellulose whiskers; the second polymer is selected from polybutylene succinate, polycaprolactone and polycarbonate One or more of propylene esters.

[0044] Wherein, the cellulose beads, the cellulose whiskers, the silane coupling agent with amino groups at the end, the second polyethylene 2,5-furandicarboxylate and the second polymer are all the same as above, and are not mentio...

Embodiment 1

[0083] 1.1 In the reactor, add dry cellulose beads with a particle size of 20-100 μm, 3-aminopropyltriethoxysilane, oleic acid (20% of the mass of cellulose beads) and 200ml of toluene, 3-aminopropyl The mass of triethoxysilane is 20% of the mass of cellulose beads, and nitrogen gas is introduced as a protective gas. After stirring rapidly for 30 minutes, it is heated to 90°C, and the stirring reaction is continued for 420 minutes. The reaction product dispersion is evaporated by rotary evaporation, and the solid is washed and after filtration, the surface-modified cellulose beads were obtained.

[0084] 1.2 Add tetrachloroethane and excess diacid chloride to the reactor, heat to 40°C, add the tetrachloroethane dispersion of surface-modified cellulose beads obtained in 1.1 dropwise, react for 4 hours, and then drop The weight average molecular weight is 1×10 3 ~1×10 4 polyethylene 2,5-furandicarboxylate tetrachloroethane solution (the quality of polyethylene 2,5-furandicarbo...

Embodiment 2

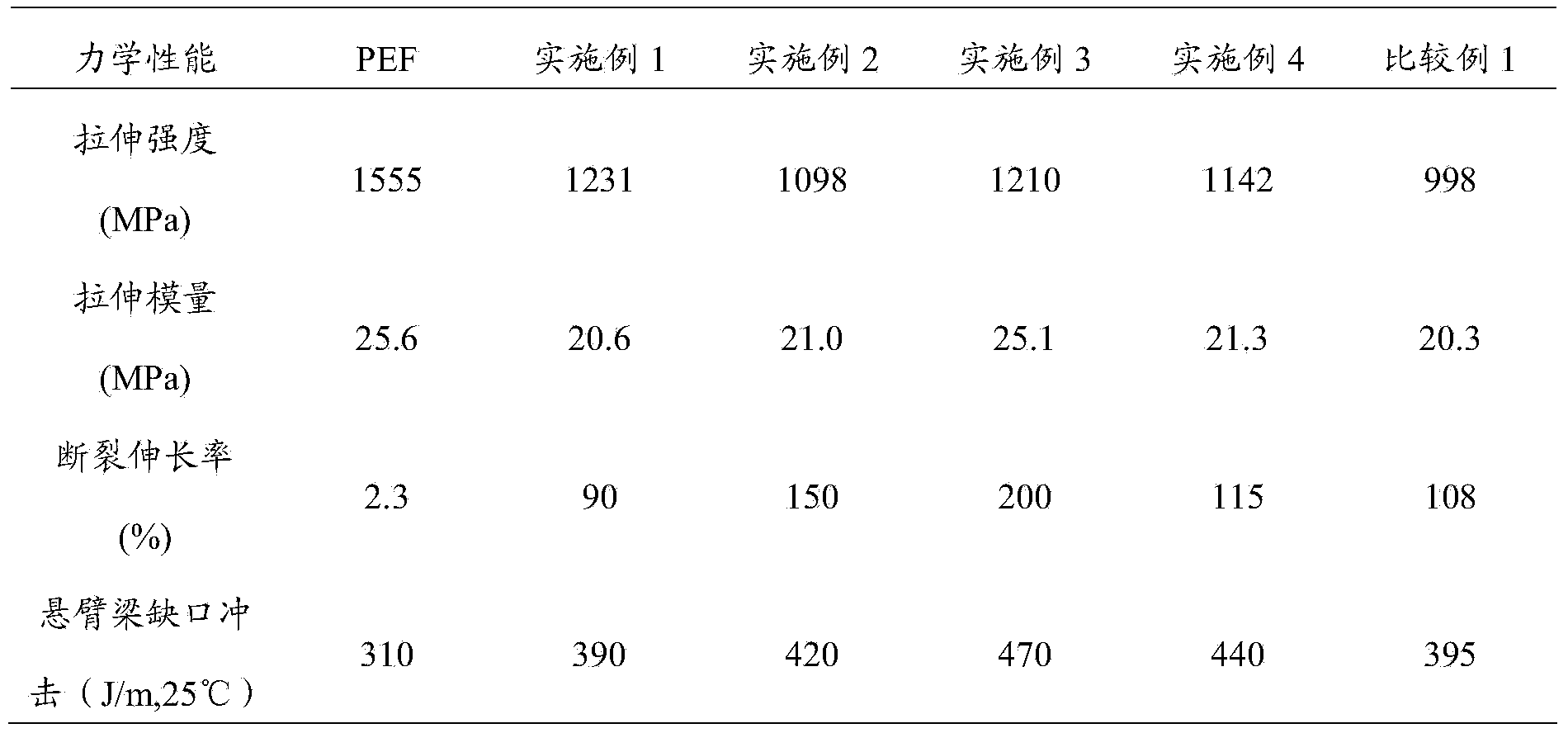

[0088] 100 parts by weight of reduced viscosity is 0.98dL / g polyethylene 2,5-furandicarboxylate, 20 parts by weight of polybutylene succinate and the auxiliary compound obtained in embodiment 1 of 5 parts by weight The agent is mixed in a high-speed mixer for 10 to 15 minutes, and then added to a twin-screw extruder with a rotation speed of 100 rpm and an extrusion temperature of 220°C, fully plasticized, melted, extruded, drawn, and pelletized to obtain a polymer Ethylene glycol 2,5-furandicarboxylate composite.

[0089] The mechanical properties of the polyethylene 2,5-furandicarboxylate composite material obtained in Example 2 were tested, and the results obtained are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reduced viscosity | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com