Environment-friendly flame-retardant polyurethane emulsion and preparation method thereof

A polyurethane emulsion and flame-retardant technology, which is applied in the field of environment-friendly flame-retardant polyurethane emulsion and its preparation, can solve the problems such as few reports of environment-friendly flame-retardant polyurethane emulsion, and achieve the effect of easy control, convenient operation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

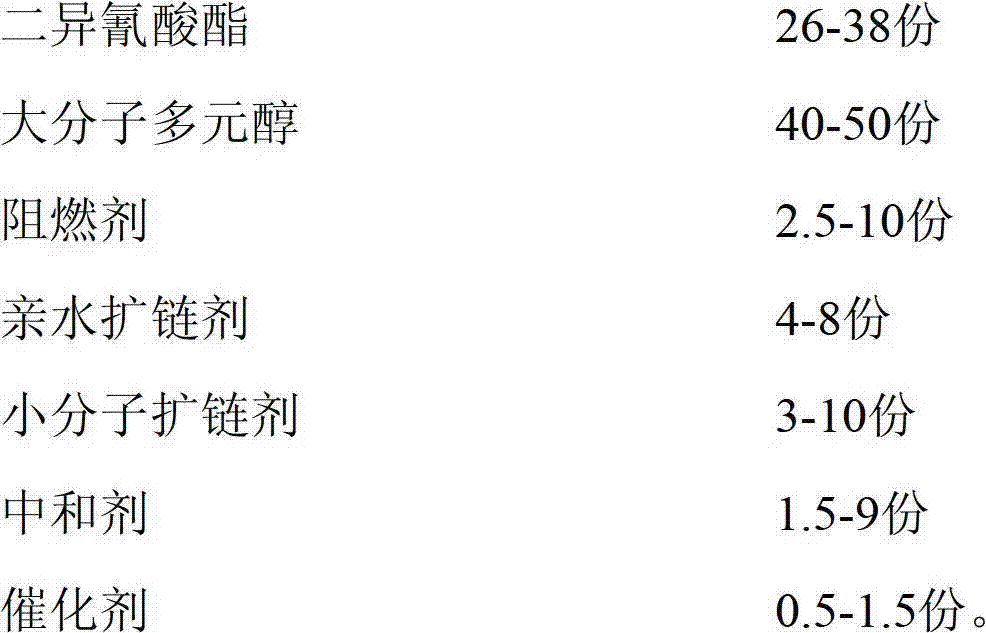

[0027] 1. The formula of environmentally friendly flame-retardant polyurethane emulsion is as follows:

[0028]

[0029] 2. The preparation method is as follows:

[0030] The polycarbonate diol was dehydrated in a vacuum oven for 24 hours before the experiment. Add IPDI, PCDL and DOPO-HQ into a dry four-necked flask with a stirrer and a condenser, raise the temperature of the system to 80°C, add dibutyltin dilaurate dropwise, and react for 3 hours to obtain prepolymer I; prepolymer Ⅰ Cool down to 65°C, add 50g of acetone, dimethylolpropionic acid and 1,4-butanediol (dissolved in DMF), react at 70°C until the content of isocyanate no longer changes to obtain prepolymer II, then Add triethylamine dropwise to prepolymer II, neutralize at room temperature for 30 minutes, then add 336.5 g of deionized water at 0°C, stir to emulsify and obtain a white bluish emulsion, and distill under reduced pressure to remove the solvent to obtain the product . In the formula of the present...

Embodiment 2

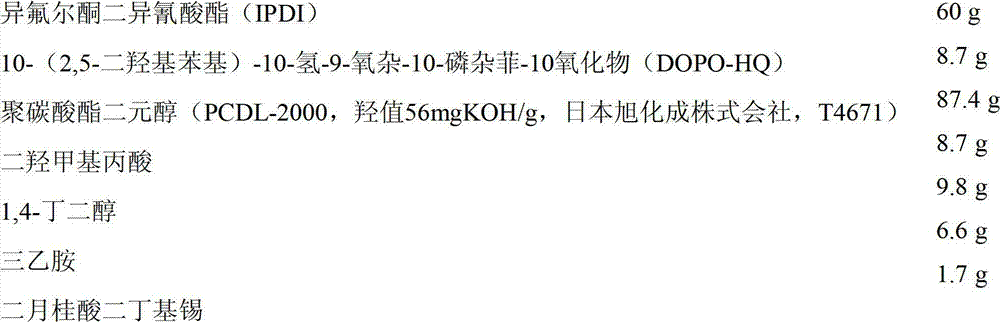

[0032] 1. The formula of environmentally friendly flame-retardant polyurethane emulsion is as follows:

[0033]

[0034]

[0035] 2. The preparation method is as follows:

[0036] The preparation method of this example is the same as that of Example 1, except that -NCO / -OH (molar ratio) is 1.2:1, the neutralization rate is 100%, the solid content is 35%, and the flame retardant content is 4.8%. The environment-friendly flame-retardant polyurethane emulsion prepared by the invention is translucent and non-agglomerated emulsion. Pour the prepared water-based polyurethane emulsion onto a glass template, place it horizontally, dry it at room temperature to form a film, then put it in an oven and dry it at 50°C for 3-4 days, take it out and put it in a desiccator for later use. The performance measurement results are shown in Table 1.

Embodiment 3

[0038] 1. The formula of environmentally friendly flame-retardant polyurethane emulsion is as follows:

[0039]

[0040] 2. The preparation method is as follows:

[0041] The preparation method of this example is the same as that of Example 1, except that -NCO / -OH (molar ratio) is 1.3:1, the neutralization rate is 100%, the solid content is 35%, and the flame retardant content is 4.8%. The environment-friendly flame-retardant polyurethane emulsion prepared by the invention is translucent and non-agglomerated emulsion. Pour the prepared water-based polyurethane emulsion onto a glass template, place it horizontally, dry it at room temperature to form a film, then put it in an oven and dry it at 50°C for 3-4 days, take it out and put it in a desiccator for later use. The performance measurement results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com