Manufacture process for eucalyptus core plate

A production process and technology of eucalyptus wood, applied in the field of production process of eucalyptus core board, can solve the problems of anti-deformation, anti-corrosion and anti-insect bite, and achieve the effect of good nail holding force, energy saving and smooth board surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

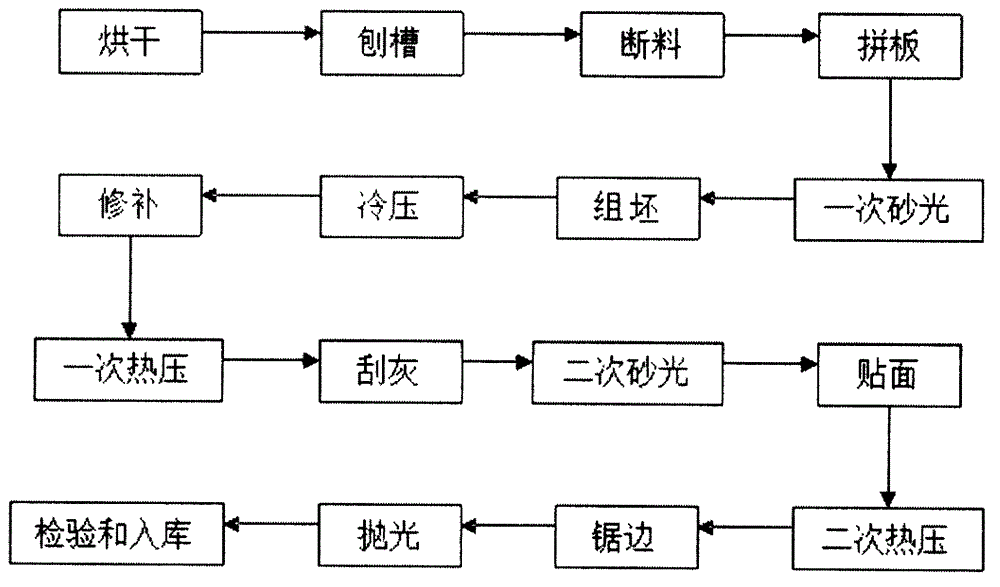

[0038] A kind of production technology of eucalyptus core board, wherein, this production technology comprises the following steps:

[0039] (1) Drying: sun-dry the eucalyptus wood core strip for 5 days, or put it into a drying kiln for baking, and control the moisture content of the eucalyptus wood core strip after sun-drying or baking at 10 degrees;

[0040] (2) Grooving: The eucalyptus core strips after sun exposure or baking treatment are drawn into small square strips by a stripping machine, which can be drawn into 10mm small square strips, and then planed into double-sided grooves by a double-sided planer Small square strips, the requirements for the small square strips after grooving are: 10mm long, 3mm wide, and 2mm high concave-convex double-sided grooves;

[0041] (3) Material cutting: cut the eucalyptus core square strips after the grooving into required specifications with a saw table according to the required size specifications, and then coat the specifications m...

Embodiment 2

[0065] A kind of production technology of eucalyptus core board, wherein, this production technology comprises the following steps:

[0066] (1) Drying: Sun-dry the eucalyptus core strips for 8 days, or put them into a drying kiln for baking, and control the moisture content of the eucalyptus wood core strips after sun-drying or baking at 15 degrees;

[0067] (2) Grooving: The eucalyptus core strips after sun exposure or baking treatment are drawn into small square strips by a stripping machine, which can be drawn into 13mm small square strips, and then planed into double-sided grooves by a double-sided planer Small square strips, the requirements for the small square strips after grooving are: a concave-convex double-sided groove with a length of 13mm, a width of 4mm, and a height of 2.5mm;

[0068] (3) Material cutting: cut the eucalyptus core square strips after the grooving into required specifications with a saw table according to the required size specifications, and the...

Embodiment 3

[0092] A kind of production technology of eucalyptus core board, wherein, this production technology comprises the following steps:

[0093] (1) Drying: Sun-dry the eucalyptus core strips for 10 days, or put them into a drying kiln for baking, and control the moisture content of the eucalyptus wood core strips after sun-drying or baking at 17 degrees;

[0094] (2) Grooving: The eucalyptus core strips after sun exposure or baking treatment are drawn into small square strips by a stripping machine, which can be drawn into 15mm small square strips, and then planed into double-sided grooves by a double-sided planer. Small square strips, the requirements for the small square strips after grooving are: 15mm long, 5mm wide, and 3mm high concave-convex double-sided grooves;

[0095] (3) Material cutting: cut the eucalyptus core square strips after the grooving into required specifications with a saw table according to the required size specifications, and then coat the specifications ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com