Hollow wooden integration column

An integrated column and wood technology, applied in the direction of hollow objects, wood processing appliances, household components, etc., can solve problems such as labor-intensive, inability to be directly applied, no data reporting and physical appearance yet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

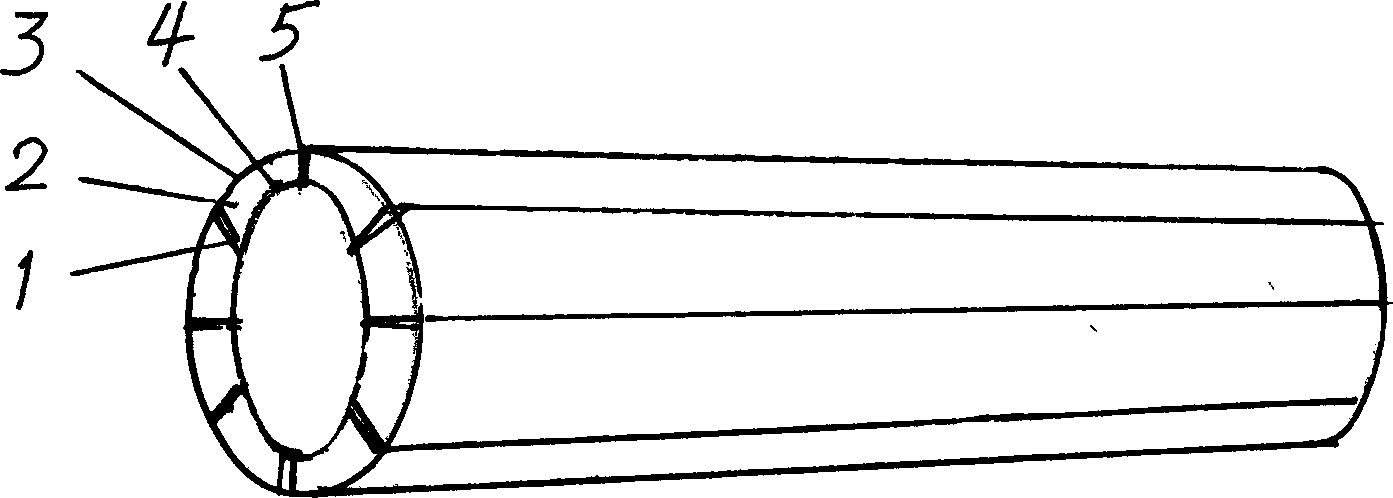

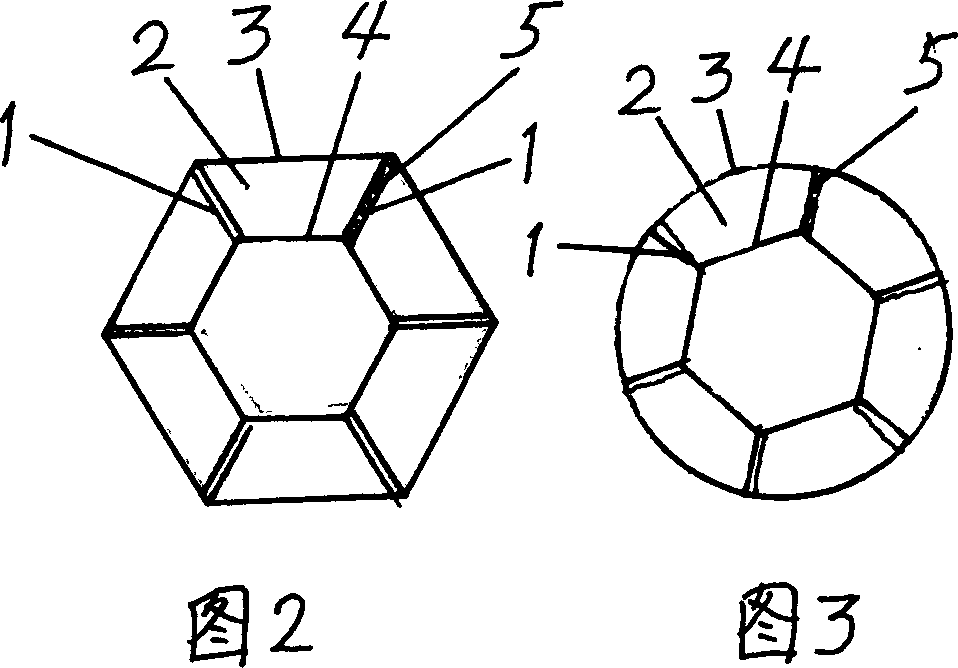

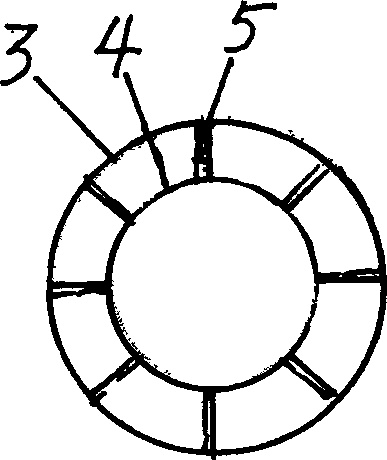

[0011] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings: the hollow wood integrated column is composed of multiple (at least 3) long wooden strips (hereinafter referred to as trapezoidal strips or similar trapezoidal strips) with trapezoidal or trapezoidal cross sections. ) is glued together, as shown in Figure 2, it is glued with trapezoidal strips, figure 1 , 3, and 4 show that the trapezoidal strips are glued together, the surface of the lower bottom 3 forms the outer wall of the column, the surface of the upper bottom 4 forms the inner wall of the column, and the two sides of the trapezoidal or similar trapezoidal strips (i.e. the waist 1 of the two trapezoids) Surface) sizing, just produced adhesive layer 5 after gluing, and this adhesive layer 5 should be tight, is the laminar structure on the microcosmic concept, for explaining the problem, on the accompanying drawing, show with wide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com