Polypropylene carbonate modified composite material and preparation method thereof

A polypropylene carbonate and composite material technology, applied in the field of polymer materials, can solve the problems of limiting PPC processing temperature and application range, random chain breaking and degradation, etc., and achieve widening processing temperature range, low price, and high preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

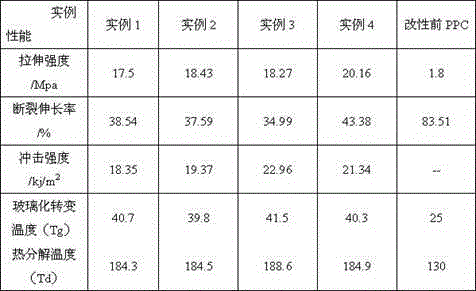

Examples

Embodiment 1

[0024] A polypropylene carbonate modified composite material, consisting of the following components in parts by weight: 70 parts of polypropylene carbonate, 20 parts of polypropylene, 10 parts of PP-g-AA copolymer, 0.2 part of antioxidant 1010 , 0.2 parts of antioxidant 168, 0.15 parts of UV944 and 0.8 parts of additives are blended.

[0025] The above-mentioned polypropylene carbonate modified composite material is specifically prepared by the following steps:

[0026] Step 1, mixing 70 parts of polypropylene carbonate, 20 parts of polypropylene and 10 parts of PP-g-AA copolymer to obtain mixed material I;

[0027] Step 2, add 0.2 parts of antioxidant 1010, 0.2 parts of antioxidant 168, 0.15 parts of UV944 and 0.8 parts of additives to the mixed material I in step 1, and mix well to obtain mixed material II;

[0028] Step 3, add the mixed material II of step 2 into the twin-screw extruder, and the twin-screw extruder extrudes and granulates to obtain the required composite ...

Embodiment 2

[0030] A polypropylene carbonate modified composite material, consisting of the following components in parts by weight: 75 parts of polypropylene carbonate, 15 parts of polypropylene, 5 parts of PP-g-AA copolymer, 0.1 part of antioxidant 1098 , 0.1 part of antioxidant 626, 0.2 part of UV324 and 0.3 part of additives are blended.

[0031] The above-mentioned polypropylene carbonate modified composite material is specifically prepared by the following steps:

[0032] Step 1, 75 parts of polypropylene carbonate, 15 parts of polypropylene and 5 parts of PP-g-AA copolymer are mixed to obtain mixed material I;

[0033] Step 2, add 0.1 part of antioxidant 1098, 0.1 part of antioxidant 626, 0.2 part of UV324 and 0.3 part of additives to the mixed material I in step 1, and stir to obtain the mixed material II;

[0034] Step 3, add the mixed material II of step 2 into the twin-screw extruder, and the twin-screw extruder extrudes and granulates to obtain the required composite material...

Embodiment 3

[0036] A polypropylene carbonate modified composite material, consisting of the following components in parts by weight: 60 parts of polypropylene carbonate, 30 parts of polypropylene, 10 parts of PP-g-AA copolymer, 0.2 part of antioxidant 1076 , 0.2 parts of antioxidant 618, 0.3 parts of UV-P and 0.5 parts of additives are blended.

[0037] The above-mentioned polypropylene carbonate modified composite material is specifically prepared by the following steps:

[0038] Step 1, 60 parts of polypropylene carbonate, 30 parts of polypropylene and 10 parts of PP-g-AA copolymer are mixed to obtain mixed material I;

[0039] Step 2, add 0.2 parts of antioxidant 1076, 0.2 parts of antioxidant 618, 0.3 parts of UV-P and 0.5 parts of additives to the mixed material I in step 1, and mix well to obtain mixed material II;

[0040] Step 3, add the mixed material II of step 2 into the twin-screw extruder, and the twin-screw extruder extrudes and granulates to obtain the required composite m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com