Steel-based multifunctional ceramic composite coating and preparation method thereof

A ceramic composite and multi-functional technology, applied in the direction of ceramic layered products, coatings, chemical instruments and methods, etc., can solve the problems of large difference in thermal and physical properties, poor bonding performance, etc., to achieve electrical insulation performance, maintain integrity, The effect of prolonging service time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

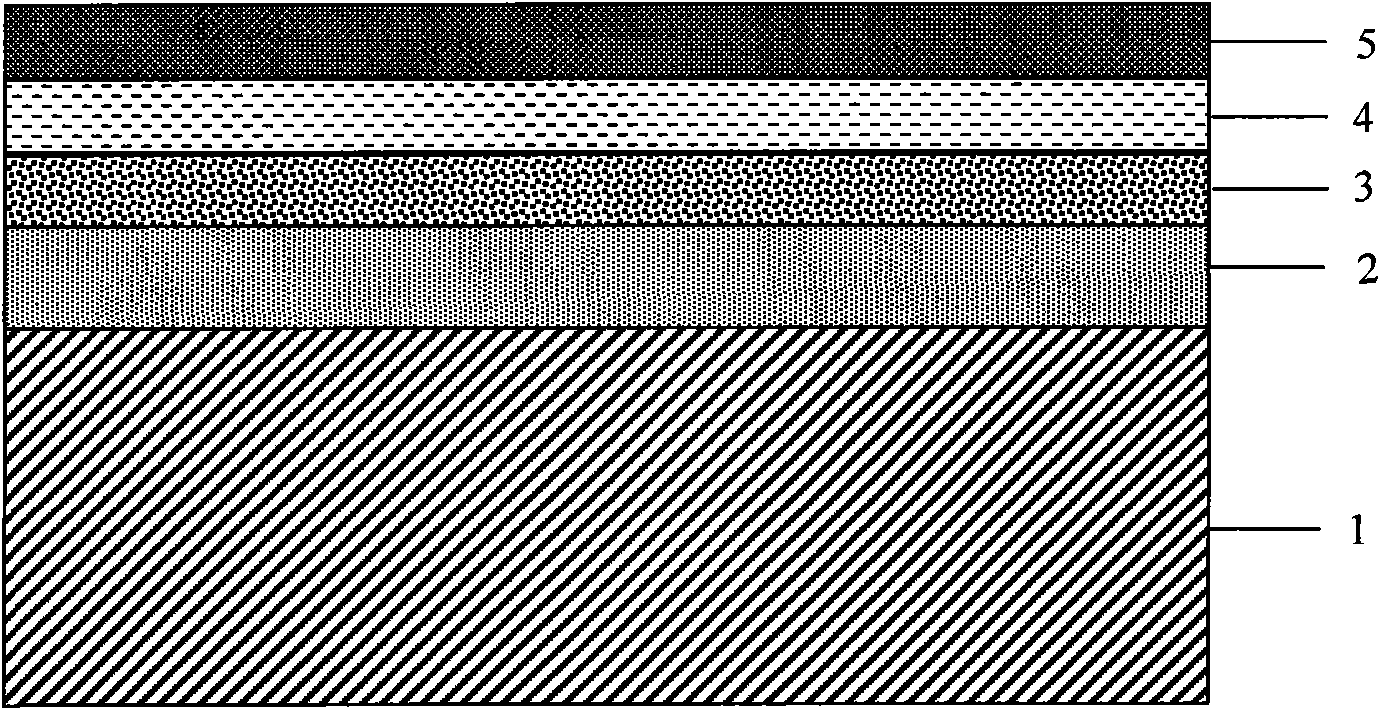

[0012] In Fig. 1, 1 is the base alloy steel, 2 is the iron-aluminum alloy layer, 3 is the alumina coating, 4 is the silicon dioxide coating, and 5 is the silicon carbide coating.

[0013] Preparation method of steel-based multifunctional ceramic composite coating:

[0014] 1. Using a vacuum plasma spraying process to prepare an iron-aluminum alloy layer 2 with a thickness of 50-150 μm on the surface of the base alloy steel 1 .

[0015] 2. Prepare an aluminum oxide coating 3 with a thickness of 20-100 μm on the iron-aluminum alloy layer by using a vacuum plasma spraying process.

[0016] 3. Prepare a silicon dioxide coating 4 with a thickness of 10-50 μm on the aluminum oxide coating 3 by using a vacuum plasma spraying process.

[0017] 4. Prepare a silicon carbide coating 5 with a thickness of 20-100 μm on the silica glass layer 4 by using a vacuum plasma spraying process.

[0018] 5. The composite coating is densified as a whole by hot isostatic pressing to obtain an alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com