Solid wood sawed composite board and machining process

A technology of composite boards and solid wood boards, which is applied in the direction of wood processing equipment, the joining of wooden veneers, manufacturing tools, etc., can solve environmental pollution and other problems, and achieve the effects of flexible specifications and sizes, less glue usage, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

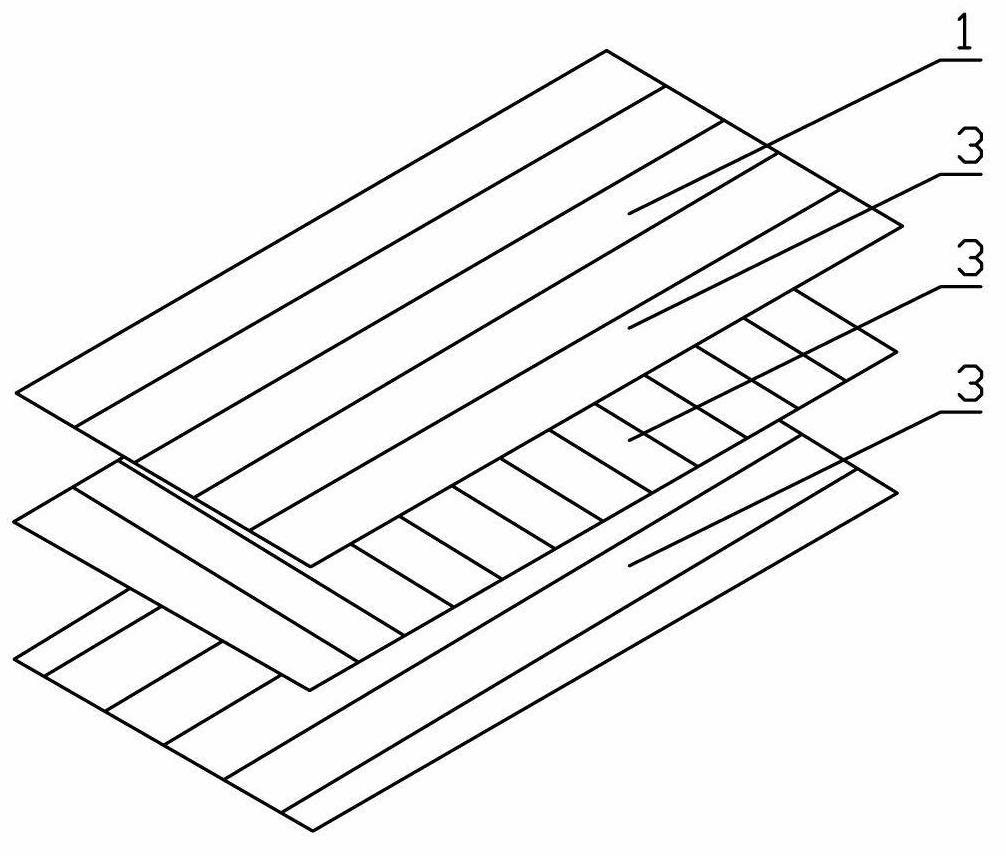

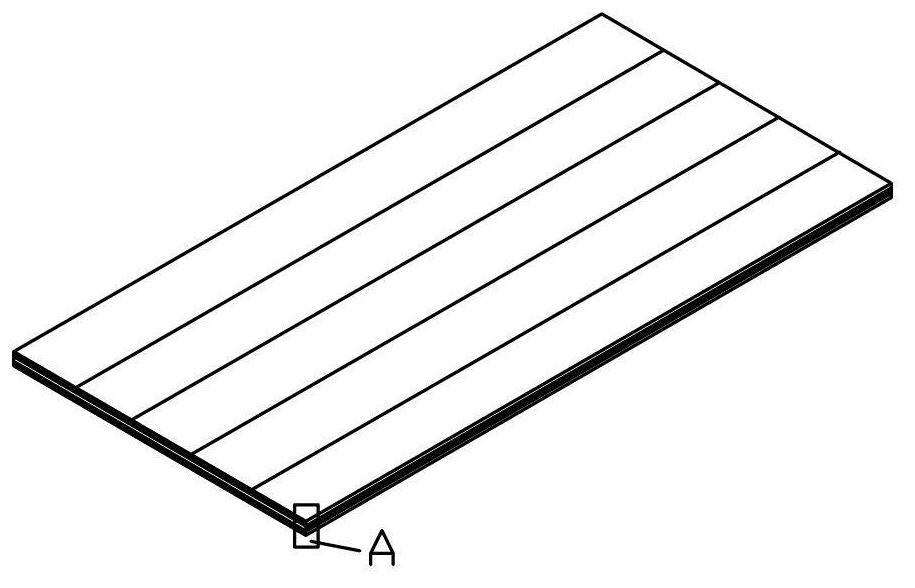

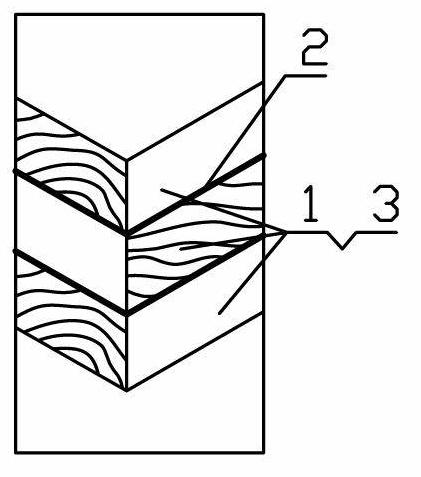

[0040] The specific embodiment of the present invention is shown in accompanying drawing, it is characterized in that described solid wood sawn composite board is made up of solid wood veneer 1 and adhesive 2 sawn after multi-layer drying; Aligned and tiled, solid wood veneers 1 are bonded by adhesive 2 to form a single-layer solid wood board 3; 3 layers of single-layer solid wood boards 3 are bonded by adhesive 2 and compacted into a multi-layer solid wood saw Cut composite board.

[0041] The fiber direction of the two-layer single-layer solid wood board 3 adjacent to the solid wood sawing composite board is laminated vertically or parallel to the dislocation lamination; the adhesive can use different types of glue according to different needs, such as urea-formaldehyde glue, phenolic glue, Modified melamine glue, etc.

[0042] The thickness of the solid wood veneer 1 is above 2mm.

[0043] The processing technology of solid wood sawing composite board, its technological p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com