Degrading and recovering method of epoxy resin composite material

A technology of epoxy resin and recycling method, applied in the field of epoxy resin, can solve the problems of difficulty in removing, recycling and reusing epoxy resin, strong acid corrosion, low operation safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

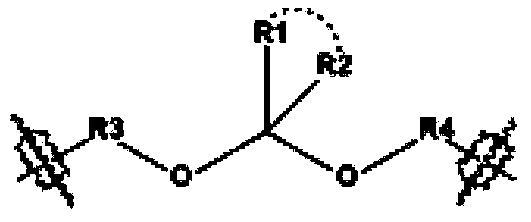

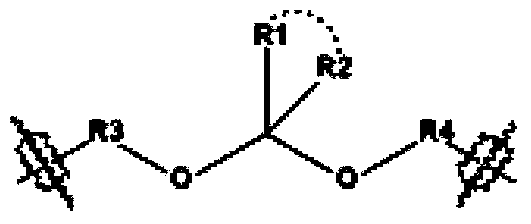

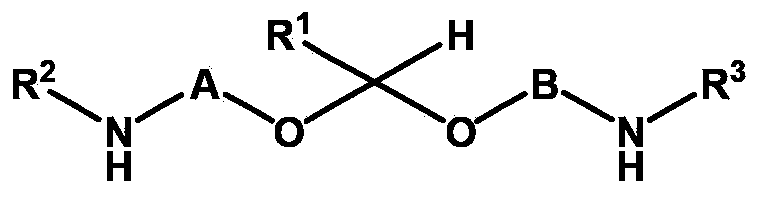

Image

Examples

Embodiment 1

[0109] Embodiment 1: the preparation of curing agent A

[0110]

[0111] 1000 grams of N-hydroxyethylphthalimide, 157 grams of paraformaldehyde, 6.8 grams of anhydrous p-toluenesulfonic acid, and 1.5 liters of toluene were mixed at room temperature, DEAN-STARK was refluxed to separate water, and reacted for 20 hours. Finish, lower to room temperature, add 2 liters of petroleum ether with a boiling range of 60-90, filter, wash the solid with 1 liter of petroleum ether with a boiling range of 60-90 ° C, and dry the solid to obtain 950 grams of crude product, add 3.4 liters of 20% NaOH solution, Heat to reflux for 10 hours, cool, add chloroform / isopropanol for extraction, separate layers, dry the organic phase with anhydrous sodium sulfate, and collect fractions with a boiling range of 71-72°C under vacuum at 70 Pa to obtain 200 grams of colorless liquid a. 1H NMR (CDCl3, 400MHz): 4.74(s, 2H), 3.59(t, J=5.2Hz, 4H), 2.89(t, J=5.2Hz, 4H).

Embodiment 2

[0112] Embodiment 2: the preparation of curing agent B

[0113]

[0114] 1000 grams of N-hydroxyethylphthalimide, 280 grams of 2,2-dimethoxypropane, 8 grams of anhydrous p-toluenesulfonic acid, 1.5 liters of toluene were mixed at room temperature, DEAN-STARK was refluxed to separate water , reacted for 20 hours, the reaction was completed, lowered to room temperature, added 2 liters of petroleum ether with a boiling range of 60-90°C, filtered, washed the solid with 1 liter of petroleum ether with a boiling range of 60-90°C, and dried the solid to obtain 900 grams of crude product, adding 460 grams of 80% hydrazine hydrate and 600 milliliters of ethanol were heated and refluxed for 10 hours, cooled, filtered, ethanol and dichloromethane washed the solids respectively, and the organic phase was dried with anhydrous sodium sulfate and collected by distillation under reduced pressure at 80Pa under vacuum conditions, 61-64 °C boiling range fraction to obtain 200 g of colorless l...

Embodiment 3

[0115] Embodiment 3: Preparation of degradable carbon fiber composite material

[0116] At room temperature, mix 20 grams of curing agent A with 112 grams of bisphenol A epoxy resin 828 (epoxy equivalent 185-192) and stir evenly, penetrate into three layers of carbon fiber cloth (3K) by hand lay-up method, and heat at 80 degrees for 2 hours. Heat at 125 degrees for 1 hour until fully cured, and prepare a carbon fiber composite material sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com