Lithium-titanium composite metal oxide micro/nano material and its preparation method and application

A composite oxide and lithium-titanium composite technology, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc. Degradation research and other issues, to achieve the effect of easy large-scale preparation, strong oxidation performance, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The method for preparing the above-mentioned lithium-titanium composite metal oxide micro / nano material provided by the present invention, its main steps are:

[0037] 1) Dissolve the lithium-containing compound in a corresponding amount of aqueous solution, add a certain amount of hydrogen peroxide at the same time, and after stirring evenly, slowly add the titanium-containing compound into the solution while stirring continuously. After the precipitate is dissolved and the solution is transparent, it is transferred to a hydrothermal reaction kettle to react for a period of time. After the solution is cooled to room temperature, the precipitate is collected; the precipitate is washed with distilled water and centrifuged, and dried in an oven to obtain a lithium-titanium composite metal oxide micro / nano material precursor;

[0038] In step 1): the molar ratio of lithium and titanium is 1-10:1-10. The aqueous solution containing lithium ions is one of lithium carbonate,...

Embodiment 1

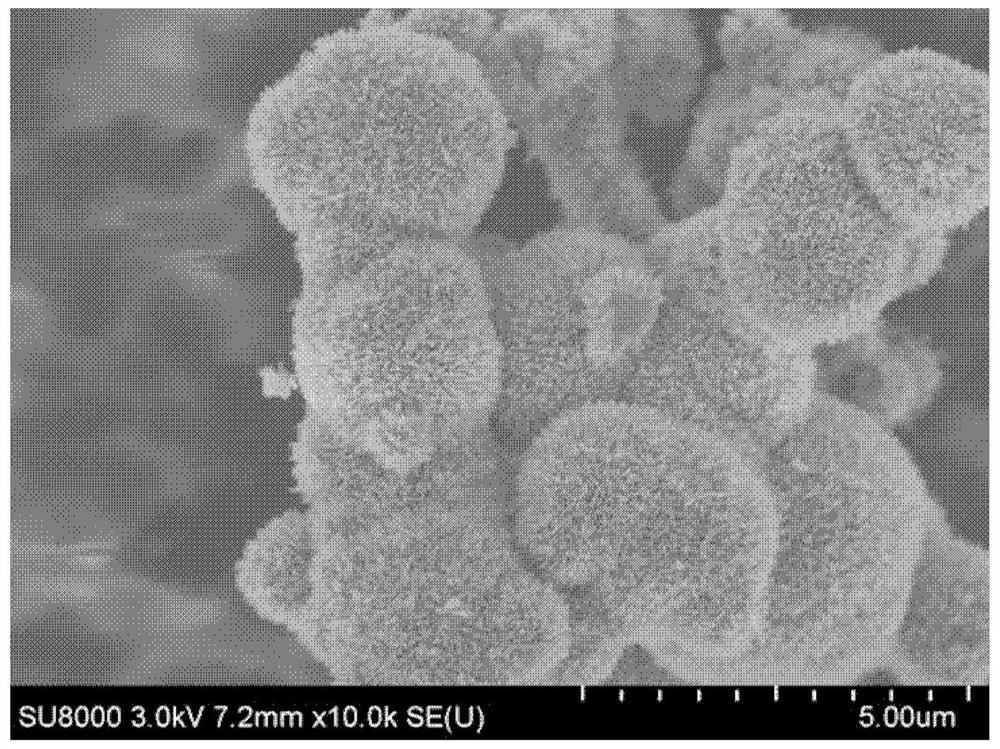

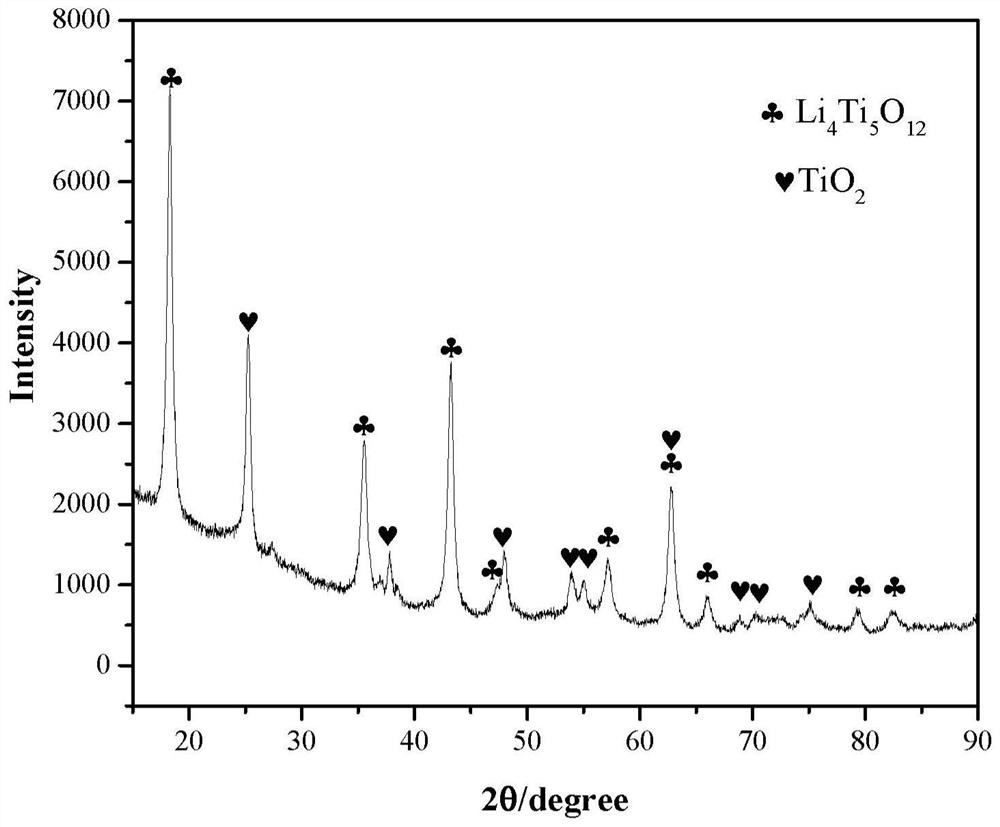

[0045] Take LiOH·H 2 O 0.336g, hydrogen peroxide 1mL and distilled water 20mL were placed in a 100mL beaker, and stirred evenly at room temperature. Subsequently, 0.681 mL of tetrabutyl titanate was slowly added to the above aqueous solution, stirred by electromagnetic at room temperature to become a transparent liquid, and transferred to a 50 mL stainless steel reaction kettle. The reaction kettle was placed in a muffle furnace and reacted at 130°C for 12h. After the reaction was completed, it was cooled to room temperature, and the white precipitate was collected. The precipitate is washed and dried at 80° C. for several hours to obtain the precursor of the lithium-titanium composite metal oxide micro / nano material. The precursor was burned in an air atmosphere at 500 °C for 6 hours in a tube furnace to obtain the target product Li 4 TiO x , its SEM and XRD characterization results are as follows Figure 1A , Figure 1B and Figure 1C shown. Figure 1A , Figure 1B Th...

Embodiment 2

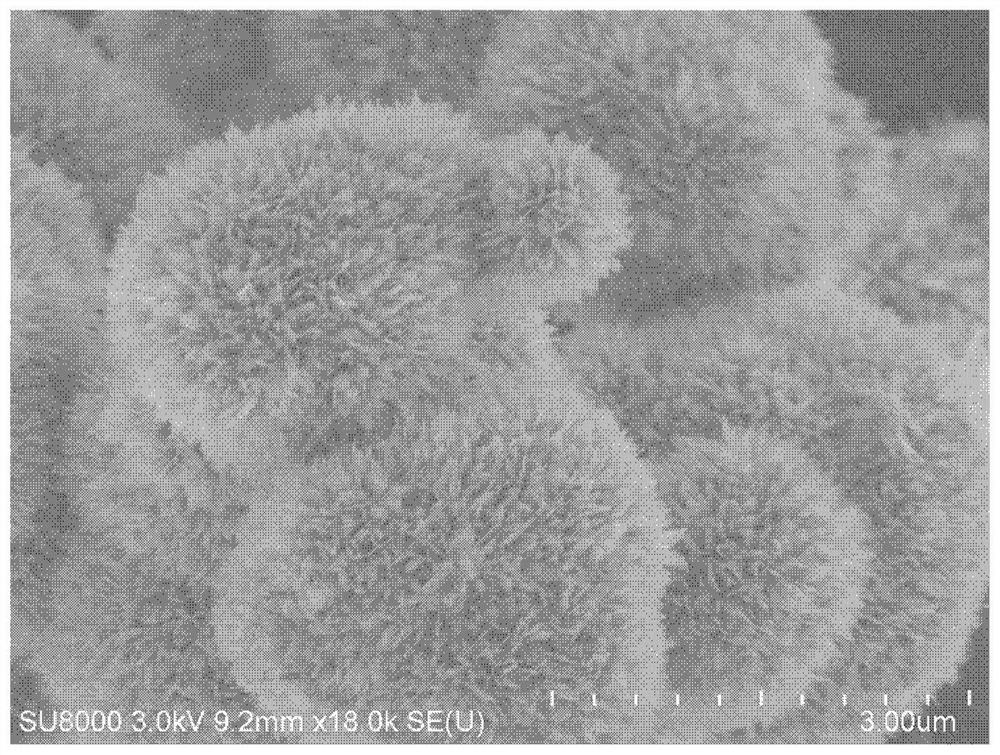

[0047] Take LiOH·H 2 O 0.168g, hydrogen peroxide 1mL and distilled water 20mL were placed in a 100mL beaker, and stirred evenly at room temperature. Subsequently, 0.681 mL of tetrabutyl titanate was slowly added to the above aqueous solution, stirred by electromagnetic at room temperature to become a transparent liquid, and transferred to a 50 mL stainless steel reaction kettle. The reaction kettle was placed in a muffle furnace and reacted at 130°C for 12h. After the reaction was completed, it was cooled to room temperature, and the white precipitate was collected. The precipitate is washed and dried at 80° C. for several hours to obtain the precursor of the lithium-titanium composite metal oxide micro / nano material. The precursor was burned in an air atmosphere at 500 °C for 6 hours in a tube furnace to obtain the target product Li 2 TiO x , its SEM and XRD characterization results are as follows Figure 2A , Figure 2B and Figure 2C shown. Figure 2A , Figure 2B ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com