Preparation method and application of nitrogen-doped reduced graphene oxide-supported cdte/cds heterojunction composite photocatalyst

A nitrogen doping, graphene technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high energy consumption, complex operation, harsh synthesis conditions, etc., and achieve environmental protection treatment technology. , Efficient processing technology, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

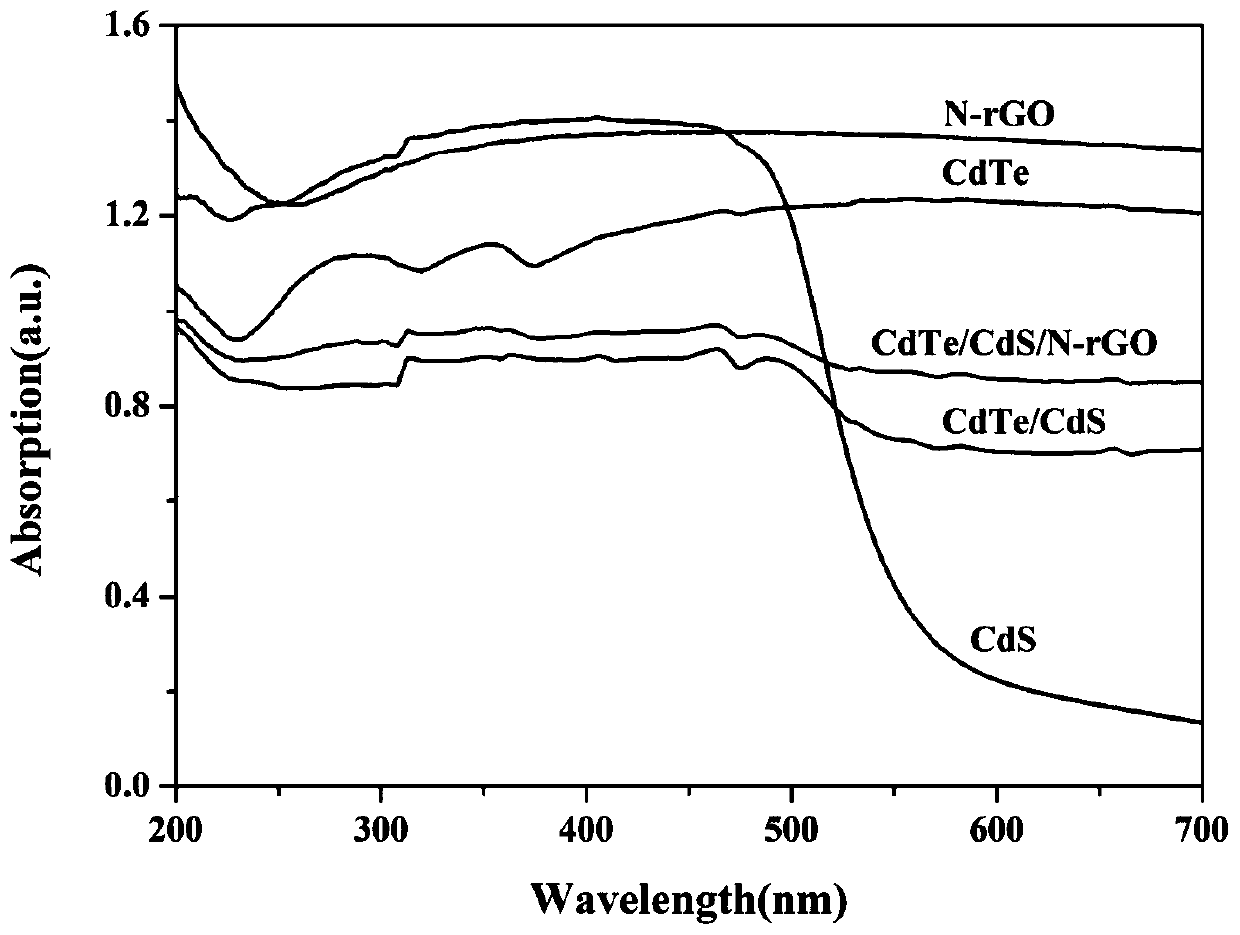

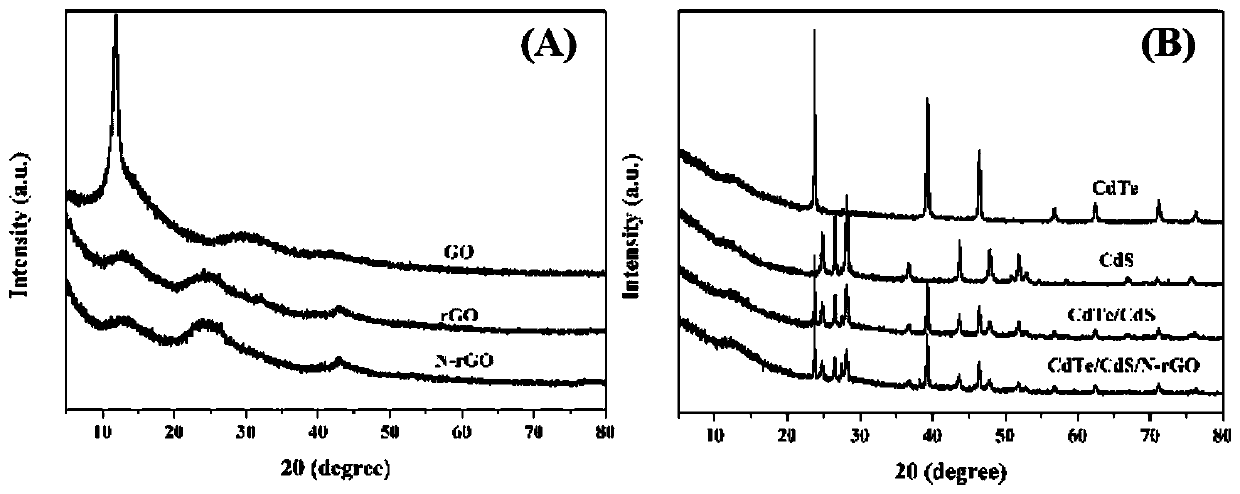

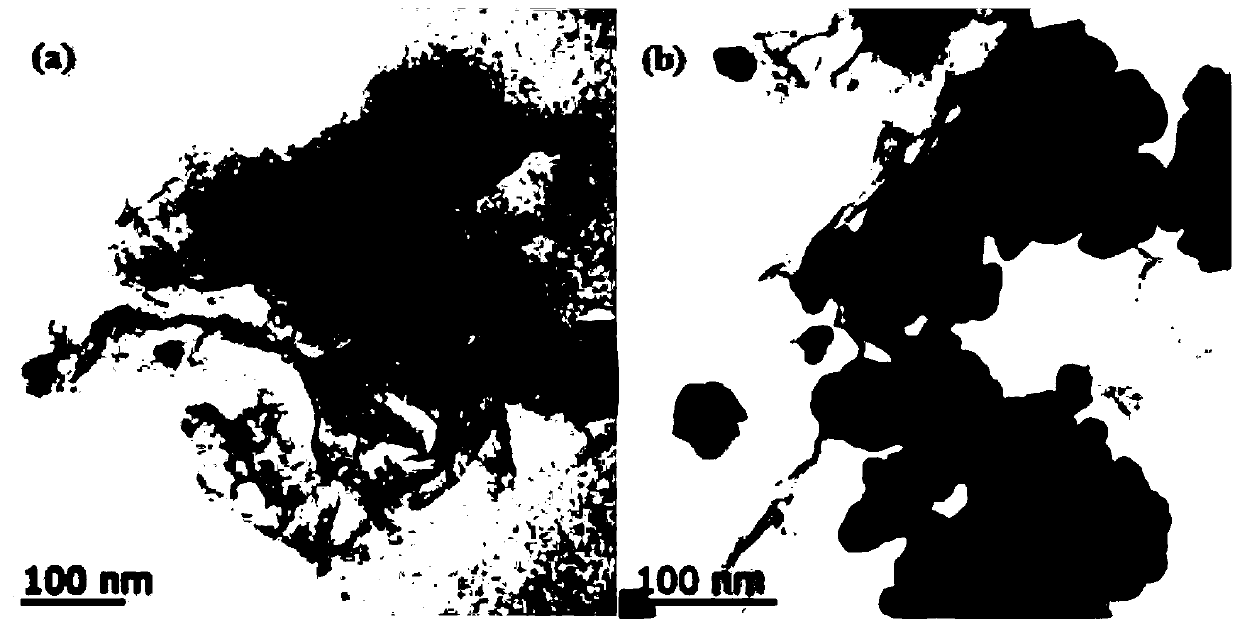

[0054] (1) Nitrogen-doped reduced graphene oxide (N-rGO):

[0055] Graphene oxide (GO) powder was synthesized by the modified Hummer method, 0.3g GO powder was added into 150mL deionized water, and ultrasonically dispersed. Add 2mL ammonia water and sonicate. Then 1 mL of hydrazine hydrate was added, magnetically stirred at 100 °C for 24 h after ultrasonication, centrifuged, washed with deionized water several times, and dried in an oven at 60 °C to obtain N-rGO.

[0056] (2) Preparation of CdTe nanoparticles:

[0057] Weigh 6mmol cadmium chloride (CdCl 2 2.5H 2 0), join in the reactor core of 50mL, add 20mL deionized water, sonicate until completely dissolved, then add 10mL ammonia water, 0.4g tartaric acid, 4mmol sodium tellurite, 4mL hydrazine hydrate, ultrasonic treatment for half an hour, pack The kettle was placed in an oven at 180°C for 5 hours, cooled to room temperature, centrifuged, washed several times with deionized water and absolute ethanol, and dried in an o...

Embodiment 2

[0062] (1) Nitrogen-doped reduced graphene oxide (N-rGO):

[0063] Graphene oxide (GO) powder was synthesized by the modified Hummer method, 0.3g GO powder was added into 150mL deionized water, and ultrasonically dispersed. Add 2mL ammonia water and sonicate. Then 1 mL of hydrazine hydrate was added, magnetically stirred at 100 °C for 24 h after ultrasonication, centrifuged, washed with deionized water several times, and dried in an oven at 60 °C to obtain N-rGO.

[0064] (2) Preparation of CdTe nanoparticles:

[0065] Weigh 6mmol cadmium chloride (CdCl 2 2.5H 2 0), join in the reactor core of 50mL, add 20mL deionized water, sonicate until completely dissolved, then add 10mL ammonia water, 0.4g tartaric acid, 4mmol sodium tellurite, 4mL hydrazine hydrate, ultrasonic treatment for half an hour, pack The kettle was placed in an oven at 180°C for 5 hours, cooled to room temperature, centrifuged, washed several times with deionized water and absolute ethanol, and dried in an o...

Embodiment 3

[0070] (1) Nitrogen-doped reduced graphene oxide (N-rGO):

[0071] Graphene oxide (GO) powder was synthesized by the modified Hummer method, 0.3g GO powder was added into 150mL deionized water, and ultrasonically dispersed. Add 2mL ammonia water and sonicate. Then 1 mL of hydrazine hydrate was added, magnetically stirred at 100 °C for 24 h after ultrasonication, centrifuged, washed with deionized water several times, and dried in an oven at 60 °C to obtain N-rGO.

[0072] (2) Preparation of CdTe nanoparticle photocatalyst:

[0073] Weigh 6mmol cadmium chloride (CdCl 2 2.5H 2 0), join in the reactor core of 50mL, add 20mL deionized water, sonicate until completely dissolved, then add 10mL ammonia water, 0.4g tartaric acid, 4mmol sodium tellurite, 4mL hydrazine hydrate, ultrasonic treatment for half an hour, pack The kettle was placed in an oven at 180°C for 5 hours, cooled to room temperature, centrifuged, washed several times with deionized water and absolute ethanol, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com