Epoxy resin composite wave-absorbing material and preparation method thereof

A composite wave-absorbing material and epoxy resin technology, applied in the field of electromagnetic wave-absorbing materials, can solve the problems of narrow wave-absorbing frequency band and low wave-absorbing efficiency, and achieve the goal of increasing absorption value, improving wave-transmitting ability, and broadening wave-absorbing frequency band Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

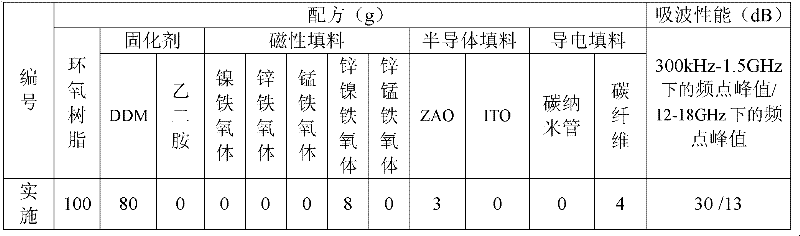

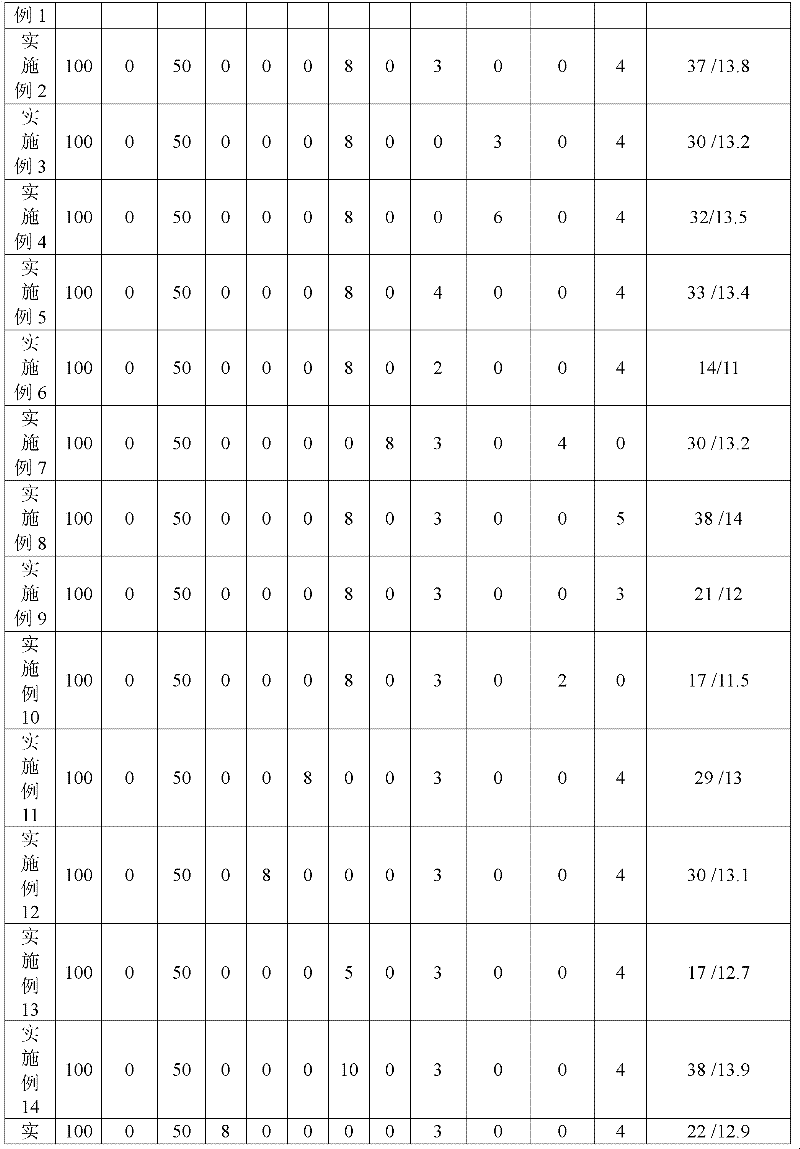

Embodiment 1~19

[0032] Examples 1-19 The preparation method of the composite wave-absorbing material is as follows:

[0033] (1) Put epoxy resin E-51 into a three-necked flask, heat and stir in a constant temperature water bath at 60°C, and after the epoxy resin E-51 becomes thinner, add magnetic fillers, conductive fillers and semiconductor fillers into the three-necked flask, Stir in a water bath at 60°C for 10 minutes, and the speed of the mixer is 400 rpm;

[0034] Wherein, the magnetic filler is one or more of nickel ferrite, zinc ferrite, manganese ferrite, zinc-nickel ferrite or zinc-manganese ferrite, and the particle size of the magnetic filler is 3 to 7μm;

[0035] The conductive filler is one or both of carbon fiber or carbon nanotube; the length of carbon fiber is 0.5-6mm, and the outer diameter of carbon nanotube is 5-50nm;

[0036] The semiconductor filler is one or both of aluminum-doped zinc oxide (ZAO) or tin-doped indium oxide (ITO); the particle size of the semiconductor ...

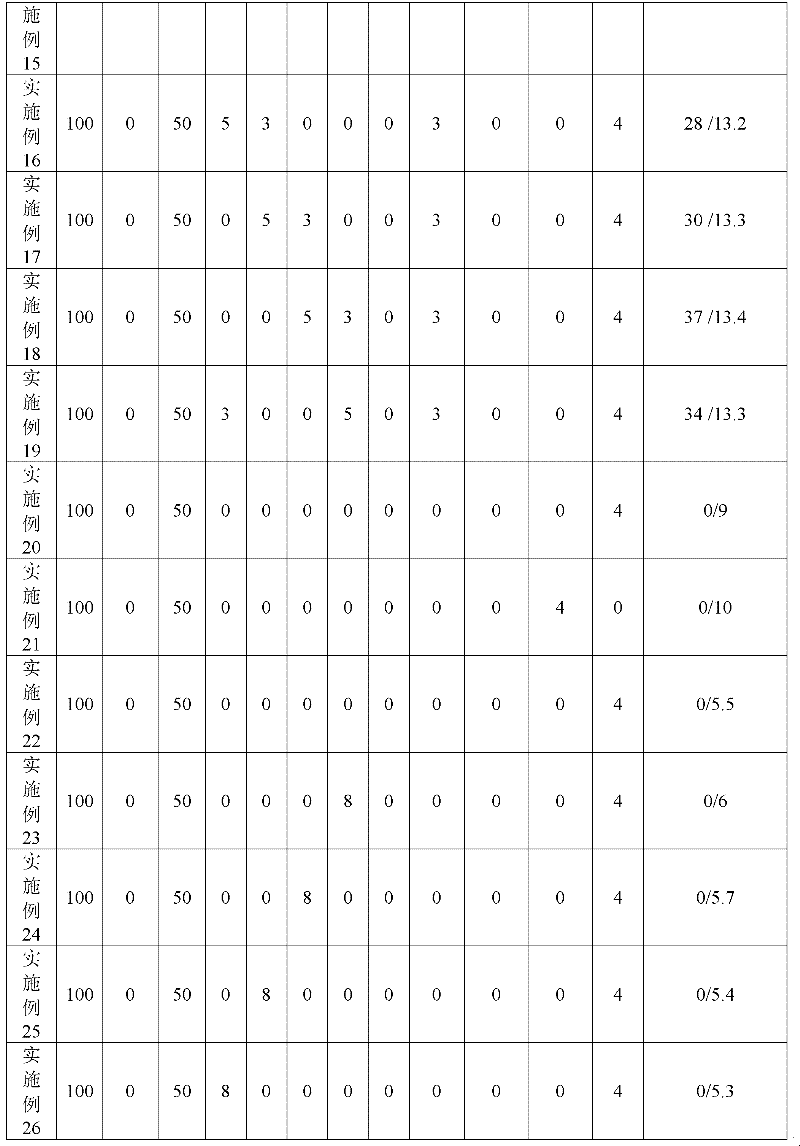

Embodiment 20~27

[0039] Examples 20-27 The preparation method of the composite wave-absorbing material is as follows:

[0040] (1) Put epoxy resin E-51 into a three-necked flask, heat and stir in a constant temperature water bath at 60°C, and after the epoxy resin E-51 becomes thinner, add magnetic fillers and conductive fillers into a three-necked flask, and place in a water bath at 60°C Stir for 10 minutes at a lower speed, and the speed of the mixer is 400 rpm;

[0041] Wherein, the magnetic filler is one or more of nickel ferrite, zinc ferrite, manganese ferrite, zinc-nickel ferrite or zinc-manganese ferrite, and the particle size of the magnetic filler is 3 to 7μm;

[0042] The conductive filler is one or both of carbon fiber or carbon nanotube; the length of carbon fiber is 0.5-6mm, and the outer diameter of carbon nanotube is 5-50nm;

[0043] (2) Put the curing agent into a three-necked flask, add 2 mL of defoamer tributyl phosphate, stir at 500 rpm, stir in a water bath at 60°C for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com