Epoxy resin composite coating solution, and preparation method and application method thereof

A technology of epoxy resin solution and epoxy resin, which is applied in the direction of epoxy resin coatings, coatings, devices for coating liquid on the surface, etc., can solve the problems of less research on the friction properties of composite materials, and achieve good matrix bonding force , low friction coefficient, excellent wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

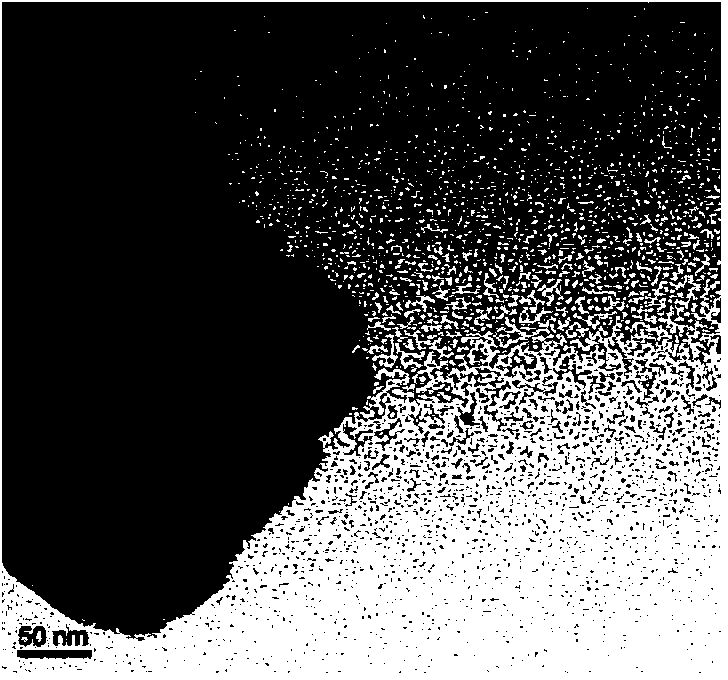

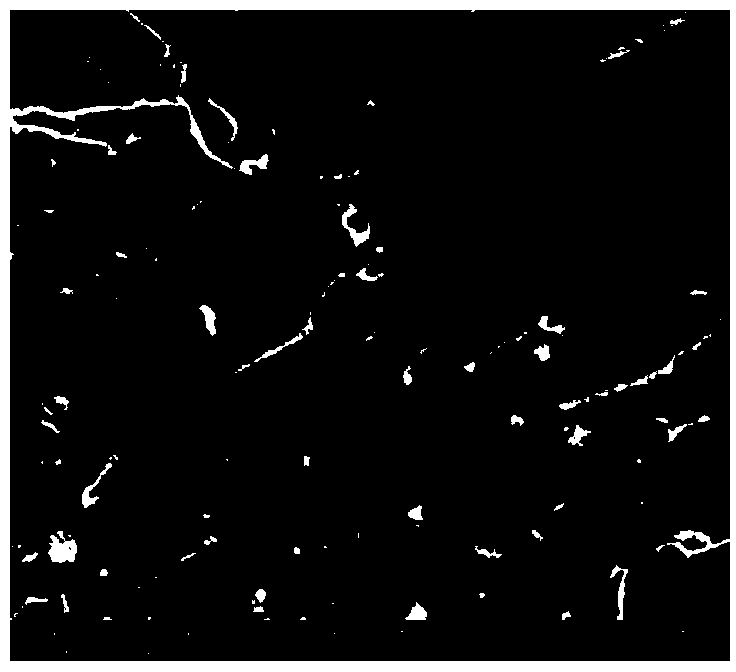

Image

Examples

Embodiment 1

[0045] In this embodiment, the composite coating solution is composed of solvent, epoxy resin E51 and graphene modified by silane coupling agent. Wherein, the solvent is a mixed solvent formed by mixing xylene and n-butanol with a mass ratio of 7:3, and the mass of graphene accounts for 0.25% of the epoxy resin E51 mass.

[0046] The preparation method of the graphene modified by the silane coupling agent is: graphene and silane coupling agent KH550 are added to a mixed solvent whose mass ratio is 1:20 by a certain amount of ethanol and deionized water. , ultrasonically dispersed for 1 hour, and mechanically stirred for 5 hours in a water bath environment at 60°C to couple the silane coupling agent to the graphene surface through a coupling reaction, and then wash with ethanol and deionized water for 3 times to remove the residual silane coupling on the surface agent, and dried at 120°C for 10 hours to obtain silane coupling agent-modified graphene.

[0047] The preparation m...

Embodiment 2

[0051] In this embodiment, the composite coating solution is composed of solvent, epoxy resin E51 and graphene modified by silane coupling agent. Wherein, the solvent is a mixed solvent formed by mixing xylene and n-butanol with a mass ratio of 7:3, and the mass of graphene accounts for 0.5% of the epoxy resin E51 mass.

[0052] The preparation method of the graphene modified by the silane coupling agent is exactly the same as that of the graphene modified by the silane coupling agent in Example 1.

[0053] The preparation method of the above-mentioned composite coating solution is basically the same as the preparation method of the coating coating solution in Example 1, except that the graphene solution modified by the silane coupling agent is mixed with the epoxy resin solution, wherein the graphene The mass accounts for 0.5% of the epoxy resin E51 mass.

[0054] The above-mentioned composite coating solution was used to prepare a composite coating on the surface of the sub...

Embodiment 3

[0057] In this embodiment, the composite coating solution is composed of solvent, epoxy resin E51 and graphene modified by silane coupling agent. Wherein, the solvent is a mixed solvent formed by mixing xylene and n-butanol at a mass ratio of 7:3, and the mass of graphene accounts for 0.75% of the epoxy resin E51 mass.

[0058] The preparation method of the graphene modified by the silane coupling agent is exactly the same as that of the graphene modified by the silane coupling agent in Example 1.

[0059] The preparation method of above-mentioned composite coating solution is basically the same as the preparation method of composite coating solution in embodiment 1, and difference is: the graphene solution of silane coupling agent modification mixes with epoxy resin solution, wherein the quality of graphene Occupies 0.75% of epoxy resin E51 mass.

[0060] The above-mentioned composite coating solution was used to prepare a composite coating on the surface of the substrate, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com