Piezoelectric conductive epoxy resin composite damping material and preparation method thereof

A technology of composite damping material and conductive epoxy resin, which is used in epoxy resin coatings, epoxy resin glue, conductive materials dispersed in non-conductive inorganic materials, etc. problems, to achieve the effects of anti-static vibration, noise elimination, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

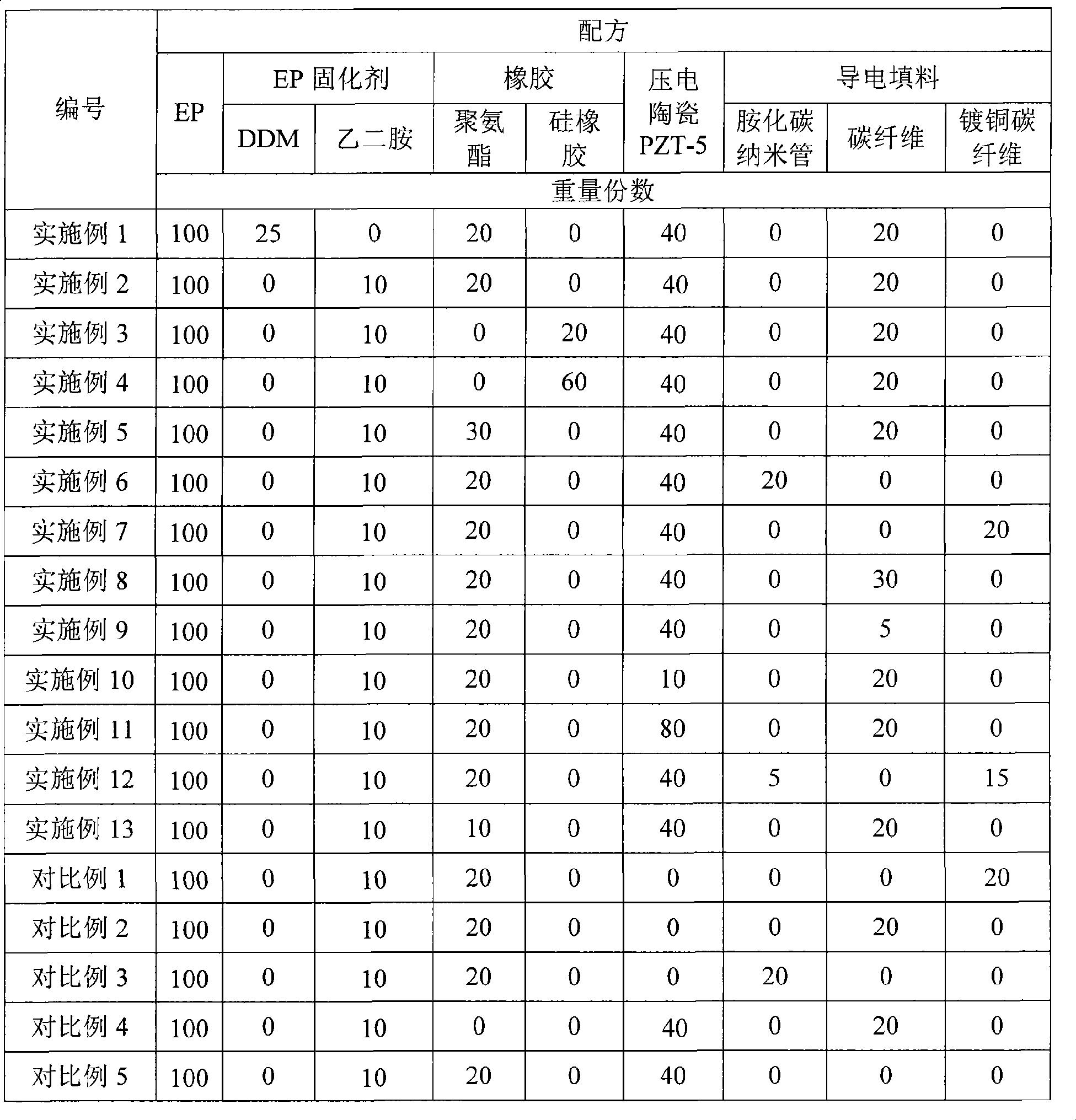

[0033] Below in conjunction with embodiment, further illustrate the present invention.

[0034] Performance Testing:

[0035] Test the damping performance according to "GB / T 18258-2000 Test Method for Damping Properties of Damping Materials"; test the volume resistivity according to the standard "GB / T 15662-1995 Test Method for Volume Resistivity of Conductive and Antistatic Plastics". "GB / T 2570-1995 Test method for flexural properties of resin castings" tests the flexural strength. "GB / T1043-1993 Hard Plastic Charpy Impact Test Method" tests the impact strength.

[0036] Raw material performance indicators and grades:

[0037] epoxy resin :

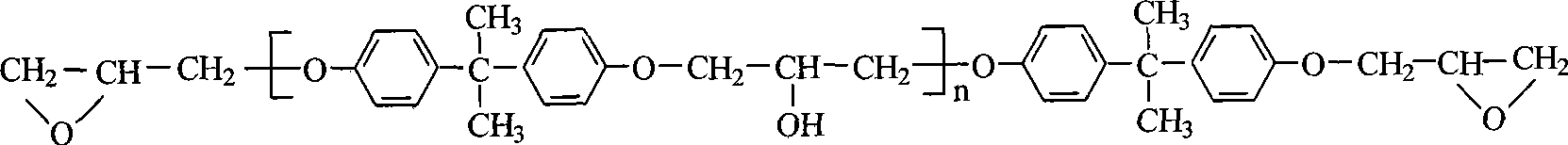

[0038] Type: bisphenol A glycidyl ether type epoxy resin

[0039] Grade: E-51

[0040] Source: Wuxi Diaisheng Epoxy Co., Ltd.

[0041] Molecular formula:

[0042]

[0043] Appearance: Light yellow to yellow transparent viscous liquid with low chlorine content.

[0044] Epoxy value: 0.48~0.54

[0045] Epoxy equivalent (g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com