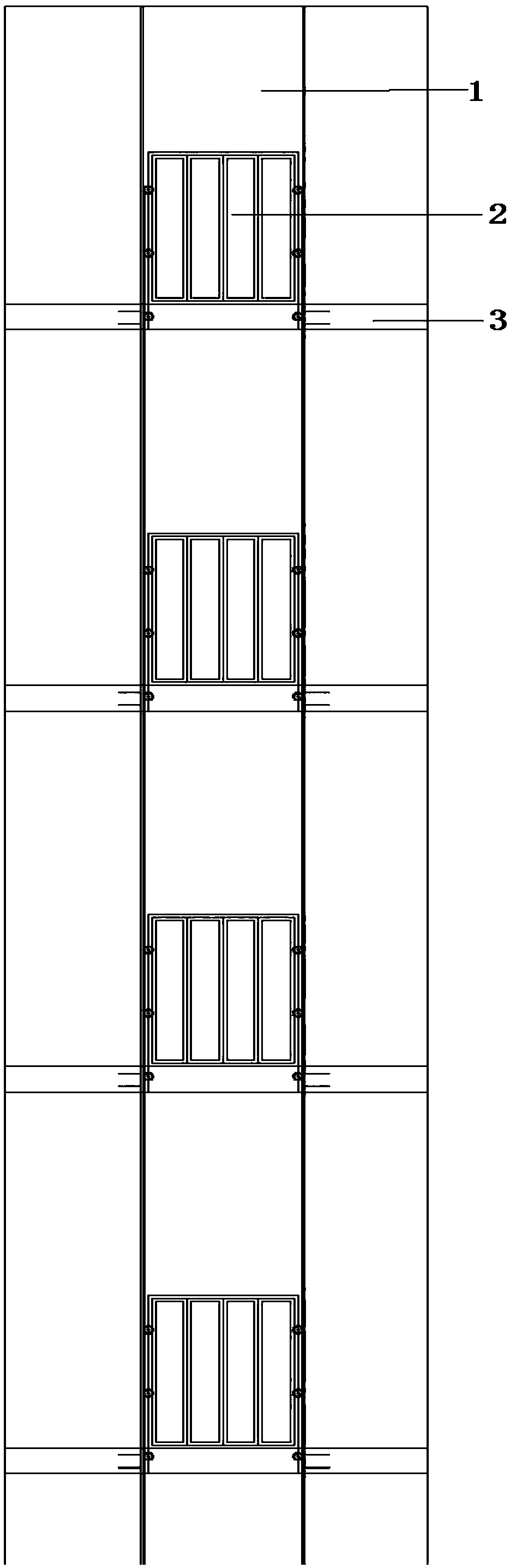

Multi-elevator-car vertical elevator

A multi-car and elevator technology, which is applied to elevators, elevators, transportation and packaging in buildings, etc., can solve the problems of limited space for a single car, limited quantity of single transportation, small building space requirements, etc., and achieve good The effect of promotion prospects, short waiting time, and small effective space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

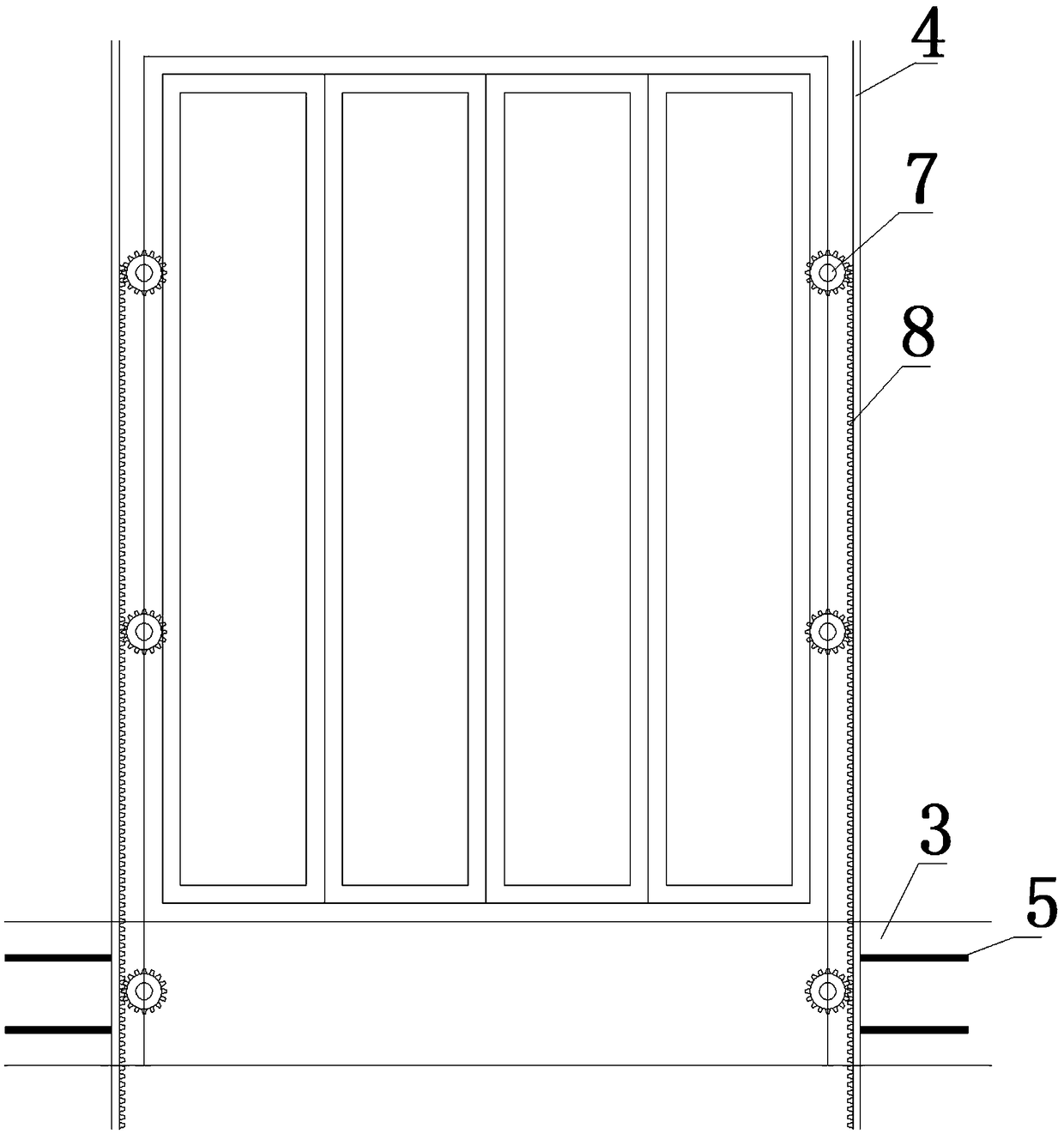

[0042] like Figures 3 to 5 As shown, the driving device includes a power group and several gear sets composed of gears 7 and several racks that cooperate with each other to make the car move up and down. The racks 8 are arranged on the guide rail 4. The gear set and the power set are arranged on the car 2 . The power group drives the gear 7 to move to realize the up and down movement of the car. The power pack can be configured to drive a motor 9 and a rotating shaft 10, the driving motor 9 drives the rotating shaft 10 to rotate, and the rotating shaft 10 drives the gear 7 to move.

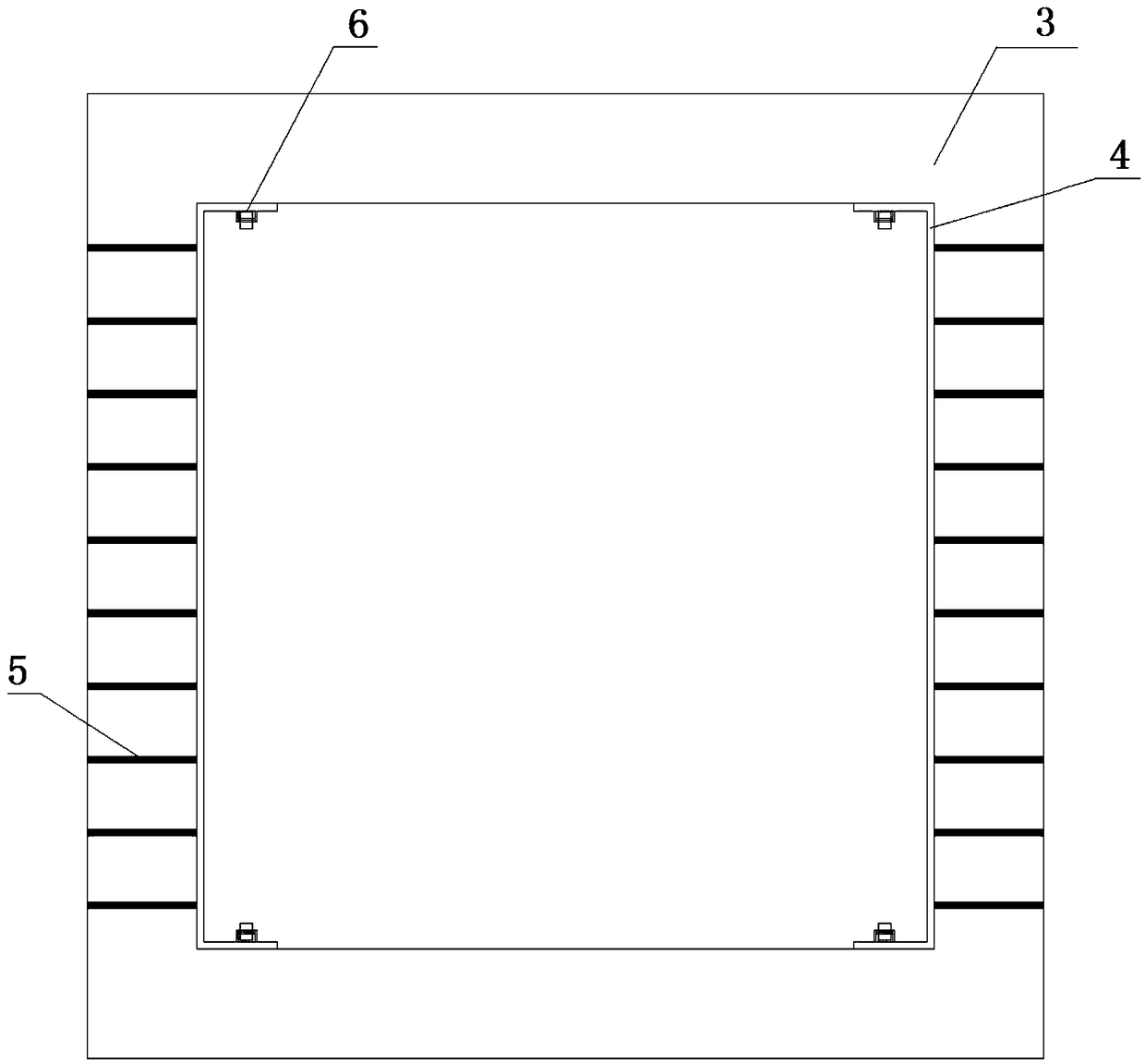

[0043] Specifically, a number of pre-embedded pegs 5 are arranged on the two opposite surfaces of the hoistway, and two racks 8 are respectively arranged on the two surfaces of the guide rail 4 corresponding to the pre-embedded pegs 5 , and the racks 8 on the two opposite surfaces of the guide rail 4 are connected to each other. parallel. The racks 8 are arranged in sections on the guide rails...

Embodiment 2

[0052] like Figures 6 to 9 As shown, compared with Embodiment 1, the difference is that the installation positions of the gear set and the rack are interchanged, that is, the rack 8 is arranged on the car 2, and the gear set is arranged on the guide rail 4. Correspondingly, use The power pack that moves with the driving gear is arranged on the position corresponding to the gear 7 .

[0053] When the elevator door is closed, the central controller starts all the driving motors 9, the driving motors 9 drive the rotating shaft 10 to rotate, the rotation of the rotating shaft 10 drives the gear 7 to move, and under the push of the gear 7, all the cars equipped with the rack 8 Run steadily up or down.

[0054] When there is no steel truss installed between the car 2 and the car 2, the vertical direction of the guide rail 4 evenly distributes the gear sets, and ensures that in any state of the elevator, the number of gear racks and gear sets on all car 2 is quite large in 2 group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com