Oil-gas lubrication method

An oil-gas lubrication and oil-gas technology, which is applied in the fields of oil-gas lubrication of steel rolling machinery and bearings of cold-rolling equipment, can solve the problems of short transportation distance, environmental pollution, harmful health, etc., and achieve strong oil and gas transportation capacity, high promotion value, and transportation long distance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

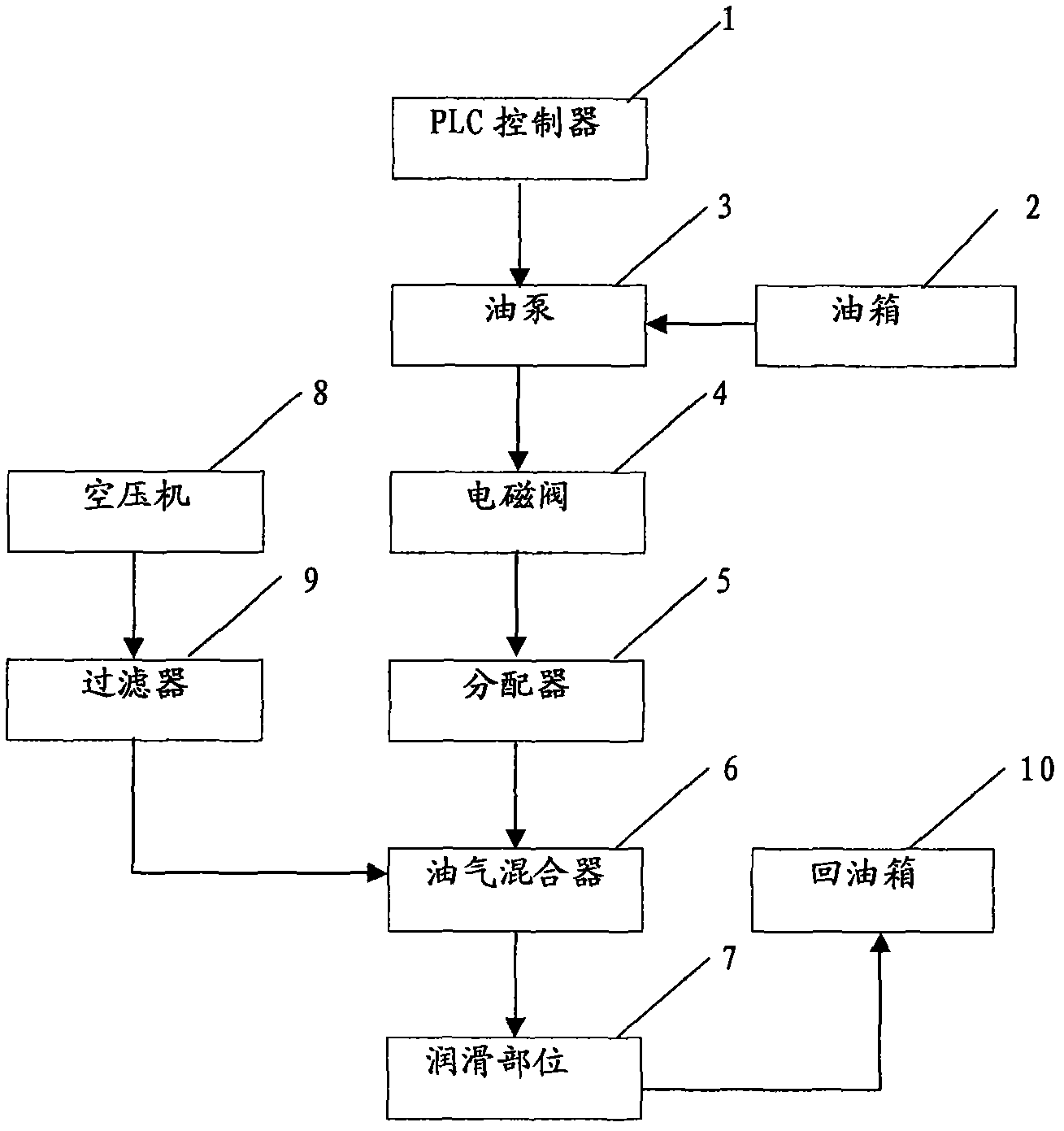

[0018] Adoption of an oil mist lubrication method, the PLC control system 1 starts the oil pump 3 according to the set operating parameters, and the lubricating oil in the oil tank 2 is sent to the distributor 5 through the solenoid valve 4, and the lubricating oil is accurately measured and collected by the distributor 5 Distribution, sent to the oil-air mixer 6, at the same time, the air compressor 8 sends the compressed air to the oil-air mixer 6 after being filtered by the filter 9, and the oil-gas state is synthesized in the oil-air mixer 6, and the oil flow continuously supplies oil to the lubricating part 7 Realize effective lubrication; the airflow can also effectively reduce the temperature of the bearing; the overpressure formed in the bearing by oil-air lubrication has a good sealing effect, which can prevent the emulsion and dirt from entering the bearing seat; the oil receiving device of the bearing can transfer the lubricating oil Recovery, the recovered lubricati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com