Blank conveying system for automatic elevator guide rail machining production line

An elevator guide rail, automatic processing technology, applied in metal processing, manufacturing tools, transportation and packaging, etc., can solve the problems of occupying a large production workshop, long feeding device length, etc., to save installation space, strong conveying capacity, reliable action Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

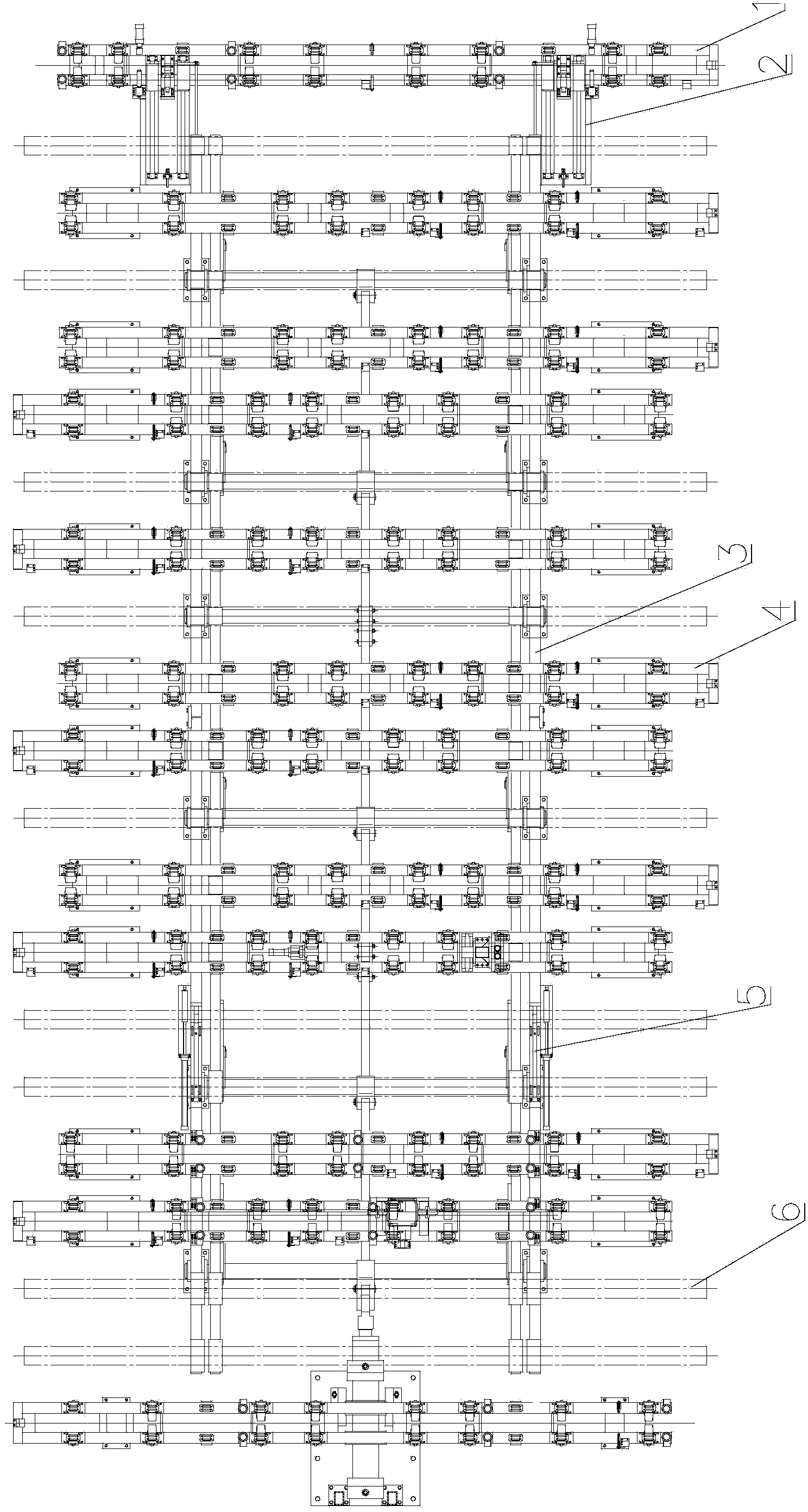

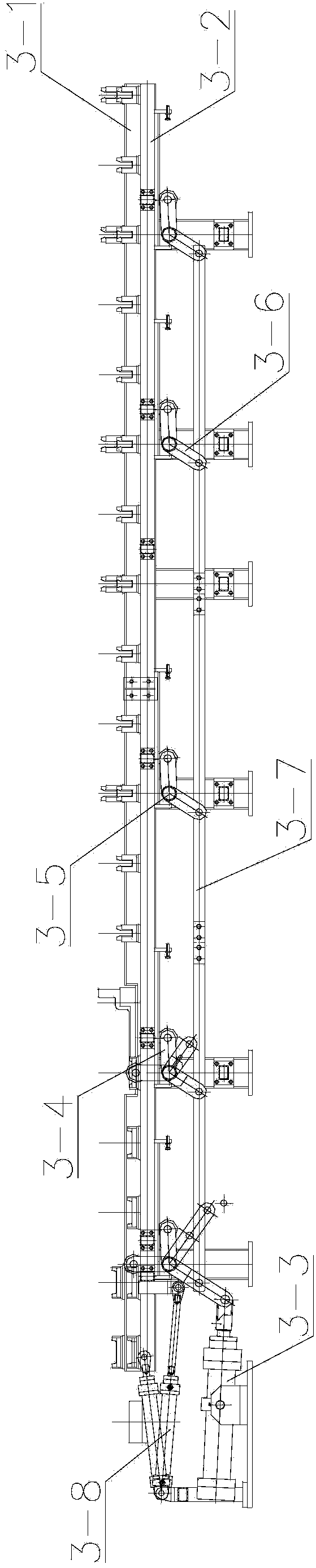

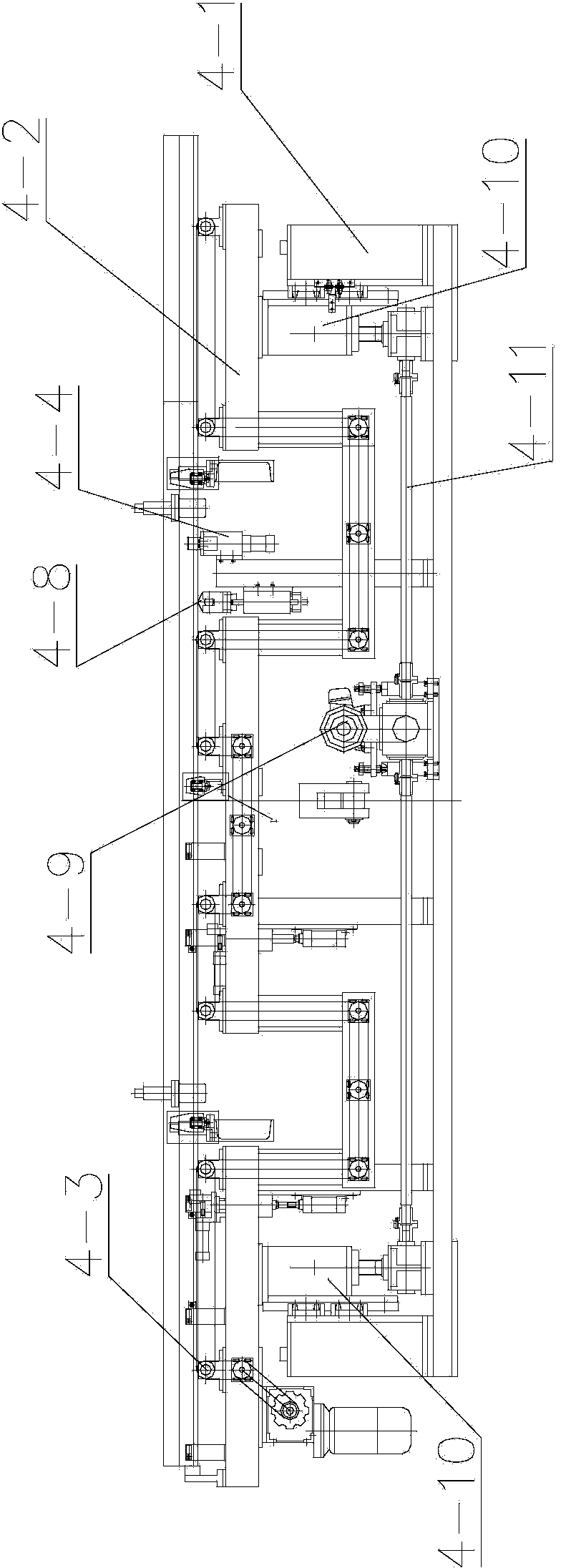

[0026] Elevator guide rail automatic processing production line, including elevator guide rail milling processing unit, elevator guide rail male and female tenon processing unit, elevator guide rail mounting hole processing unit, elevator guide rail countersinking processing unit and blank conveying system;

[0027] The elevator guide rail milling processing unit, the elevator guide rail male and female tenon processing unit, the elevator guide rail mounting hole processing unit and the elevator guide rail countersinking processing unit are arranged side by side horizontally;

[0028] The elevator guide rail milling processing unit includes a first elevator guide rail milling processing device and a second elevator guide rail milling processing device, and the two elevator guide rail milling processing devices are vertically and laterally staggered from each other;

[0029] The elevator guide rail yin and yang processing unit includes the first elevator guide rail yin and yang ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com