Efficient positive-pressure pneumatic conveying system of pebble coal

A pneumatic conveying system, the technology of pebble coal, applied in the direction of conveyor, conveying bulk materials, transportation and packaging, etc., can solve the problems of easy failure, loud Roots fan noise, wear and tear of pipes and equipment, etc., to enhance the conveying capacity, The effect of strong conveying capacity and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

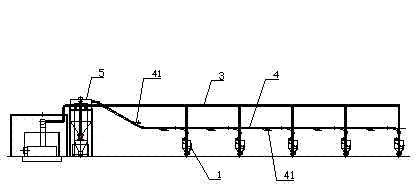

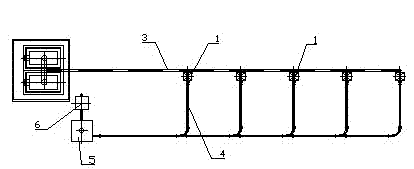

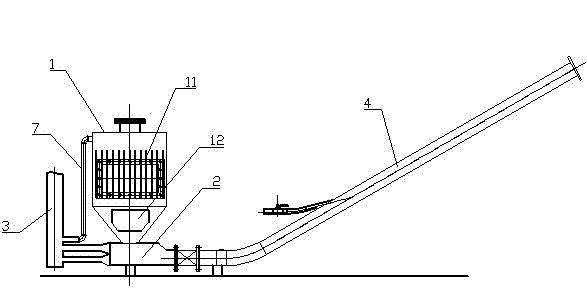

[0024] Such as figure 1 As shown in -3, the high-efficiency pebble coal positive pressure pneumatic conveying system includes a pebble coal bunker 1 whose upper end is connected to the pebble coal outlet of the medium-speed coal mill, and the lower end outlet of the pebble coal bunker is connected to a feeding device 2. The inlet of the front end of the device 2 is connected to the compressed air pipeline 3, the outlet of the rear end of the feeding device 2 is connected to the pebble coal hopper 5 through the conveying pipeline 4, and the gas outlet of the pebble coal hopper is exhausted through the dust collector 6. A section of connecting pipe 7 is connected between the compressed air pipeline 3 and the upper space of the gravel coal bunker 1 to keep positive pressure in the gravel coal bunker. A vibrating screen 11 is arranged between the upper end inlet and the lower end outlet of the stone coal bunker 1 to separate large pieces of stone coal that are not suitable for pne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com