Permanent magnet carrier roller belt conveyor

A belt conveyor and idler technology, which is applied in the direction of conveyor objects, rollers, transportation and packaging, etc., can solve the problems of expensive conveyor belts, unsuitable for on-site production work, power resource dependence and consumption, etc., and achieve reduction Production costs and operation and maintenance costs, reduce production and maintenance costs, overcome the effects of frictional heat generation and vibration noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

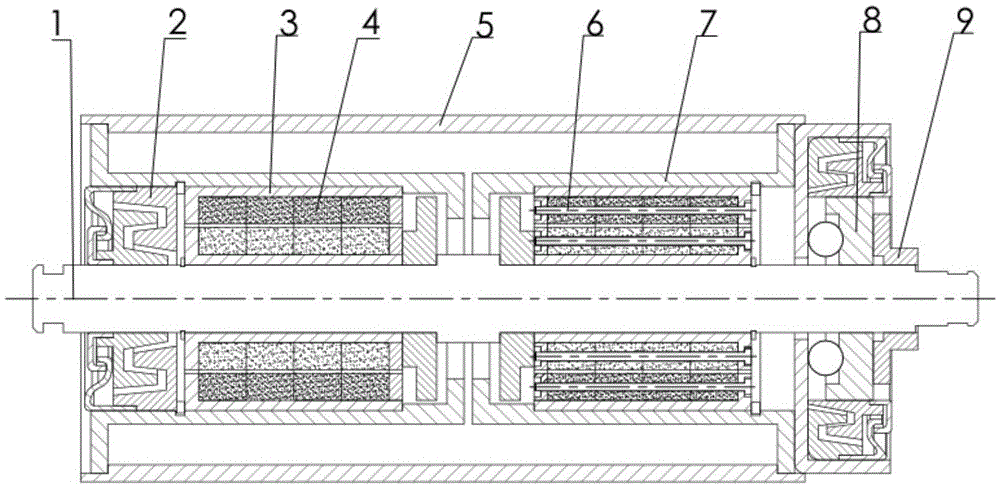

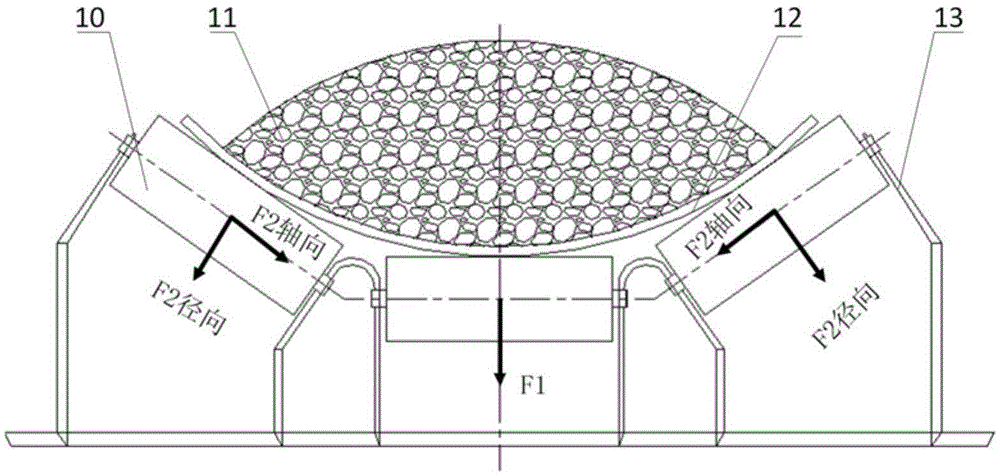

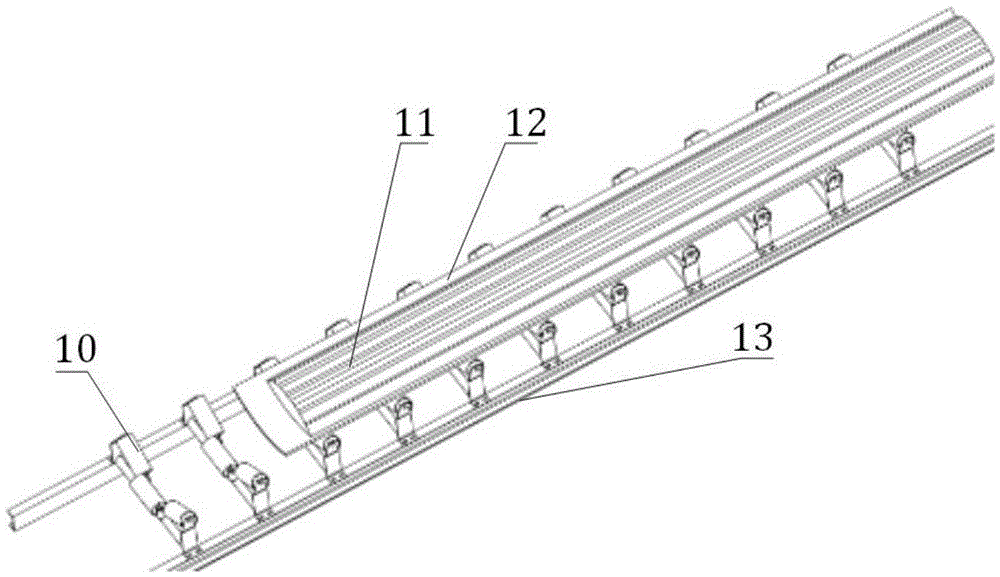

[0028] The invention discloses a permanent magnetic idler belt conveyor, which can realize the radial permanent magnetic suspension support function, and the idler support mode is realized by radial permanent magnetic bearings and axial thrust ball bearings. The radial permanent magnetic bearing is composed of superimposed inner and outer permanent magnetic rings to generate repulsive force to complete the radial support; the axial thrust ball bearing is clamped by a lock nut to balance the inner and outer rings of the radial permanent magnetic bearing. The axial magnetic force generated by the axial relative displacement of the outer magnetic ring completes the axial support and realizes the stable suspension of the idler roller.

[0029] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0030] The permanent magnet idler belt conveyor provided by the invention, such as figure 1 As shown, a labyrinth seal 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com