Elliptical track vibrating screen

An elliptical trajectory, vibrating screen technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of single projection angle of linear vibrating screen, poor material conveying capacity, inconvenient amplitude adjustment, etc., to achieve high screening efficiency, The effect of strong conveying capacity and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

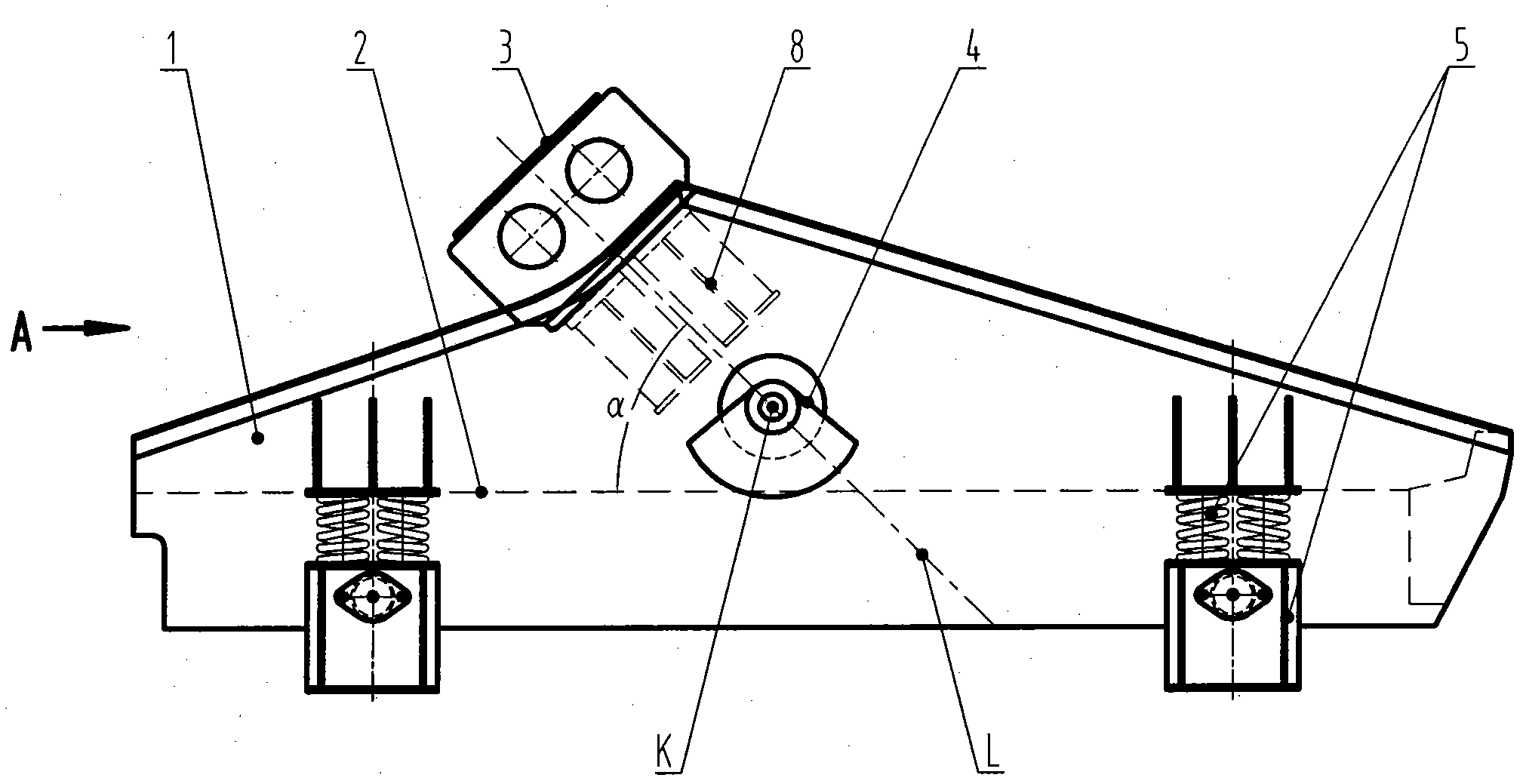

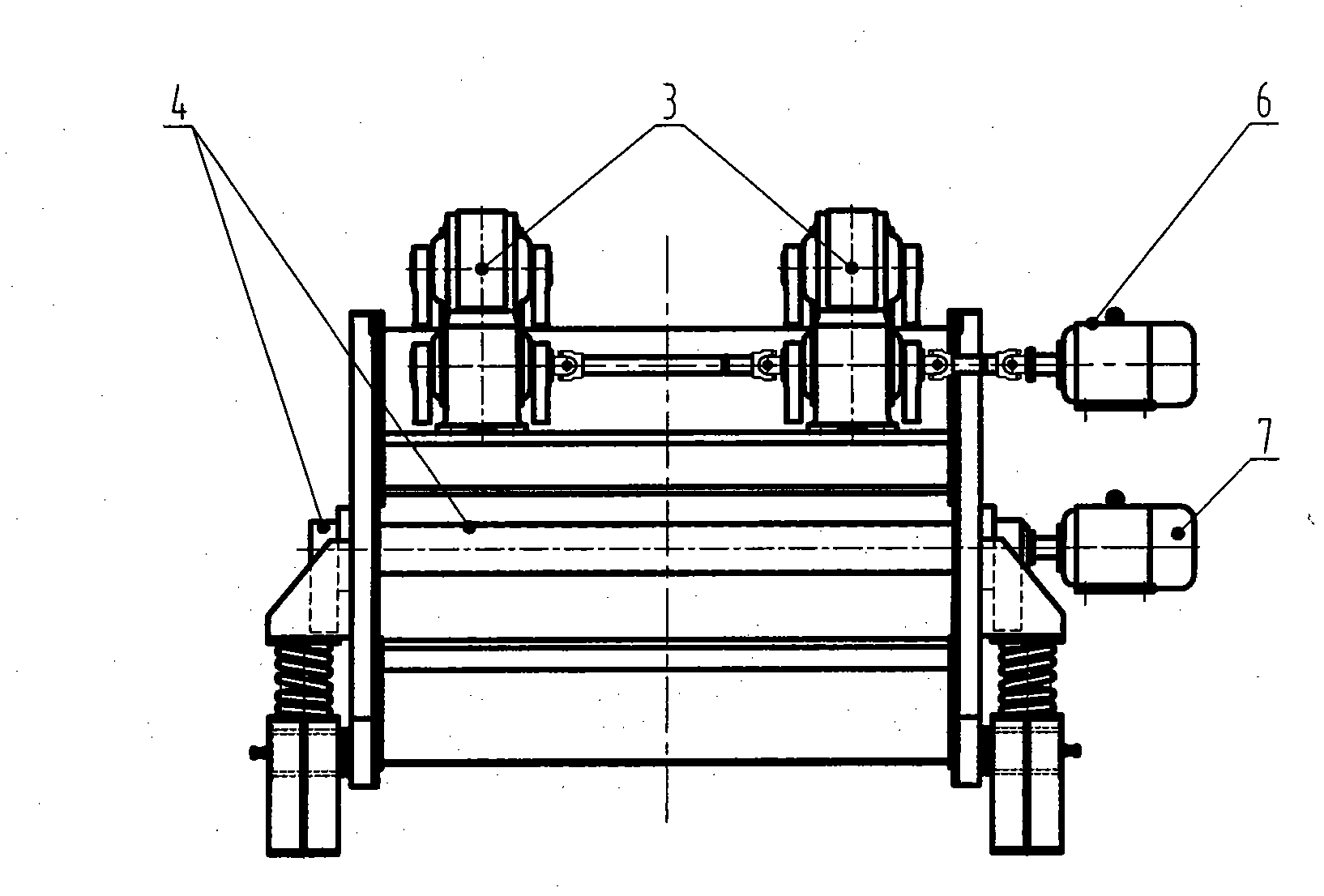

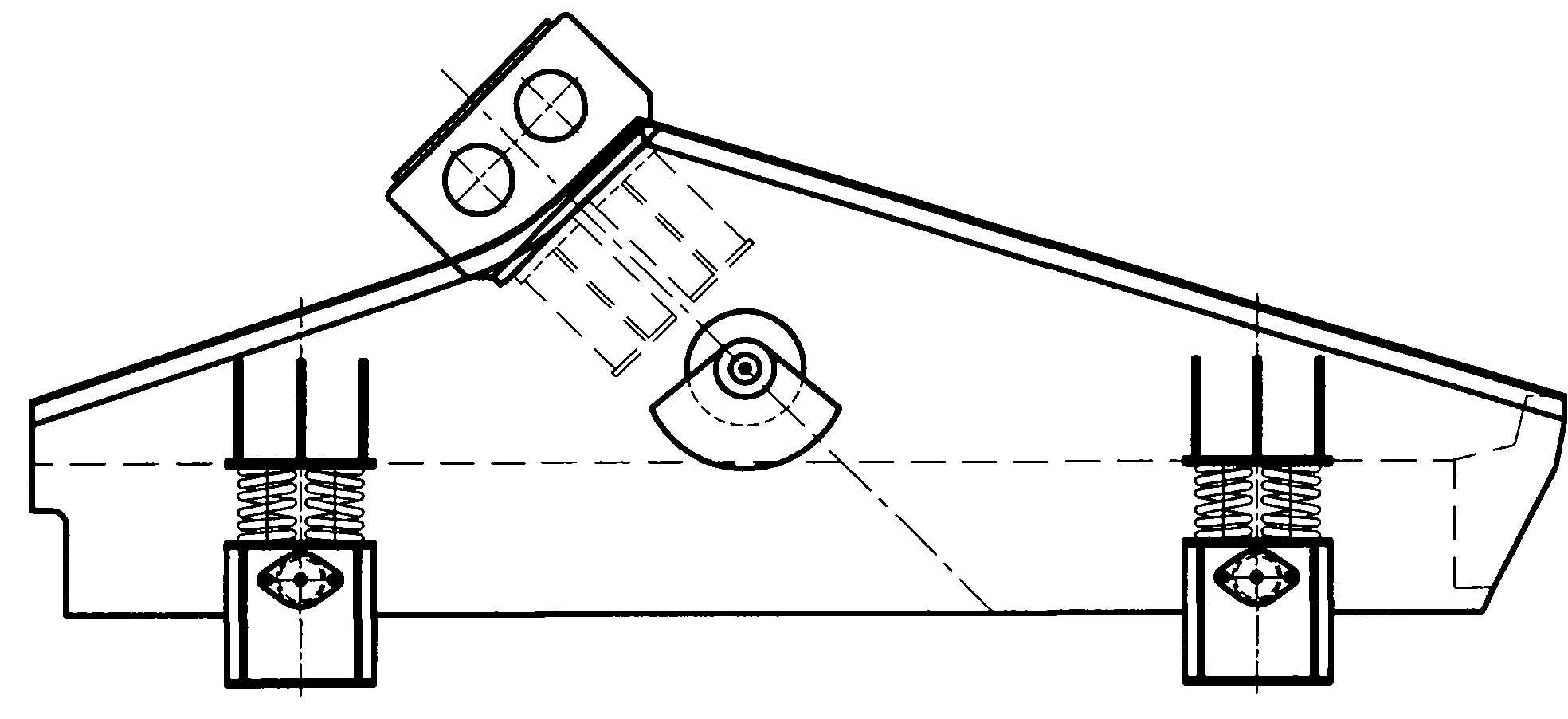

[0008] An embodiment of the present invention is described below in conjunction with the accompanying drawings. It consists of a screen box composed of a screen frame 1 and a screen surface 2, a vibration exciter 3, 4, a vibration damping support device 5, and a motor transmission device 6, 7. The synchronous vibrator 3 is installed on the top of the driving main beam 8 on the screen frame 1, and the two shafts rotate in the opposite direction through gears with equal parameters and a transmission ratio of 1, and the motor transmission device 6 is connected with one shaft of the vibrator , the resultant line of action L that produces excitation passes through the center of mass K of the vibrating screen box, so that the screen box forms a linear vibration track in the longitudinal plane, and the vibration direction angle α is 45°. The single-axis vibrator 4 is installed on the two side plates of the screen frame 1, the center is located on the resultant force line L of the doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com