Active-passive mixer

A mixer and main body technology, applied in the field of active-passive mixers, can solve the problems of limited fluid pumping energy, inability to accurately control the pumping volume, and the mixing effect and mixing ratio accuracy of piezoelectric fluid mixers need to be further improved. , to achieve the effect of strong fluid conveying capacity, good mixing effect and high proportioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

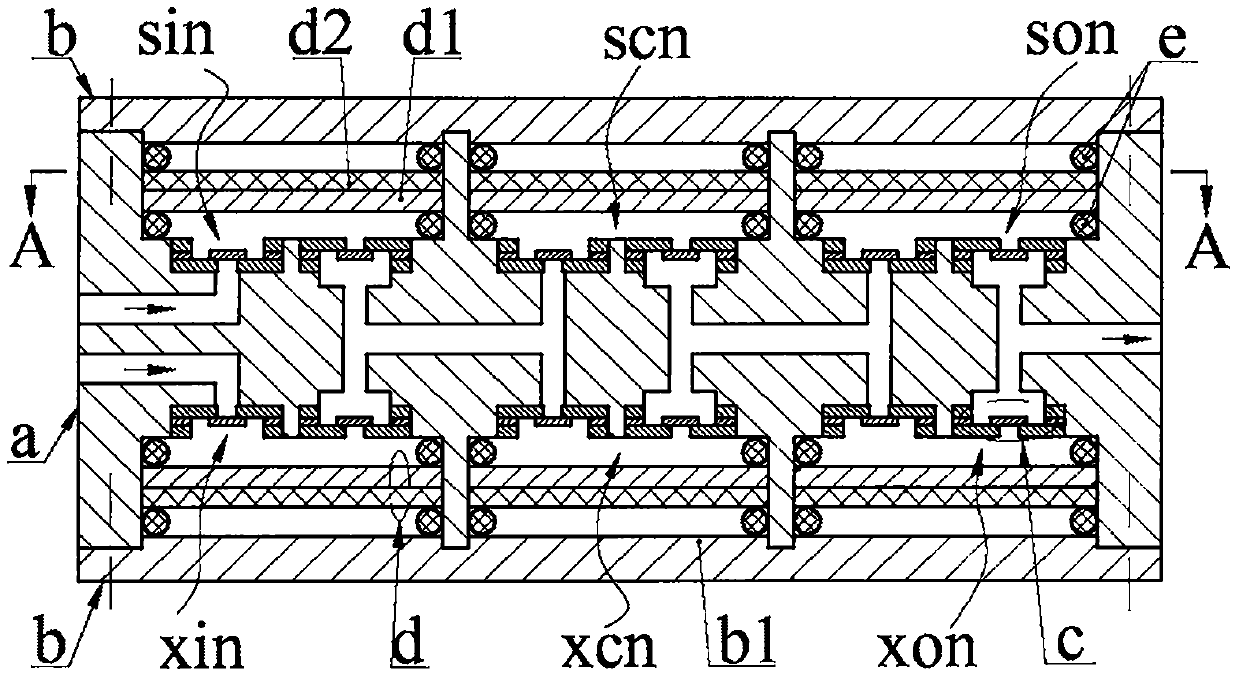

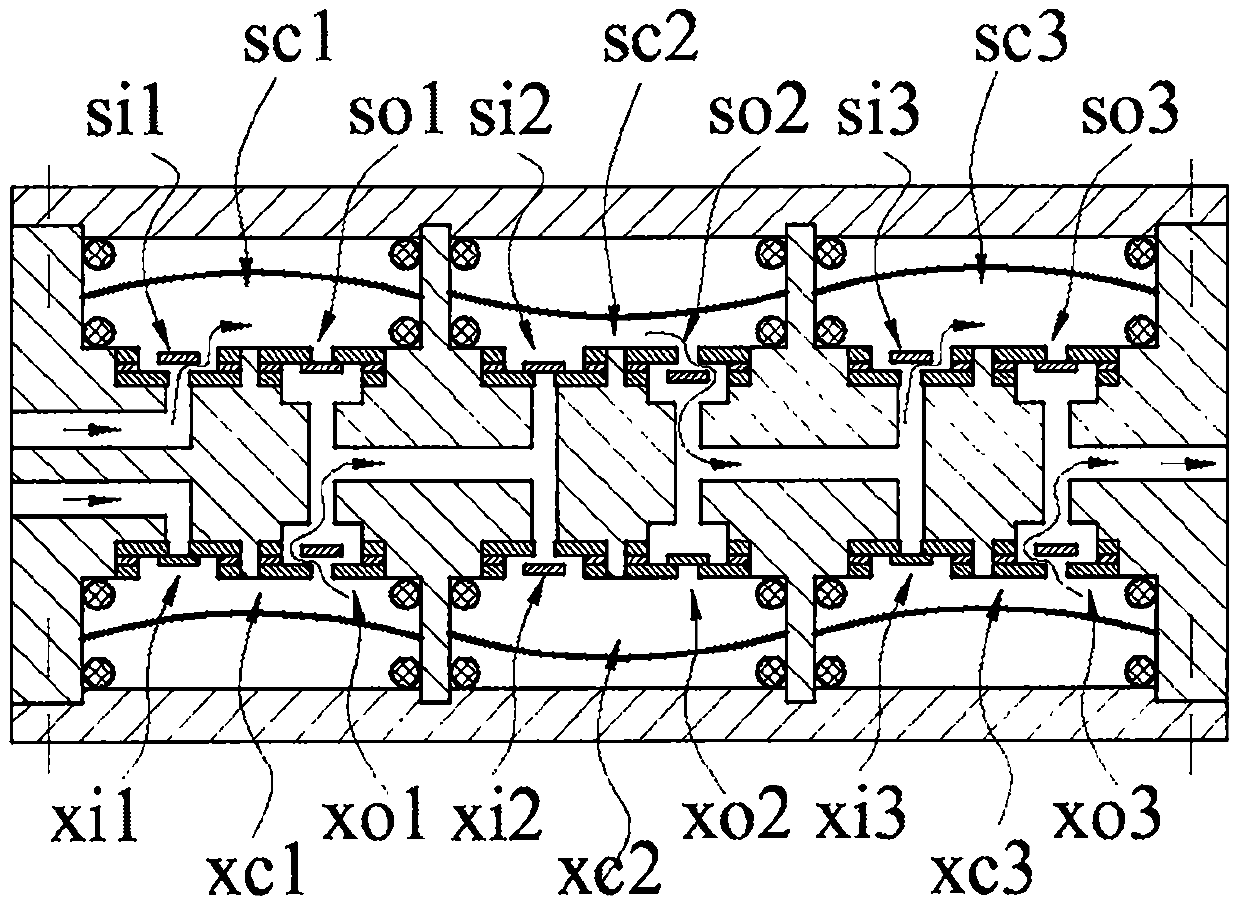

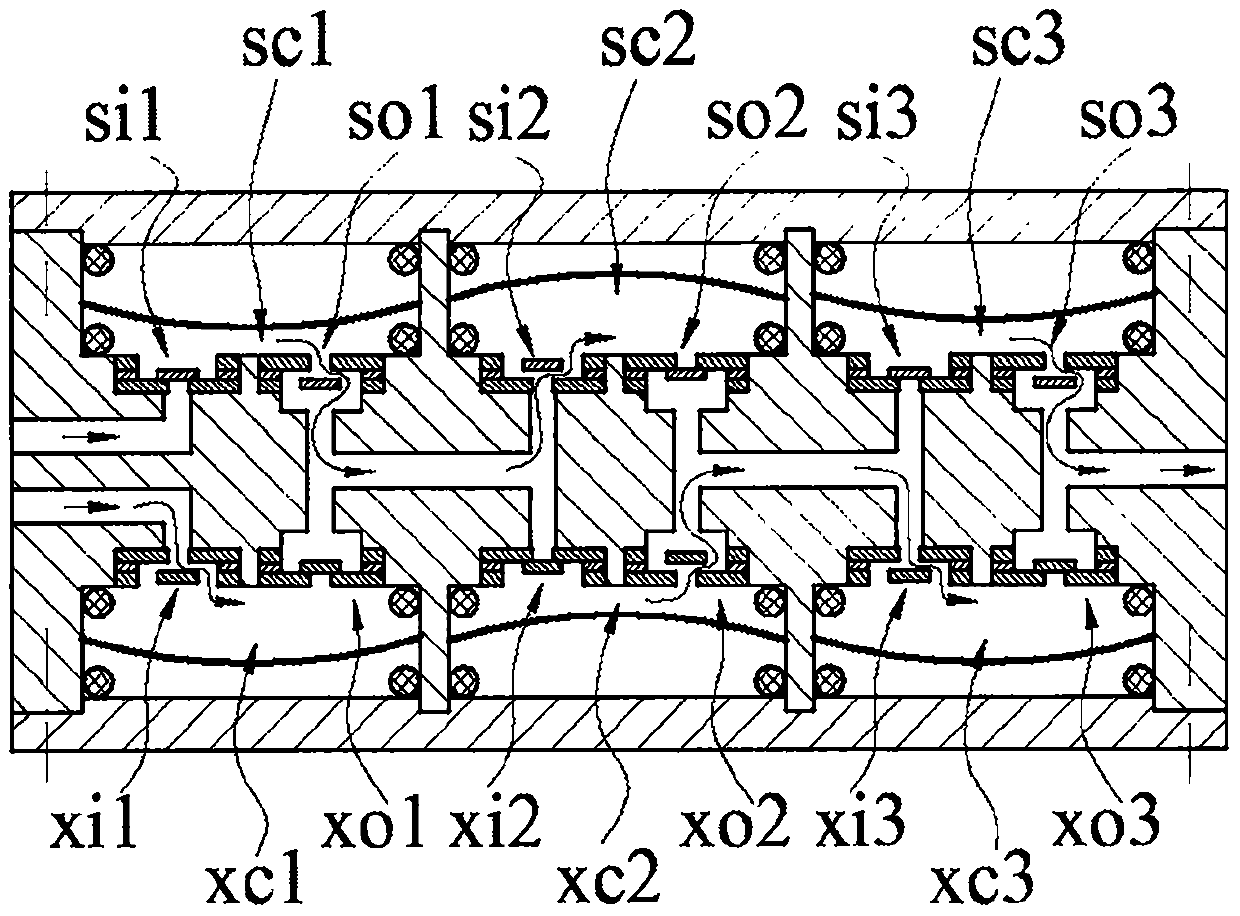

[0016] The main body a is provided with an upper inlet hole a1, a lower inlet hole a1', an outlet hole a2, an upper sinking cavity a3, and a sinking cavity a4. The trunking a5, the bottom wall of the upper sinking cavity a3 are provided with the upper inlet a6 and the upper outlet a7, and the top wall of the sinking cavity a4 is provided with the lower inlet a6' and the lower outlet a7'; The upper sinking cavity a3 and the lower sinking cavity a4 arranged laterally symmetrically constitute a sinking cavity group, and the upper inlet cavity a6 and the lower inlet cavity a6' of the leftmost sinking cavity group communicate with the upper inlet hole a1 and the lower inlet hole a1' respectively, and the last The upper outlet a7 and the lower outlet a7' of the right sunken cavity group are connected with the outlet a2, the upper inlet a6 and the lower inlet a6' of the other sunken cavity groups are connected through the inlet a8, and the upper outlet a7 and the lower outlet are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com