A kind of magnetic hot melt adhesive and its preparation and use method

A magnetocaloric and melt-adhesive technology, applied in the direction of bonding methods, adhesives, adhesive additives, etc., can solve the problems of impossible heating separation, environmental pollution, etc., to avoid the generation of temperature gradient, easy to operate, improve bonding strength and The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

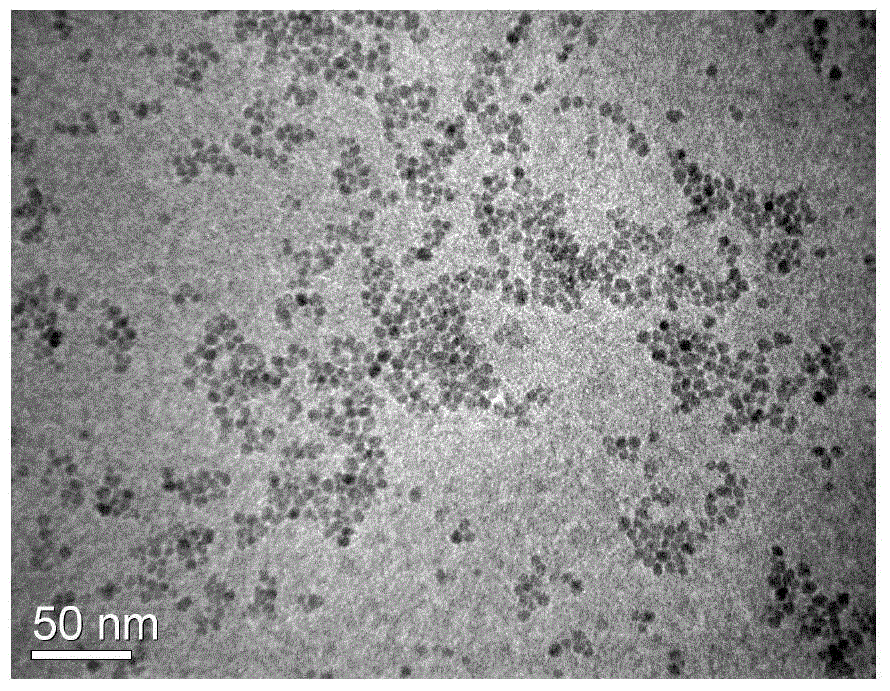

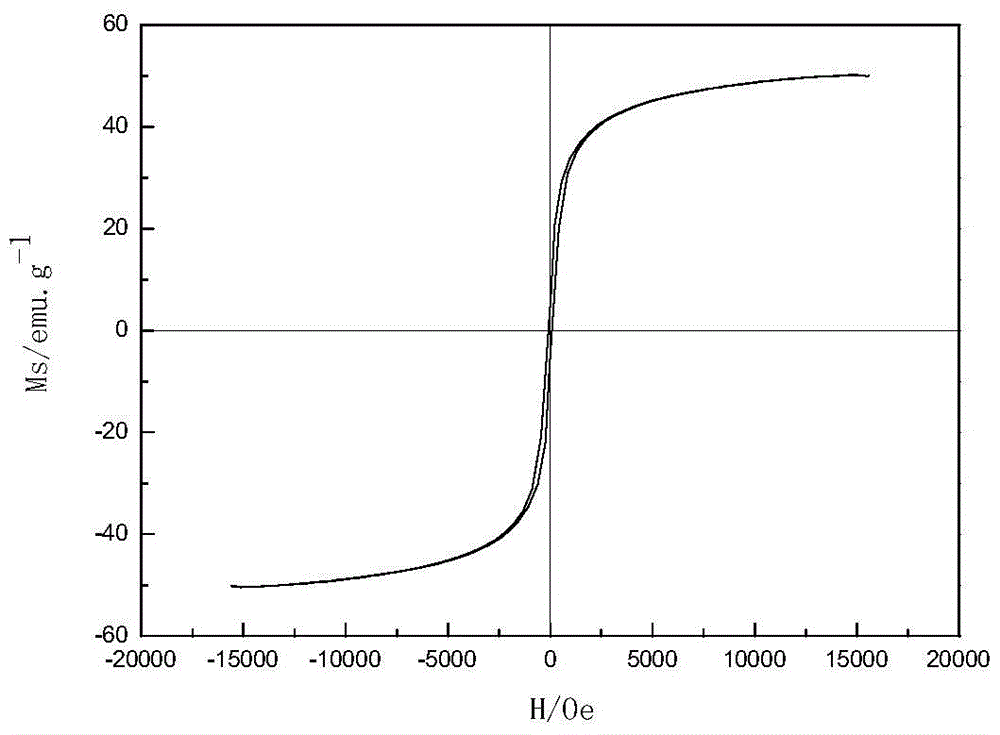

[0037] The preparation method of nickel-zinc, manganese-zinc and cobalt-zinc ferrite: adding iron acetylacetonate, zinc acetylacetonate and nickel acetylacetonate or manganese acetylacetonate or cobalt acetylacetonate with a molar ratio of 4:1:1 to ethylene glycol , heated in an Ar protective atmosphere, kept at 80-90°C for 10-30 minutes; then slowly raised to 170-200°C and held for 2-5 minutes, then rapidly raised to 255-265°C, refluxed for 50-90 minutes, and finally cooled to room temperature naturally Add absolute ethanol to the reaction solution to obtain a black reaction solution; centrifuge the solution, wash the precipitate repeatedly with absolute ethanol for 3 to 5 times, and finally vacuum-dry the washed black precipitate to obtain Ni 0.5 Zn 0.5 Fe 2 o 4 , Mn 0.5 Zn 0.5 Fe 2 o 4 or Co 0.5 Zn 0.5 Fe 2 o 4 Nano ferrite powder.

[0038] The method for surface modification of magnetic nano-ferrite powder is as follows: Weighing an appropriate amount of nano-po...

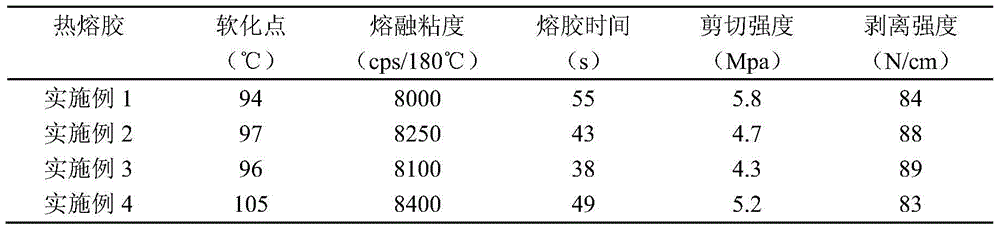

Embodiment 1

[0040] 25 kg of EVA, 22.5 kg of rosin, 4.5 kg of polybutadiene, 5 kg of Sasol synthetic wax, 0.5 kg of antioxidant 1010, and surface-modified magnetic manganese zinc ferrite nano 8 kilograms of powder; the softening point of the Sasol synthetic wax is between 110° C. and 120° C.; the plasticizer is low-molecular polybutadiene with a molecular weight of 2300.

[0041] Put rosin, antioxidant 1010, and Sasol synthetic wax into the container according to the formula dosage, and heat it to above 60°C, stir evenly to melt the above mixture; after the materials are completely melted, add the formula amount of EVA and polybutane ene, stir evenly at 150-180°C; after complete melting and mixing, add the surface-modified magnetic manganese-zinc-ferrite nano-powder in the formula amount, and stir evenly; stop heating the mixed molten material to make the temperature Lower to no higher than 130°C, then filter the above molten material through a 200-mesh filter; take the filtered molten mat...

Embodiment 2

[0046] 52 kg of EEA, 41.2 kg of coumarone resin, 3.6 kg of dibutyl phthalate, 11 kg of microcrystalline wax, 1.2 kg of thiodipropionate, and surface-modified 20 kg of magnetic nickel-zinc ferrite nanopowder; the softening point of the microcrystalline wax is between 60°C and 90°C.

[0047] Put the coumarone resin, thiodipropionate, and microcrystalline wax into the container according to the amount of the formula, and heat it to above 60°C, stir evenly to melt the above mixture; after the materials are completely melted, add the amount of the formula respectively EEA, dibutyl phthalate, stir evenly at 150-180°C; after complete melting and mixing, add the surface-modified magnetic nickel-zinc ferrite nano-powder in the formulated amount, and stir evenly; mix the Stop heating the molten material to lower its temperature to no higher than 130°C, and then filter the above molten material through a 300-mesh filter; take the filtered molten material and place it in an extruder, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com