Production method for particle reinforced aluminum matrix composite ingots

A composite material and production method technology, which is applied in the field of manufacturing cast particle reinforced aluminum matrix composite material blanks, can solve the problems of high cost, expensive equipment, complicated production process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

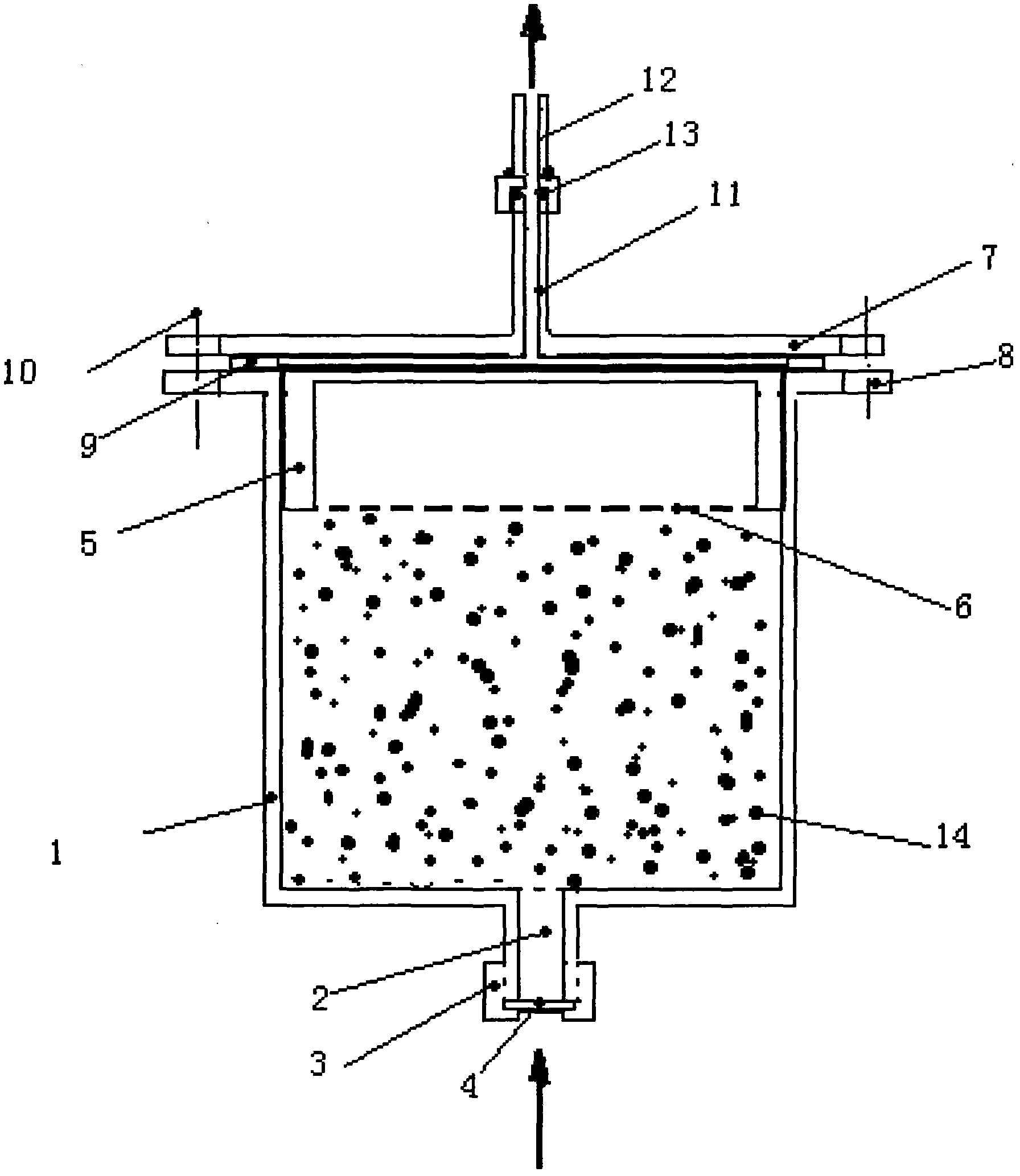

Method used

Image

Examples

Embodiment Construction

[0045] 35%B 4 C p / 6061 Billet Manufacturing

[0046] The main indicators stipulated by relevant departments for the development method conditions of AP100 chrome-aluminum ceramic neutron absorbing plate include: chromium boron carbide particle reinforced aluminum matrix composite material, the plate size is 4370x190X (2.7-6.0) mm, the substrate is aluminum alloy 6061 (including certain chromium element), boron carbide content 31-45%, tensile strength not less than 275MPa, yield strength not less than 230MPa, elongation not less than 2%, 60-year lifespan (including accelerated corrosion, accelerated irradiation, short-term and long-term high temperature experiments, etc.). The trial production of nuclear fuel grid shielding plate adopts the following production process: powder mixing - ball pressing - sintering - vacuum - vacuum pressure impregnation - billet - hot extrusion - annealing - warm rolling - straightening - anodization -shear-product. In the above process, bill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com