All-solid-state lithium ion battery and fabrication method thereof

A lithium-ion battery, all-solid-state technology, applied in electrolyte battery manufacturing, electrode manufacturing, secondary battery and other directions, can solve the problems of fast battery decay, increase interface impedance, high interface impedance, and achieve the effect of convenient assembly and reduced manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

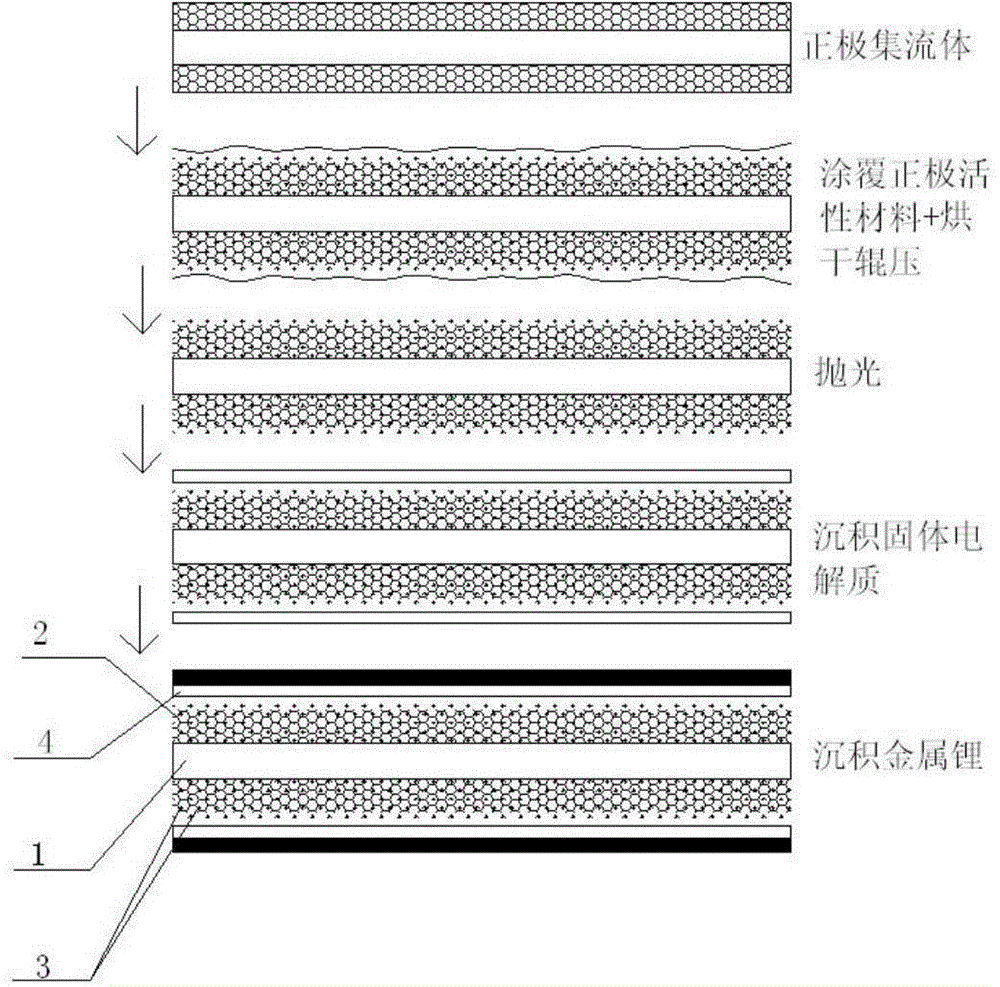

Embodiment 1

[0039] figure 1 Among them, the positive electrode current collector 1 includes a metal foil and a positive electrode three-dimensional three-dimensional porous structure layer 2 obtained by surface modification of the metal foil. The positive electrode current collector 1 and the positive electrode three-dimensional porous structure layer 2 generally use the same metal material. The porous layer is located on the two surfaces of the positive electrode current collector, and the two are bonded by metal bonds to ensure the bonding strength and electronic conductivity. Eliminate the use of conductive agents. The positive electrode active material layer 3 enters the positive electrode three-dimensional porous structure layer 2 in an embedded manner. This three-dimensional structure enables the active material and the current collector to contact in a larger-than-surface manner to enhance the conductivity of the electrode and at the same time act as a fastening activity. The role...

Embodiment 2

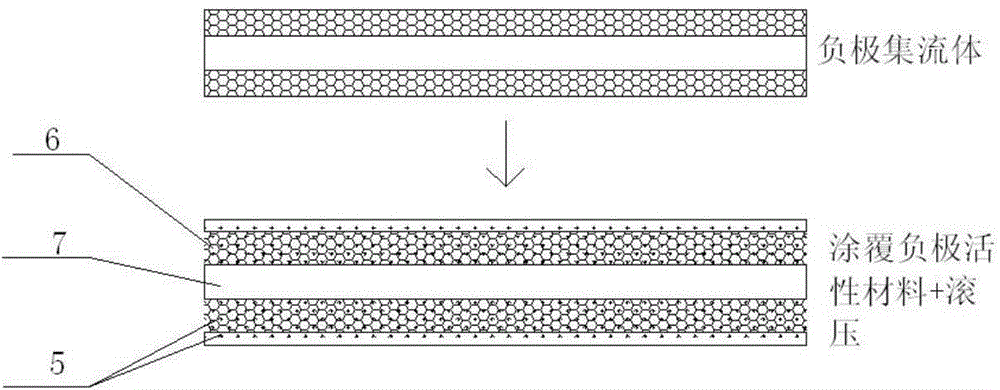

[0041] The positive current collector is a non-porous 10-micron copper foil. The positive electrode material is LCO micron-sized powder with an average particle size of 2 microns. The positive electrode slurry is composed of 96% positive electrode active material, 2% VGCF conductive agent, 2% PAI (NMP is solvent) binder, and the solid content ratio is 55% when mixing. After that, the slurry was coated on the copper foil with a coater, and the thickness was controlled to be 40 microns. After drying at 180C, rolling was performed, and the final compacted thickness of the positive active material layer was 20 microns. The solid electrolyte LiPON was deposited on the smooth cathode surface by vacuum electron beam evaporation with a thickness of 2 μm. The thickness of the connecting layer lithium metal is 100 nanometers, which is deposited on the surface of the solid electrolyte by vacuum hot-dip method. The negative electrode current collector is a 10-micron non-porous copper f...

Embodiment 3

[0043] The same as Example 2, the difference is that the positive electrode current collector has a three-dimensional porous structure as a whole, and the positive electrode active material is coated with the current collector from the front and back surfaces in a three-dimensional embedding manner; the thickness of the positive electrode current collector is 20 microns; The thickness of the active material layer is 20 microns; the negative active material layer is 10 microns metal lithium; the thickness of the solid electrolyte is less than 2 microns; the thickness of the metal lithium connection layer is 1 micron; the surface roughness of the polished positive active material is less than 2 microns; the negative electrode lithium and lithium connection layer Butt, vacuum-packed with packaging aluminum-plastic film, and apply a small amount of pressure under the heating condition of 130C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com