Eliminating scaling powder device and method used for hard disk drive printed circuit board (PCB) processing

A technology of flux and hard disk, used in the cleaning/polishing of conductive patterns, secondary processing of printed circuits, etc., can solve the problem of not being suitable for local cleaning of PCB/PCBA, etc., and achieve the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

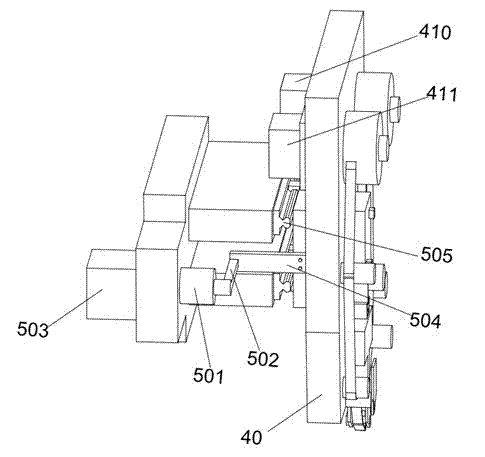

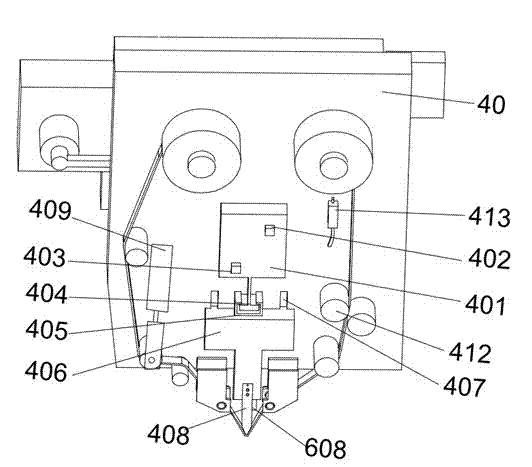

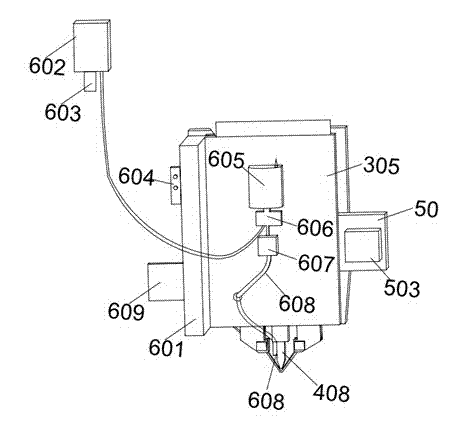

[0033] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a flux removal device and method for processing hard disk PCBs, which can partially clean the PCB / PCBA without the problem of repeated pollution. Specific instructions are given below.

[0034] figure 1 It is a partial schematic diagram of an embodiment of the flux removal device for processing hard disk PCB of the present invention. As shown in the figure, the flux removal device includes a link movement system, a wiping execution system, an automatic switching system for a dust-free cloth, a solvent addition control system and a control system.

[0035] Such as figure 1 , the connecting rod motion system includes a wiping stepper motor 503, a wiping stroke control slide rail 505, a swing mechanism connecting plate 504 connected to the output shaft of the wiping steppin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com