Preparation of solid fluorescent carbon dots and application thereof in aspect of latent fingerprint detection

A solid-state fluorescence and latent fingerprint technology, which is applied in applications, luminescent materials, diagnostic recording/measurement, etc., can solve the problems of poor resolution of fluorescent fingerprints, enlarged nanoparticle size, cumbersome preparation process, etc., and achieve excellent solid-state fluorescence The properties and preparation method are simple and fast, and the raw materials are safe and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

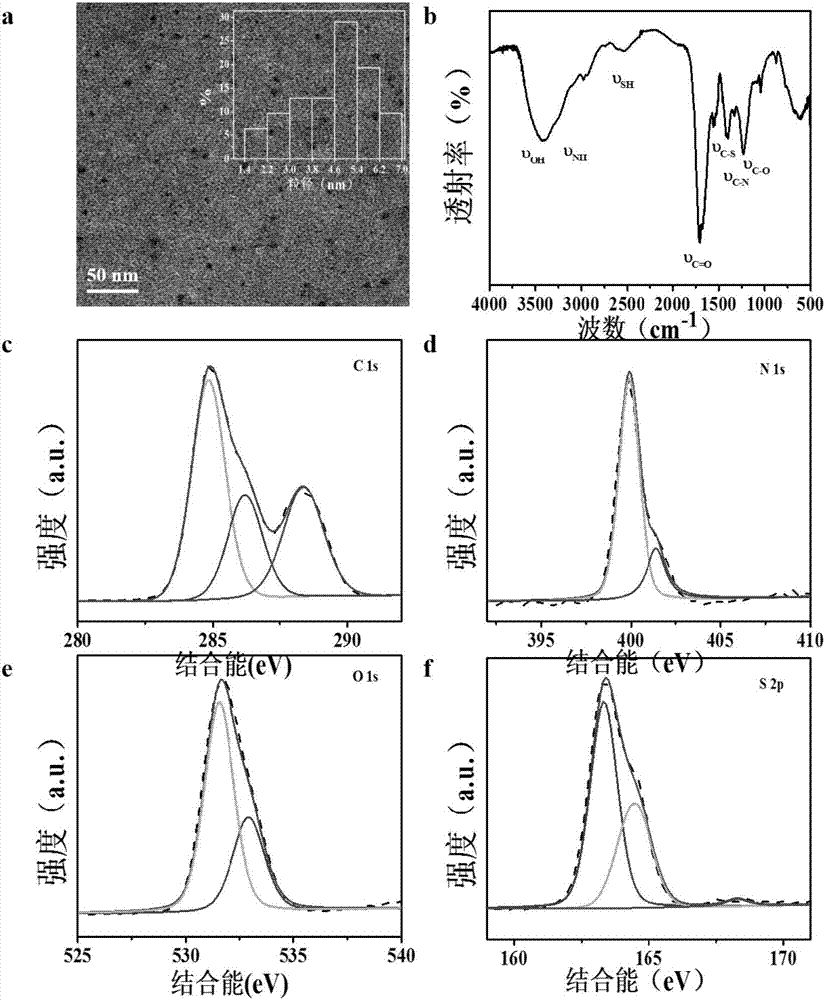

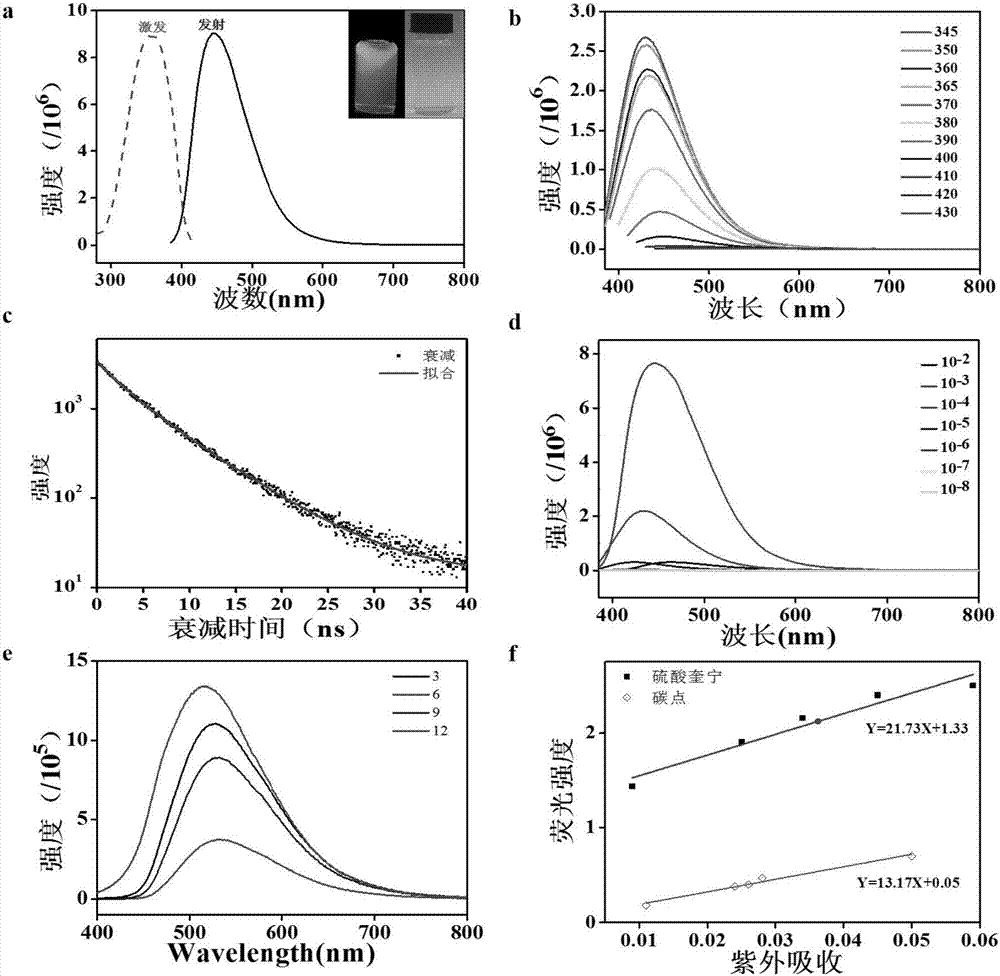

[0045] Example 1: Preparation of solid-state fluorescent carbon dots

[0046] Put 3.5g CA (Sinopharm Group), 5.1g GSH (Bailingwei), and 20mL ultrapure water in a 100mL polytetrafluoroethylene beaker, mix and stir at room temperature and ultrasonicate for 10min to make the solution uniform and stable. Put it into a microwave oven with adjustable power, dehydrate it with 750W microwave for 2 minutes, then continue heating and drying with 300W microwave for 2 minutes to obtain a light yellow sol, and obtain a solid after cooling to room temperature. The product is filtered, 13000r·min -1 Centrifuge for 15 minutes, and dialysis with 8kD dialysis bag for 2 days. Keep the solution in the dialysis bag and freeze-dry it. The obtained solid was pulverized and placed in a constant temperature and humidity chamber (25° C., 15% humidity) to prevent deliquescence.

[0047] The obtained carbon dots have solid-state blue fluorescence characteristics, and the particle size is uniform and st...

Embodiment 2

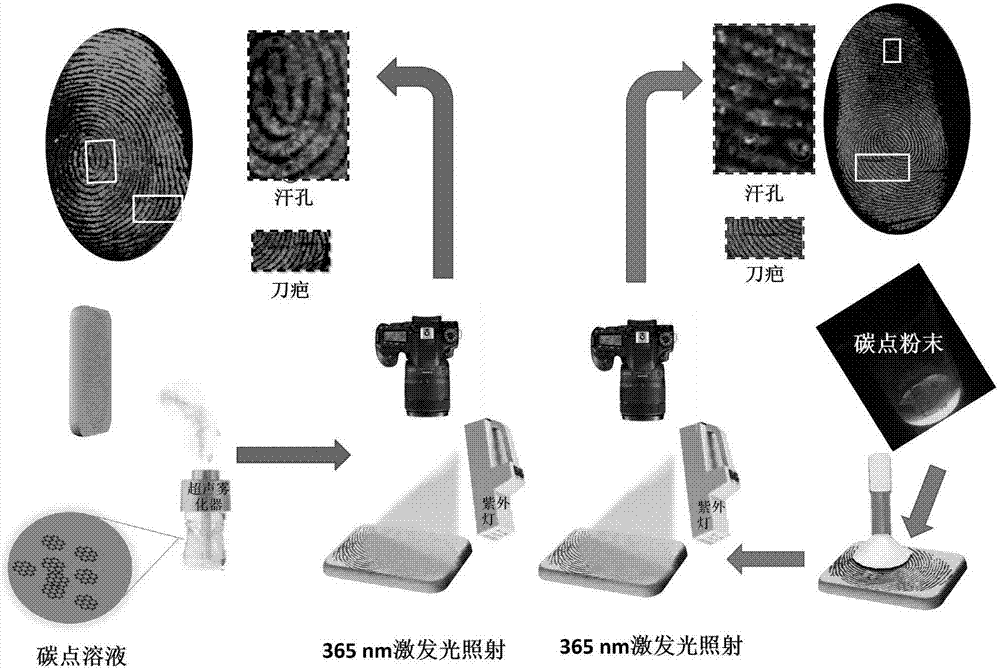

[0049] Embodiment 2: Application of liquid spray method to visualize latent fingerprints on aluminum foil

[0050] (1) Preparation of latent fingerprints: After washing and drying hands, lightly touch the bridge of the nose or forehead with fingertips, and then press the surface of the aluminum foil with moderate force to obtain latent fingerprints.

[0051] (2) Prepare 1mM SFCDs with ultrapure water, and adjust the pH of the solution to about 9 with 1M NaOH solution.

[0052] (3) Place the 1mM SFCDs solution in an ultrasonic nebulizer to atomize the solution. The atomized small droplet size is about 1-3μm. The aluminum foil object loaded with latent fingerprints is placed about 20cm away from the spray source and sprayed for 60s.

[0053] (4) Place the sprayed aluminum foil object under a UV lamp for irradiation, the excitation light source is 365nm, and obtain a fluorescent fingerprint image containing tertiary information with an ordinary digital camera (see image 3 shown...

Embodiment 3

[0057] Example 3: Application of powder method to visualize latent fingerprints on aluminum foil

[0058] (1) Preparation of latent fingerprints: After washing and drying hands, lightly touch the bridge of the nose or forehead with fingertips, and then press the surface of the aluminum foil with moderate force to obtain latent fingerprints.

[0059] (2) Dip the preserved solid powder with a fingerprint brush, brush lightly in the same direction, and finally shake off the excess powder with a fingerprint brush.

[0060] (3) Place the sprayed aluminum foil object under ultraviolet light for irradiation, the excitation light source is 365nm, and obtain a fluorescent fingerprint image containing tertiary information with an ordinary digital camera (see image 3 shown).

[0061] Change the object of above-mentioned step (1), obtain the fluorescent fingerprint image on the object being printing paper, plastics, glass, aluminum foil, pottery and stainless steel respectively, as Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com