Method for synthesizing dichloroether ether and 2-chloroethoxyethanol

A technology of chloroethoxyethanol and synthesis method, which is applied in chemical instruments and methods, ether preparation, ether separation/purification, etc., and can solve the problems of poor controllability of synthesis of 2-chloroethoxyethanol, difficult control of sulfuric acid, and flammability Explosive and other problems, to achieve the effect of safe and controllable synthesis, simple and controllable reaction, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

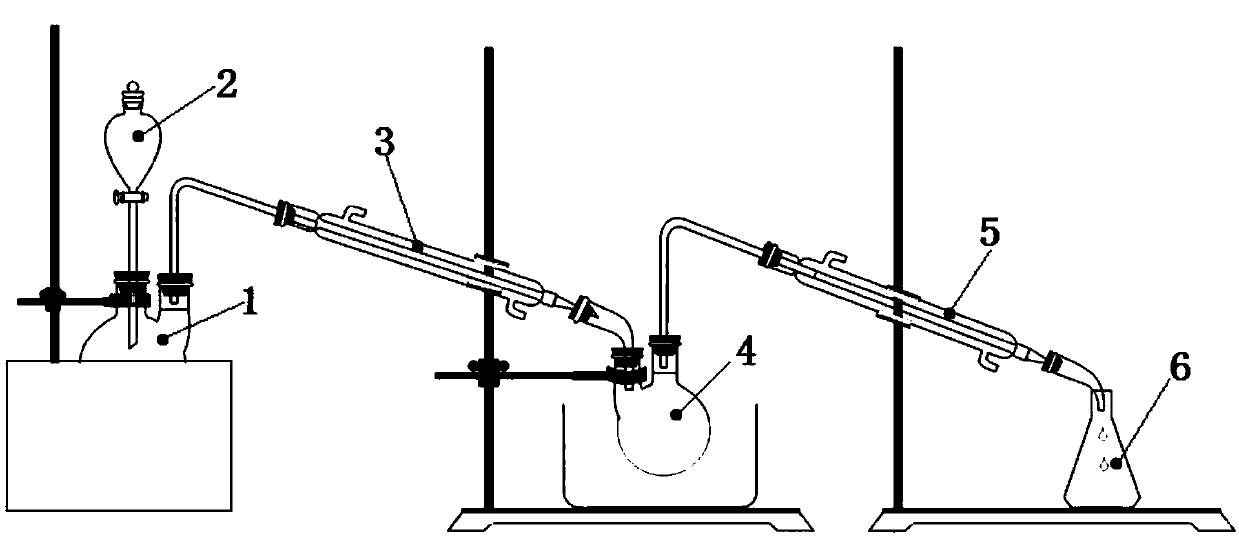

[0034] The embodiment of the present invention provides a synthetic method of dichloroethyl ether and 2-chloroethoxyethanol, the method comprising: adding diethylene glycol and a catalyst in a two-necked flask with a molar ratio of 0.8-1.5:0.3, and making the two-necked flask The two bottlenecks of flask 1 are respectively connected with separatory funnel and condenser tube;

[0035] Use a separatory funnel to drop the mixed acid into the double-necked flask, and react at 130°C-170°C. During the reaction, use a condenser to collect the condensate;

[0036] The condensate is distilled to obtain dichloroethyl ether;

[0037] The remaining liquid in the two-necked flask is suction filtered to obtain 2-chloroethoxyethanol;

[0038] The mixed acid includes: concentrated hydrochloric acid and concentrated sulfuric acid with a mass ratio of 25-35:1.

[0039] The method provided by the embodiment of the present invention can simultaneously generate dichloroethyl ether and 2-chloroet...

Embodiment 1

[0062] In this embodiment, the attached figure 1 Described synthesis device carries out the synthesis of dichloroethyl ether and 2-chloroethoxyethanol, and the steps are as follows:

[0063] Take 106g of diethylene glycol and 40.8g of zinc chloride and add them respectively to the first two-necked flask 1, and take 480ml of mixed acid and add them to the separatory funnel 2, and drop them into the first two-necked flask 1 at a rate of 20 drops / min. During this process, the reaction was carried out at 160° C. for 7 h under stirring conditions. The distilled liquid is condensed and recovered by the first condensing pipe 3 to obtain a light yellow transparent condensate. Wherein, the mixed acid is concentrated hydrochloric acid and concentrated sulfuric acid with a mass ratio of 30:1.

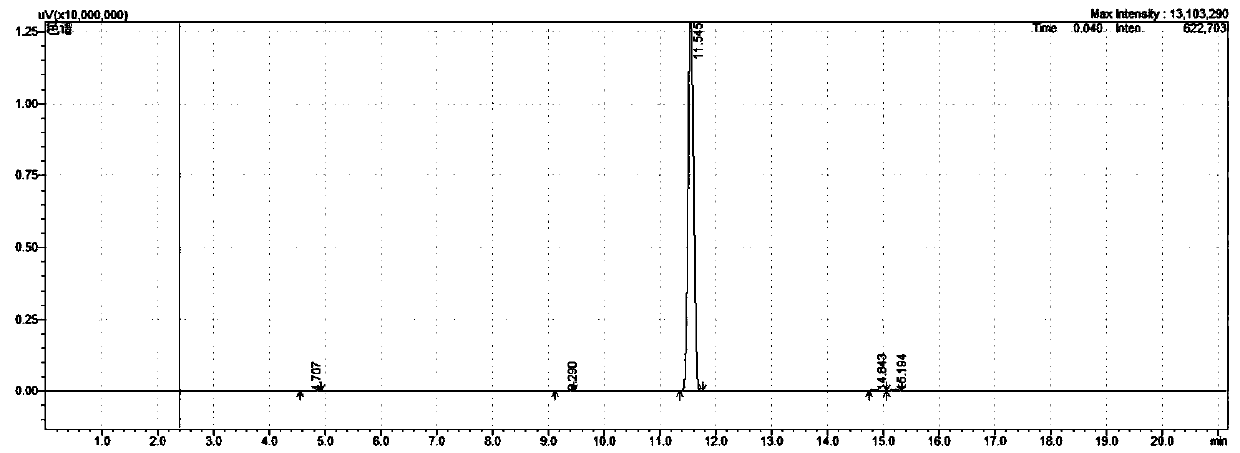

[0064] Get 1ml reaction liquid from the first two-necked flask 1, detect the content of 2-chloroethoxyethanol with gas chromatography, the measurement result shows: the selectivity of 2-chloroet...

Embodiment 2

[0067] In this embodiment, the attached figure 1 Described synthesis device carries out the synthesis of dichloroethyl ether and 2-chloroethoxyethanol, and the steps are as follows:

[0068] Take 106g of diethylene glycol and 40.8g of zinc chloride and add them respectively to the first two-necked flask 1, get 480ml of mixed acid and add them to the separatory funnel 2, and drop them into the first two-necked flask 1 at a rate of 15 drops / min. During this process, the reaction was carried out at 160° C. for 10 h under stirring conditions. The distilled liquid is condensed and recovered by the first condensing pipe 3 to obtain a light yellow transparent condensate. Wherein, the mixed acid is concentrated hydrochloric acid and concentrated sulfuric acid with a mass ratio of 29:1.

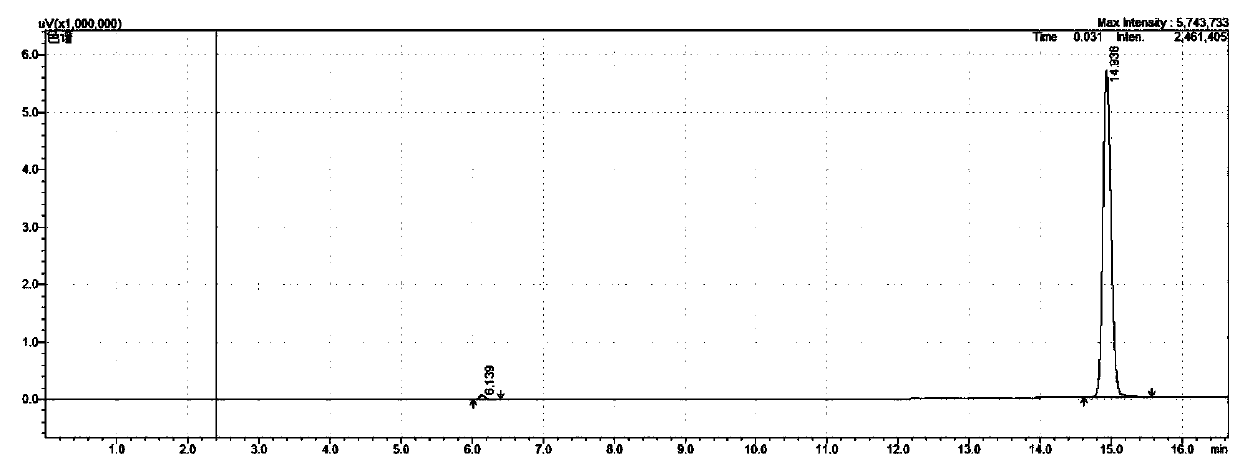

[0069] Get 1ml of reaction liquid from the first two-necked flask 1, detect the content of 2-chloroethoxyethanol with gas chromatography, the measurement result shows: the selectivity of 2-chloroeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com