Silicon-based phosphate and preparation method thereof

A technology of silicon-based phosphate ester and inorganic phosphate, which is applied in the direction of phosphorus organic compounds, can solve the problems of harming the body and the environment, corroding equipment, cumbersome preparation methods, etc., and meets the requirements of industrial production, low cost, and safe and easy-to-obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a method for preparing silicon-based phosphate, comprising the steps of:

[0045] Mixing disilazane compound, cyclic internal amine compound A and organic base for pre-reaction, then adding inorganic phosphate, and mixing reaction to prepare silicon-based phosphate;

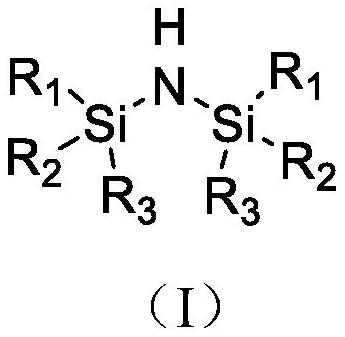

[0046] Disilazane compounds have a structure shown in the following formula (I):

[0047]

[0048] Among them, R 1 ~R 3 Each occurrence is independently selected from H, F, substituted or unsubstituted alkyl, substituted or unsubstituted alkoxy, substituted or unsubstituted unsaturated hydrocarbyl, or substituted or unsubstituted aromatic hydrocarbyl;

[0049] Cyclic internal amine compound A is selected from One of.

[0050] The present invention uses disilazane compounds as raw materials, which are cheap, but are easily hydrolyzed under neutral or acidic conditions. In the present invention, by adding an organic base to the reactant, on the one hand, the organic base can...

Embodiment 1

[0097] This embodiment provides a preparation method of silicon-based phosphate, the steps are as follows:

[0098] (1) Hydrogenate 2,5-dihydropyrrole (2.0mol), 1,3-divinyl-1,1,3,3-tetramethyldisilazane (1.5mol) and Sodium (0.3mol) was mixed, stirred and reacted for 3h, and the reaction temperature was kept at 20°C to continue the reaction;

[0099] (2) After almost no ammonia gas is produced, the temperature is raised, ammonia gas is evaporated at normal pressure and 60°C, and the temperature is kept constant, and ammonium dihydrogen phosphate (0.6mol) is added to react for 2.5 hours;

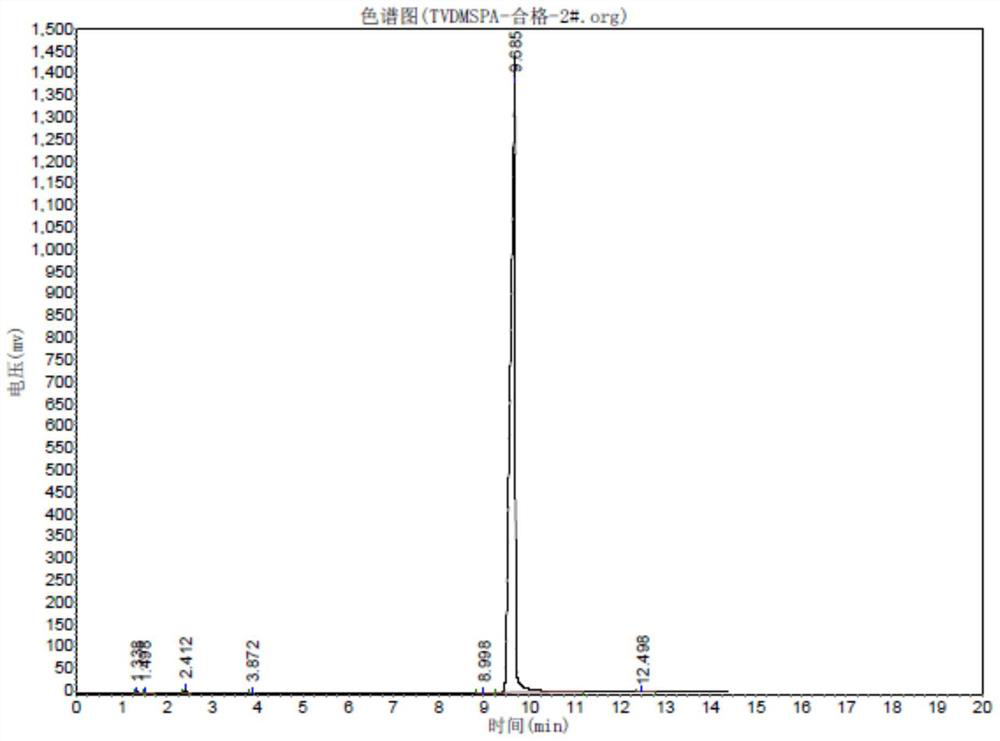

[0100] (3) After the reaction is over, distill under reduced pressure to obtain tris(vinyldimethylsilane) phosphate (0.49mol), with a yield of 81.7% and a purity of 99.65%. The results of GC chromatographic analysis are shown in figure 1 ,Table 1.

[0101] Table 1

[0102]

[0103]

Embodiment 2

[0105] This embodiment provides a preparation method of silicon-based phosphate, the steps are as follows:

[0106] (1) Under the condition of ice-water bath (0~4℃), mix 2,5-dihydropyrrole (2.0mol), 1,3-divinyl-1,1,3,3-tetramethyldisilazide Alkane (1.5mol) and sodium hydride (0.3mol) were mixed, stirred and reacted for 5h;

[0107] (2) After almost no ammonia gas is produced, the temperature is raised, and the ammonia gas is evaporated at normal pressure and 50°C, and the temperature is kept constant, and ammonium dihydrogen phosphate (0.6mol) is added to react for 3 hours;

[0108] (3) After the reaction was completed, tris(vinyldimethylsilane)phosphate (0.50 mol) was obtained by distillation under reduced pressure, with a yield of 83.3% and a purity of 99.71%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com