Rolling type powder-coating method for spiral fluorescent lamp tube and spiral lamp tube roller coating equipment

A fluorescent tube and rolling technology, which is applied in the application of luminescent paint, tube/lamp screen manufacturing, etc., can solve the problems that the area of the bottom of the tube cannot emit light, affect the appearance of the tube, reduce the light efficiency of the tube, etc., and achieve improvement Aesthetics, consumption saving, and the effect of solving the black shadow phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

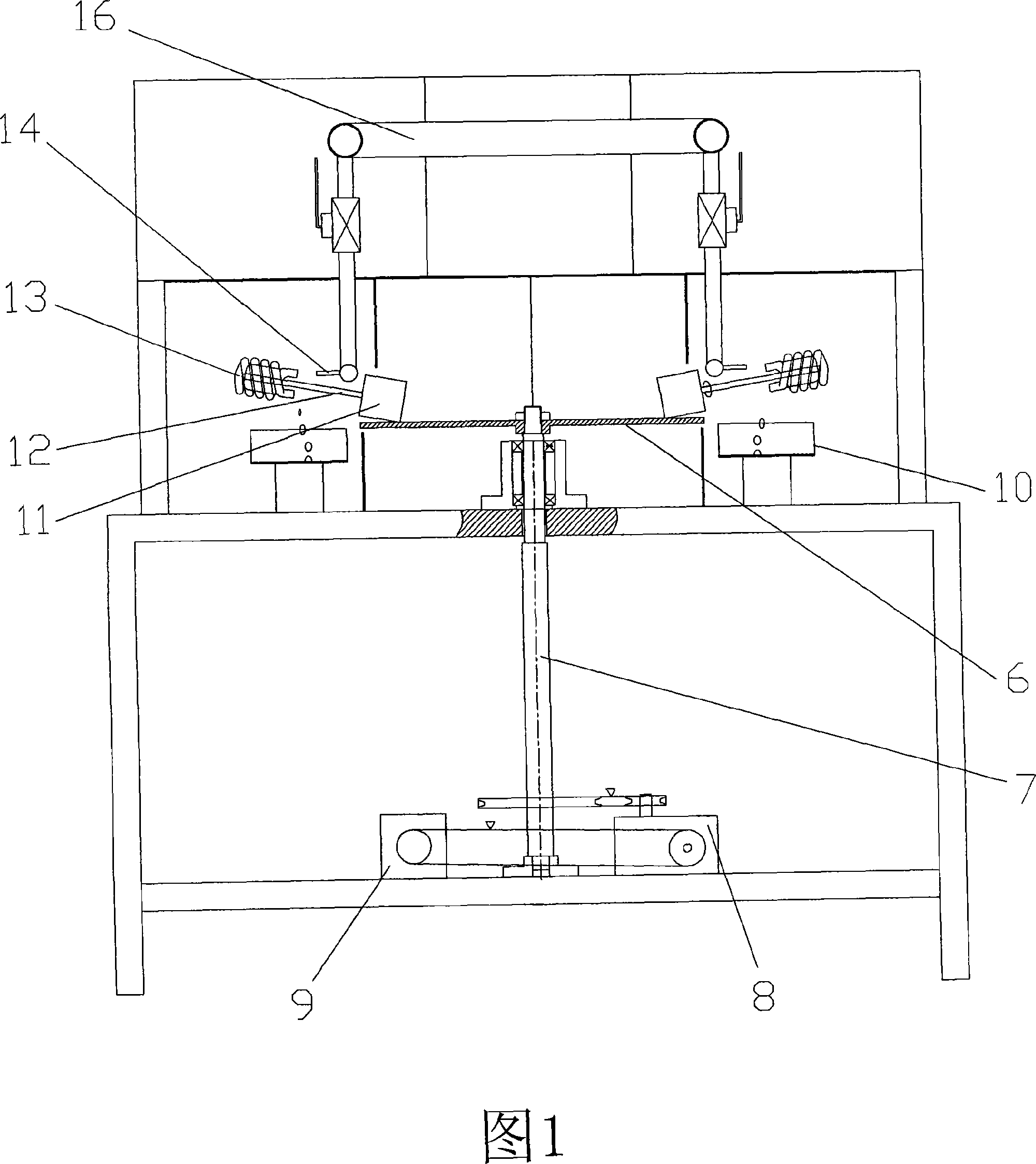

Image

Examples

Embodiment Construction

[0026] The inventor first studied the existing powder coating method, and found that the existing method of static drying of the spiral lamp tube cannot make the powder slurry at the bottom of each circle of the spiral lamp tube flow out during the coating process of the fluorescent powder slurry , so that the powder slurry is deposited in the lamp tube and adheres to the bottom of the tube wall, resulting in black shadow phenomenon.

[0027] Therefore, in order to effectively solve the black shadow phenomenon caused by the powder coating of the spiral lamp tube, the inventor has innovated the powder coating method of the spiral lamp tube, and invented the horizontal water-based roller coating method for powder coating; this powder coating method is carried out sequentially according to the following steps :

[0028] 1. Phosphor powder slurry injected into the lamp tube

[0029] Inject the well-proportioned phosphor powder slurry into the clean and dry spiral lamp tube after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com