Opticla glass

A kind of optical glass and glass technology, applied in the field of phosphate glass, can solve the problems of easy cracks, high liquidus temperature and defects in cooling glass, and achieve the effect of less temperature load, low liquidus temperature and good productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

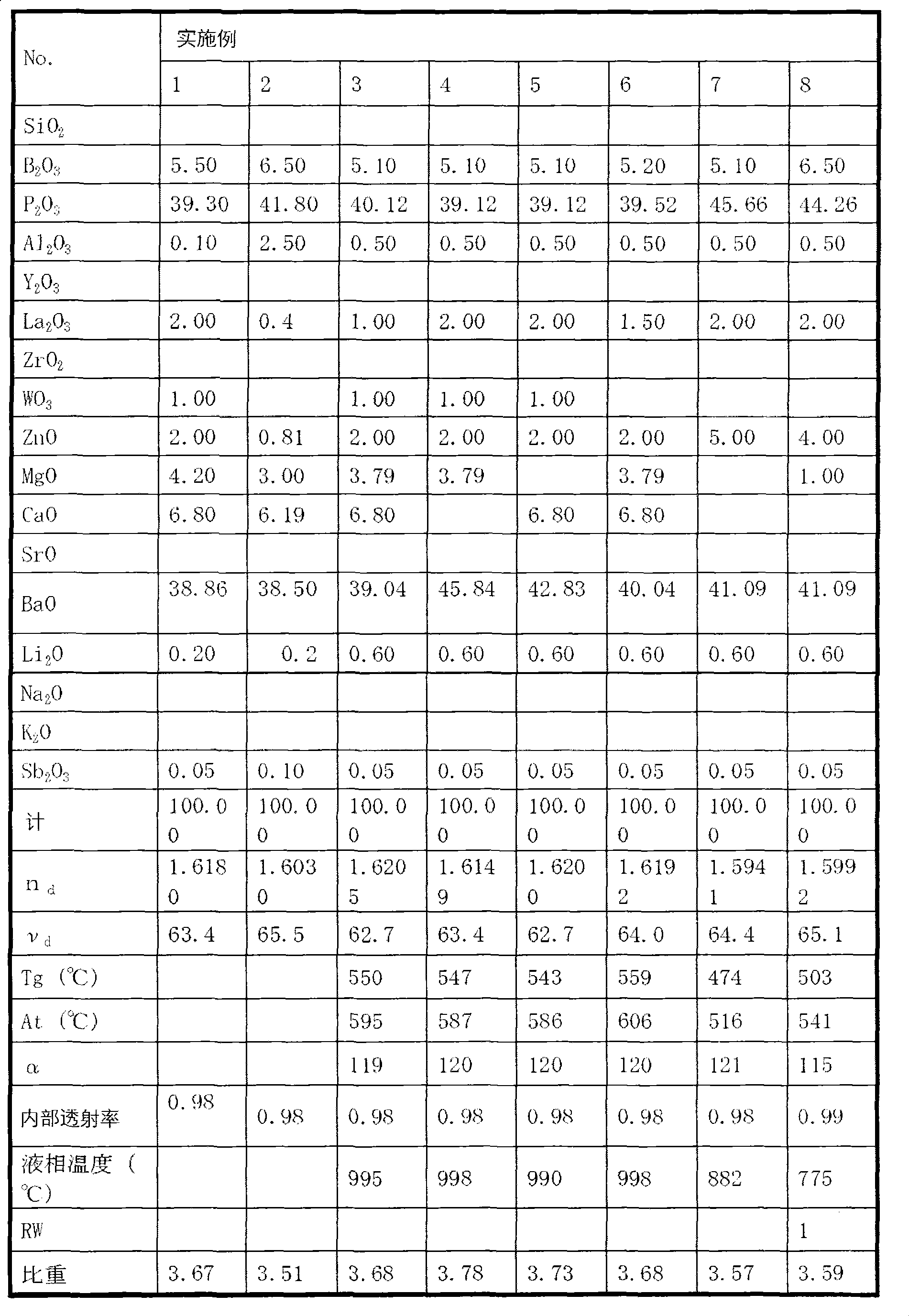

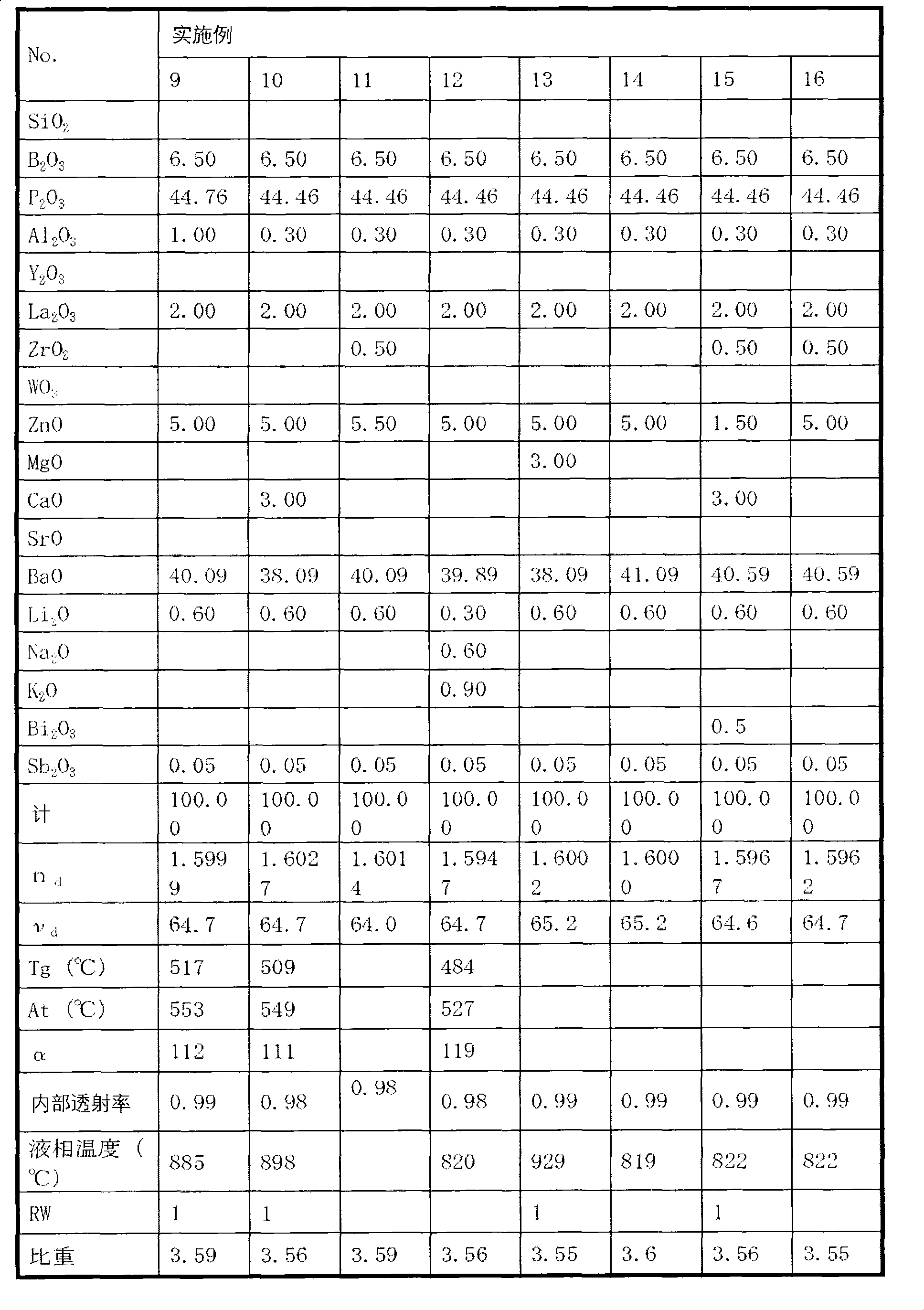

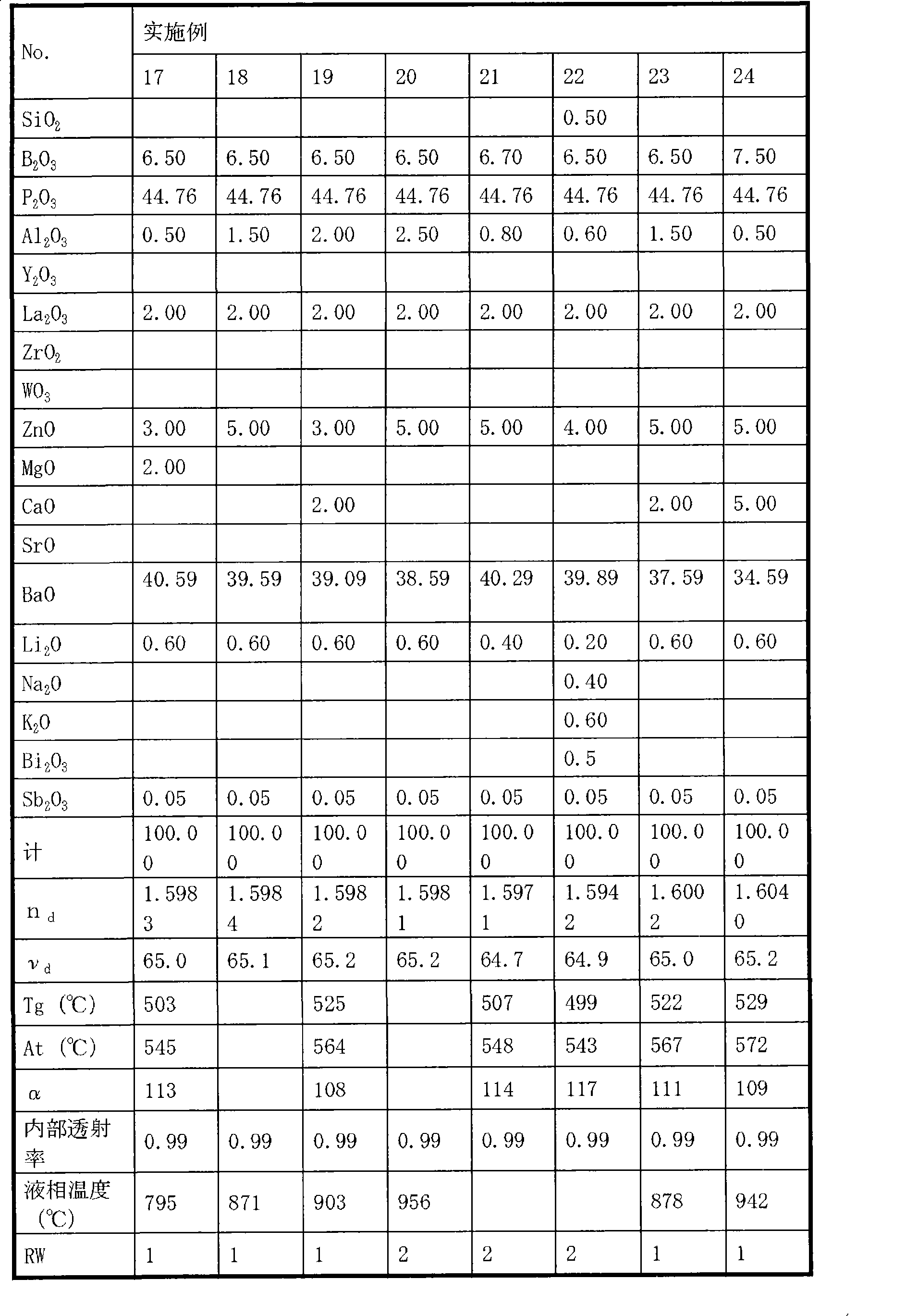

[0138] The compositions of Examples (No.1 to No.34) of the optical glass of the present invention and the composition of Example 2 described in JP 2004-262703 and the composition of Example 1 described in JP 2004-168593 are used as comparative examples (No.A, and No.B), optical constants (nd, vd), glass transition temperature (Tg), yield point At, average linear expansion coefficient α from 100 to 300°C, internal transmittance, liquidus temperature, The water resistance (RW) and specific gravity of the powder method are shown in Tables 2-6 and 8 and 9. Furthermore, the anomalous dispersion is shown in Table 7.

[0139] Furthermore, the glass of the Examples (No.1-No.34) of the present invention is obtained as follows: Common raw materials for optical glass such as oxides, carbonates, phosphates, and nitrates are weighed in a predetermined ratio, and after mixing, Put it into a platinum crucible, etc., according to the melting property of the glass composition, melt it at a te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com