Glass composition for sealing and sealed material

A glass composition and sealing material technology, which can be used in instruments, discharge lamps, electrical components, etc., and can solve problems such as insufficient time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

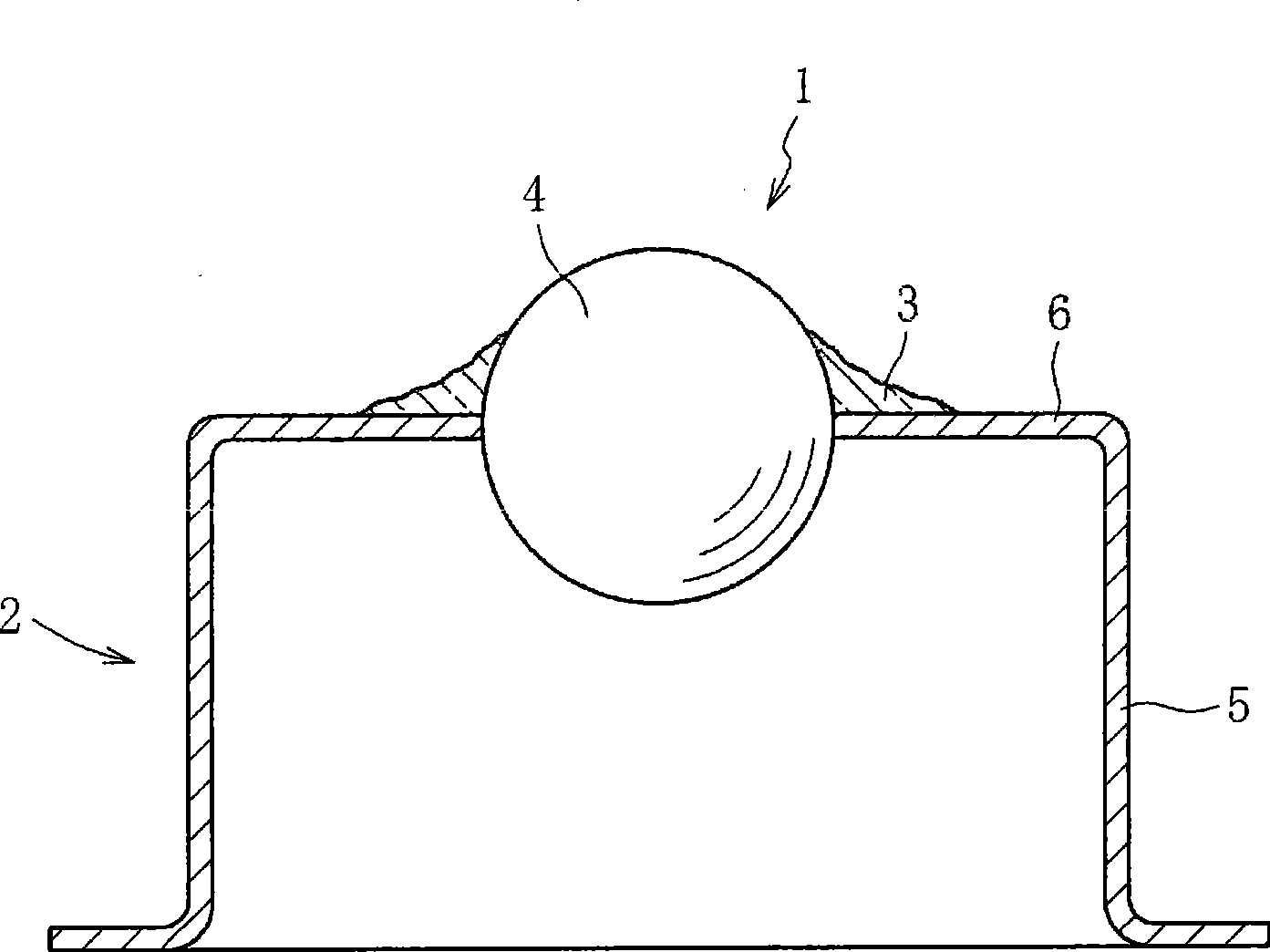

Image

Examples

Embodiment

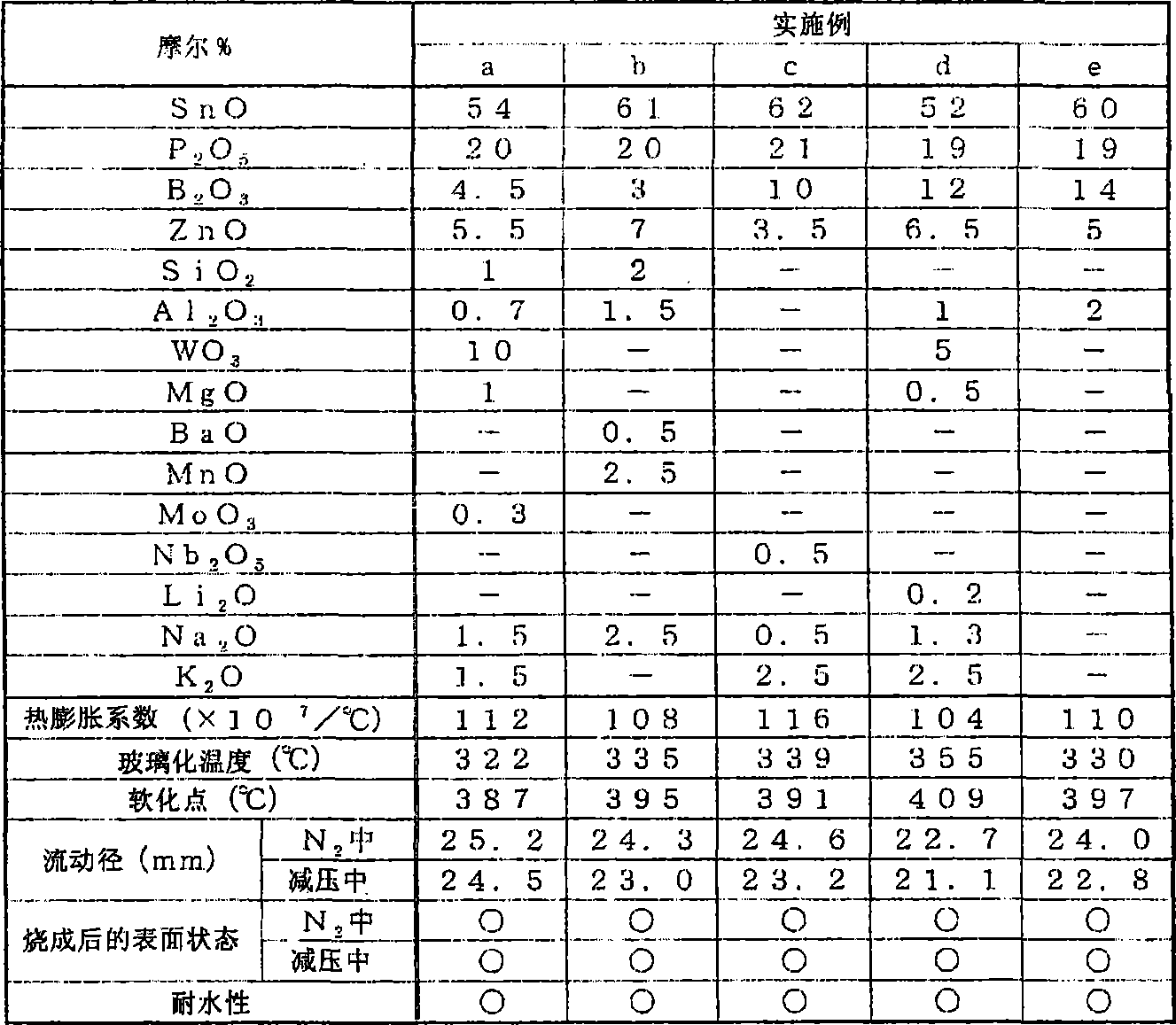

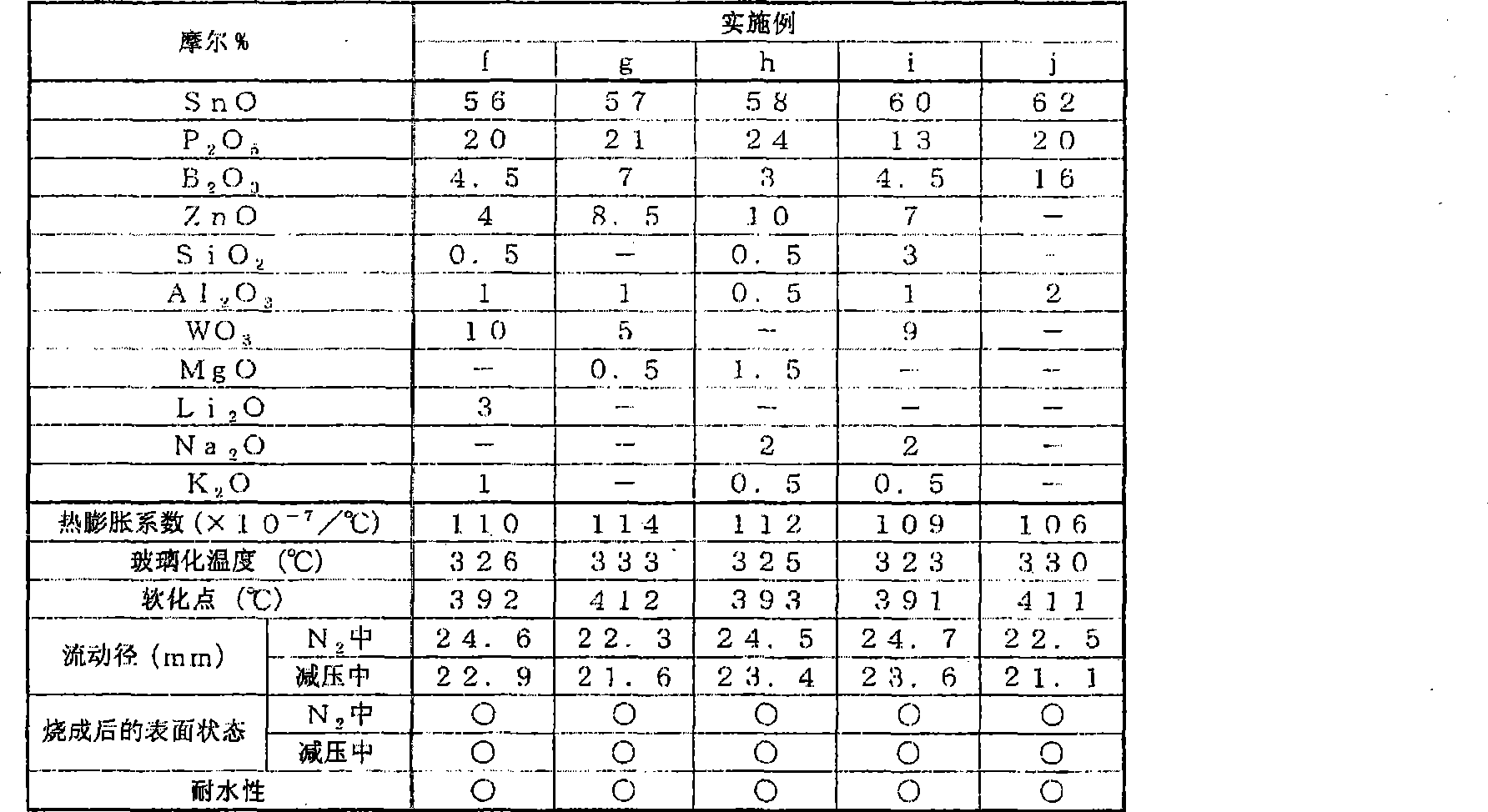

[0091] Hereinafter, the sealing glass composition and sealing material of the present invention will be described in detail based on examples.

[0092] Tables 1 to 3 show examples (samples a to n) of the sealing glass composition of the present invention, and Table 4 shows comparative examples (samples p, q).

[0093] [Table 1]

[0094]

[0095] [Table 2]

[0096]

[0097] [table 3]

[0098]

[0099] [Table 4]

[0100]

[0101] Each glass sample was prepared as follows. First, the masterbatch raw materials are prepared according to the glass compositions shown in Tables 1 to 4, and N 2 Gas based on N with a flow rate of 1L / min 2 The gas is bubbling into the molten glass, while using an alumina crucible, N in the electric furnace 2 Melt at 900°C in the atmosphere for 2 hours, then reduce the pressure to 50 Torr (6.65kPa) while keeping the inside of the electric furnace at 900°C, and maintain the reduced pressure for 1 hour to remove the gas components present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com