Precision press-molding preform, process for the production thereof, optical element and process for the production of the optical element

a technology of press-molding and preforms, which is applied in the direction of manufacturing tools, instruments, lenses, etc., can solve the problems of inability to produce high-quality production, inability to achieve excellent image reproduction, and reddish image obtained, etc., to achieve stable production of optical elements, excellent near infrared absorbing function, and excellent press-molding durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0120] Oxides, carbonates, sulfates, nitrates, phosphates, fluorides, hydroxides, etc., as raw materials for a glass were weighed in an amount of 250 to 300 g so as to obtain a glass composition having a predetermined amount ratio shown in Table 1, and these materials were fully mixed to obtain a formulated batch. The formulated batch was placed in a platinum crucible and melted in air with stirring at a temperature of 900 to 1,100° C. for 1 to 4 hours. After melted, a clarified and homogenized molten glass was cast into a 40×70×15 mm carbon mold and gradually cooled to a temperature around the glass transition temperature thereof, and immediately thereafter, the glass is placed in an annealing furnace and annealed around the glass transition temperature for about 1 hour to allow the glass to be cooled to room temperature. The thus-obtained optical glass was observed through an optical microscope to show no precipitation of a crystal.

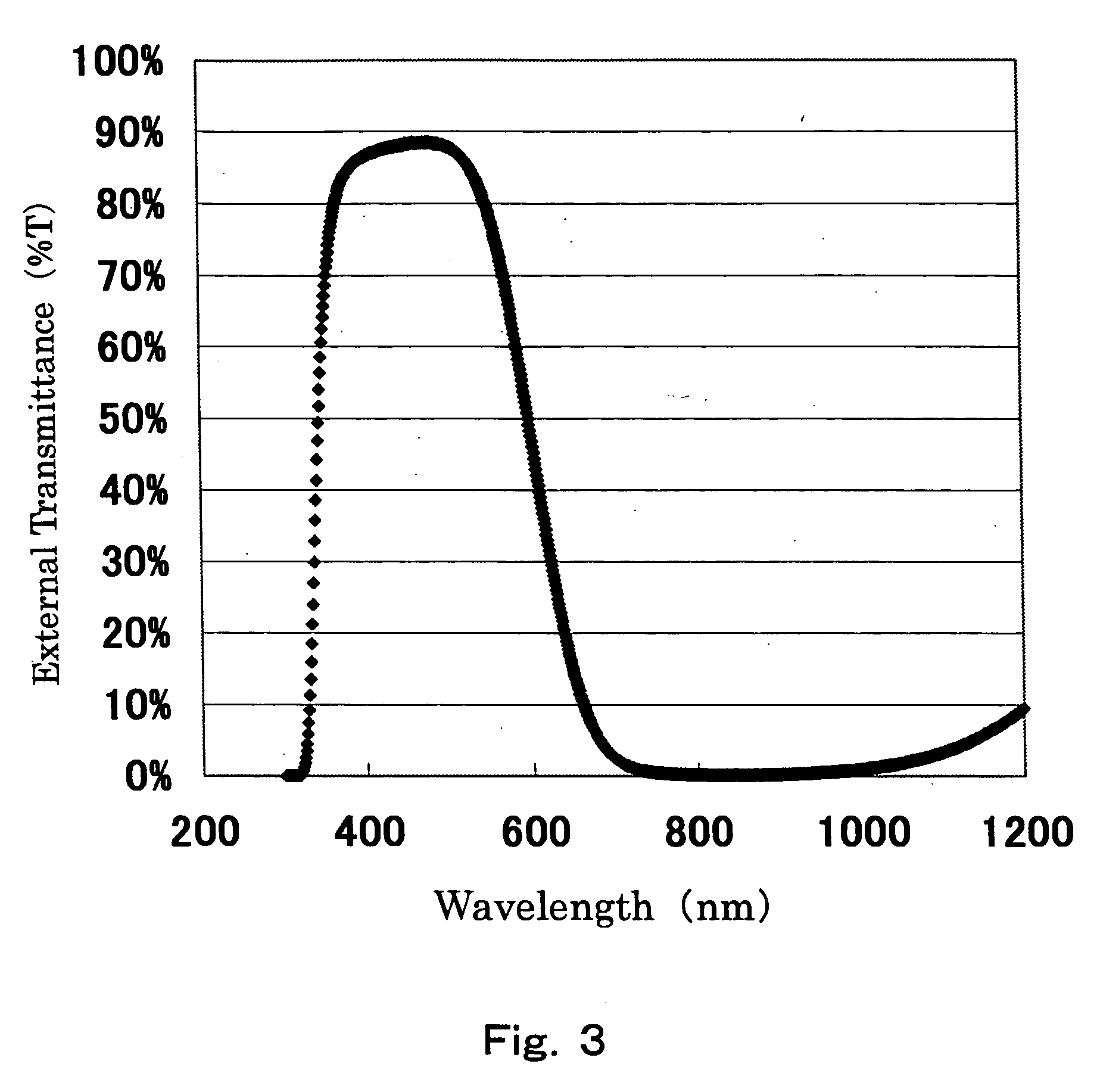

[0121] Table 2 shows external transmittances (T4...

example 2

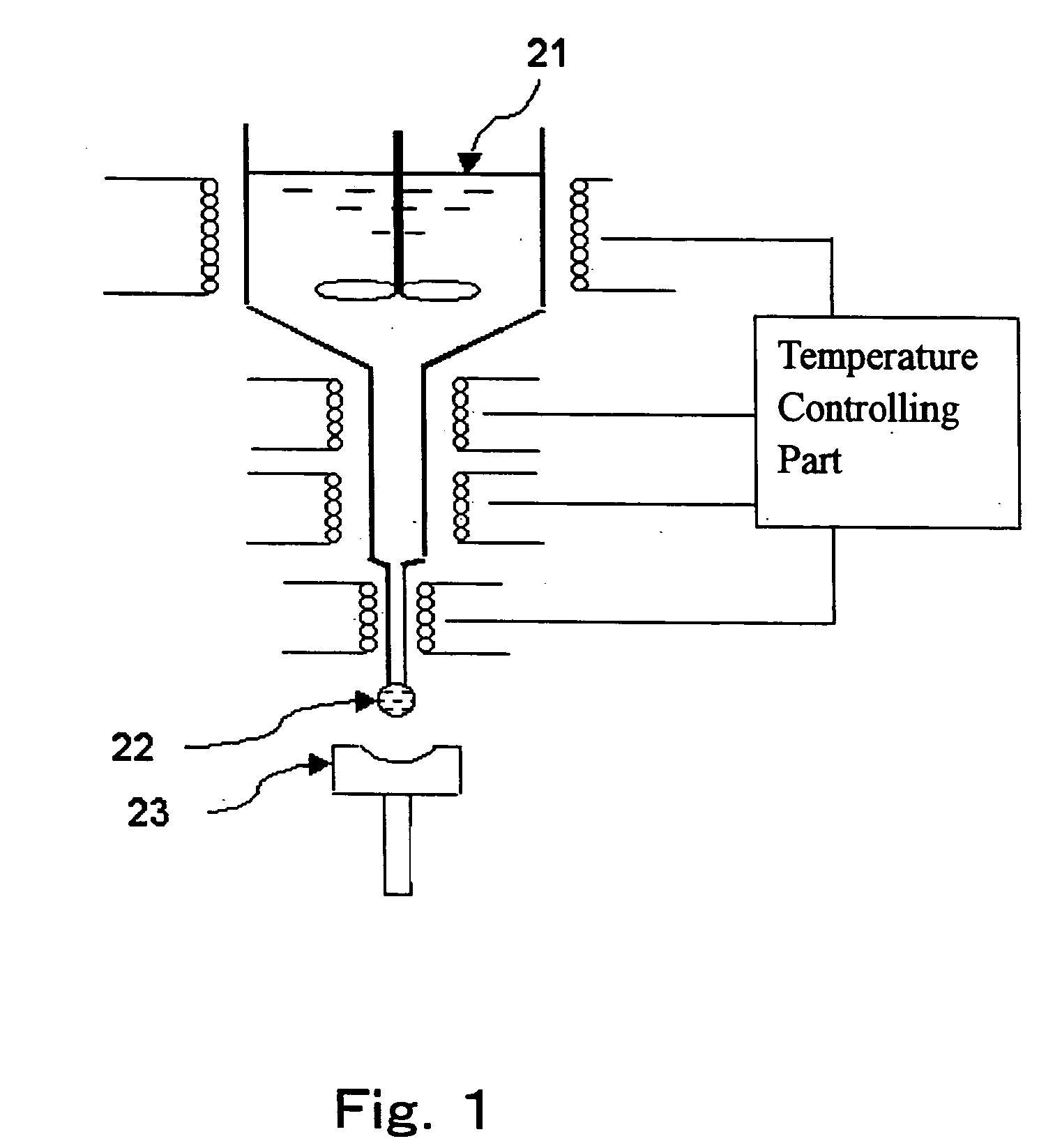

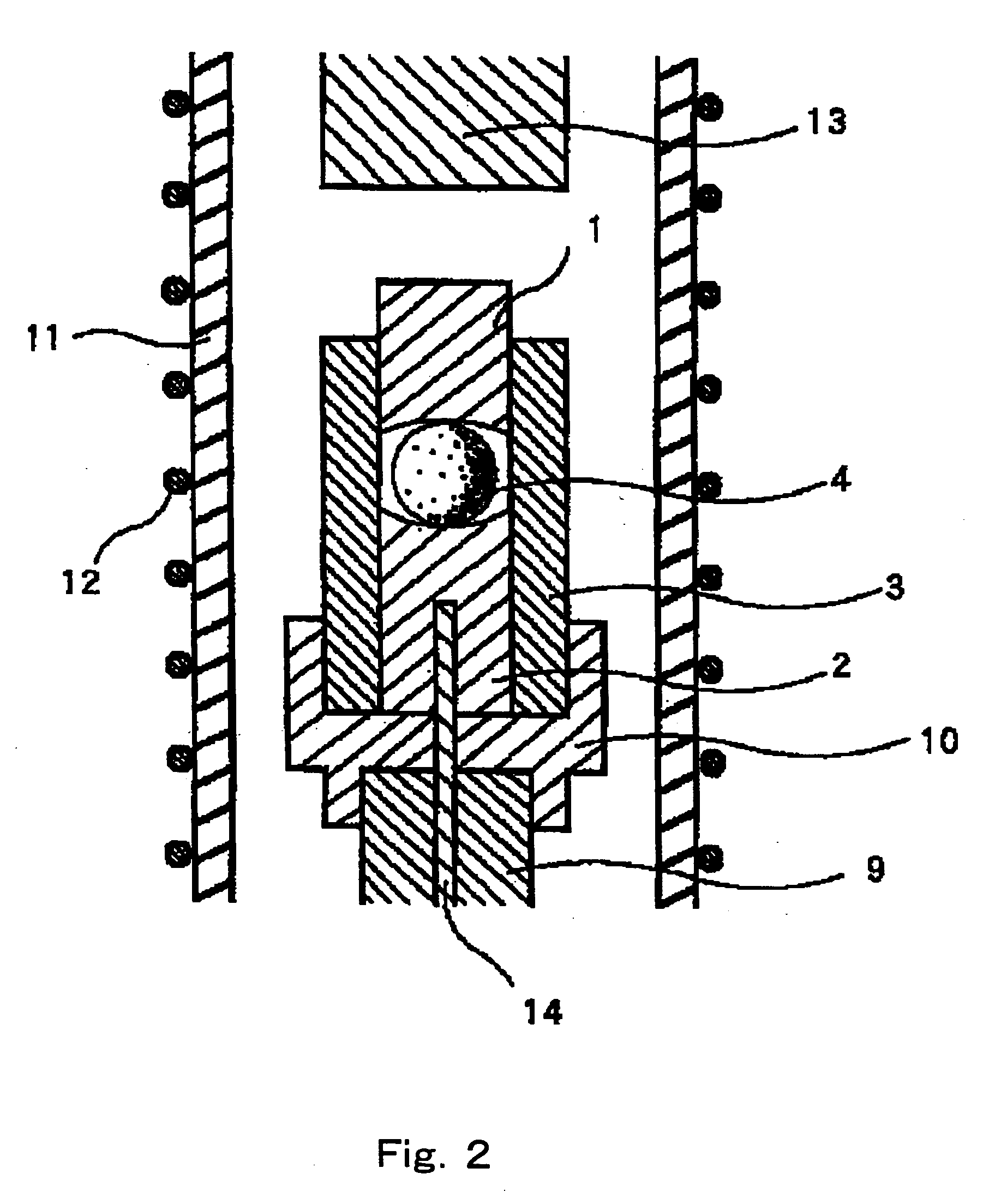

[0133]FIG. 2 shows a schematic cross-sectional view of a precision press-molding apparatus. A preform 4 that was obtained in the same manner as in Example 1 was placed between a lower mold member 2 and an upper mold member 1 of the precision press-molding apparatus shown in FIG. 2, and the atmosphere in a quartz tube 11 was replaced with a nitrogen atmosphere. A heater 12 was electrically powered to heat the quartz tube 11 internally. The temperature of the heater 12 was set such that the temperature inside a press mold was higher than the sag temperature of the glass by 20 to 60° C., and while the temperature was maintained, a pressing rod 13 was caused to move downward to press the upper mold member 1, so that the preform in the mold was precision press-molded. The molding pressure was adjusted to 8 MPa, and the molding time period was adjusted to 30 seconds. After the pressing, the molding pressure was decreased, and while the mold product was in a state where it was in contact i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com