Thermal cycling system

A thermal cycler and heat transfer coefficient technology, applied in the field of thermal cycle systems, can solve problems such as insufficient temperature change speed, expensive optical detection elements, and inability to achieve optimal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0214] Stainless Steel PCR Sample Tank

[0215] Stainless steel PCR sample wells have proven to be suitable vessels in which to perform the polymerase chain reaction. The vessel used for the initial testing was made of stainless steel tubing with a final outside diameter of 0.061 inches. The two inch long sample wells are closed at one end with a pressure fit stainless steel plug.

[0216] 20 μL of the same preparation for real-time polymerase chain reaction (using SYBR green intercalating dye as an indicator) was simultaneously placed in a commercially available glass PCR capillary tube and the metal sample holder described above. The reagents were then isolated from the outside air in each container by using 20 μL of mineral oil as an upper liquid layer. These containers were temperature cycled together for 40 cycles in a commercial real-time PCR machine, after which the contents of the metal sample wells were transferred to commercial glass PCR capillaries. Melting curve...

Embodiment 2

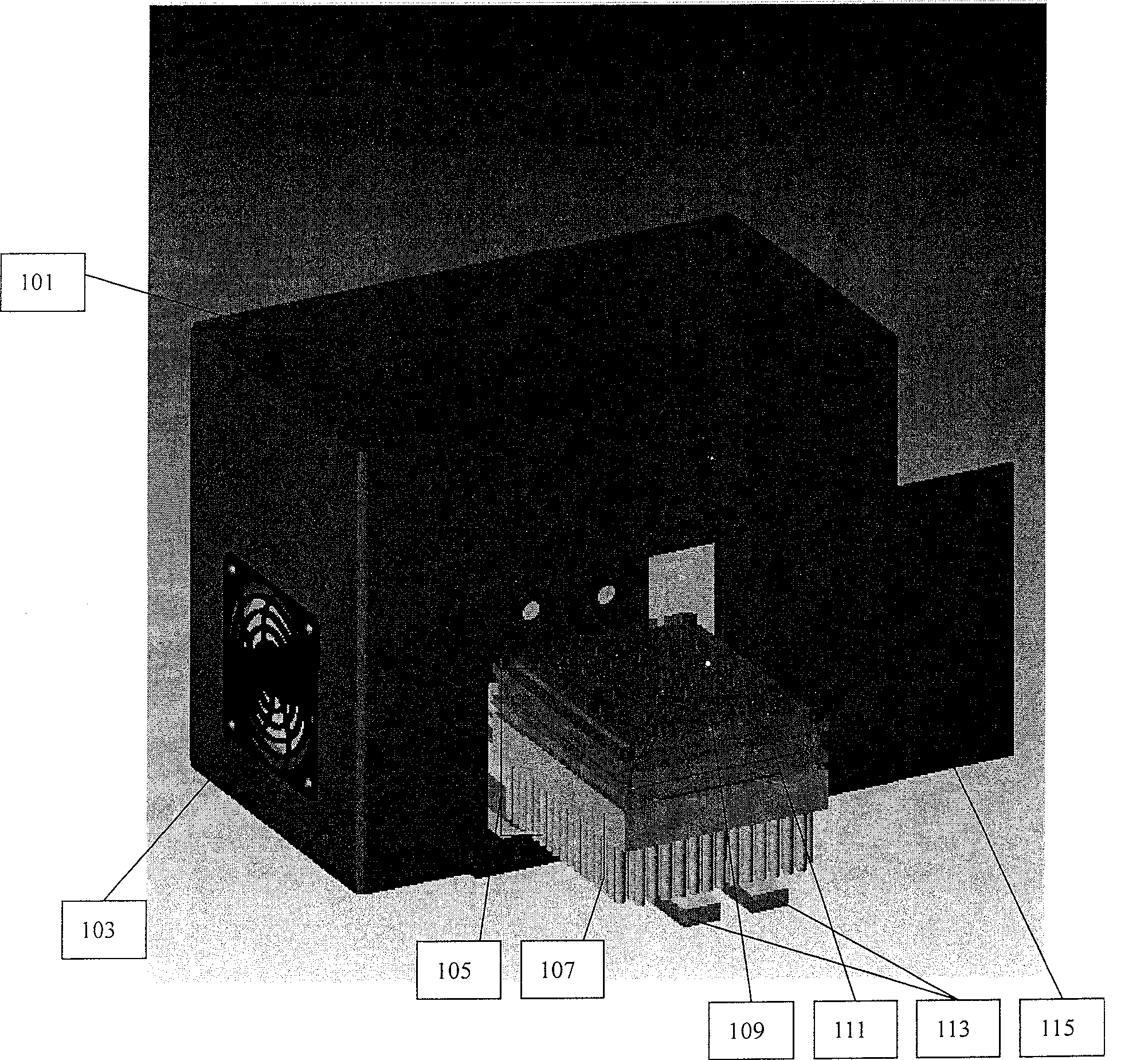

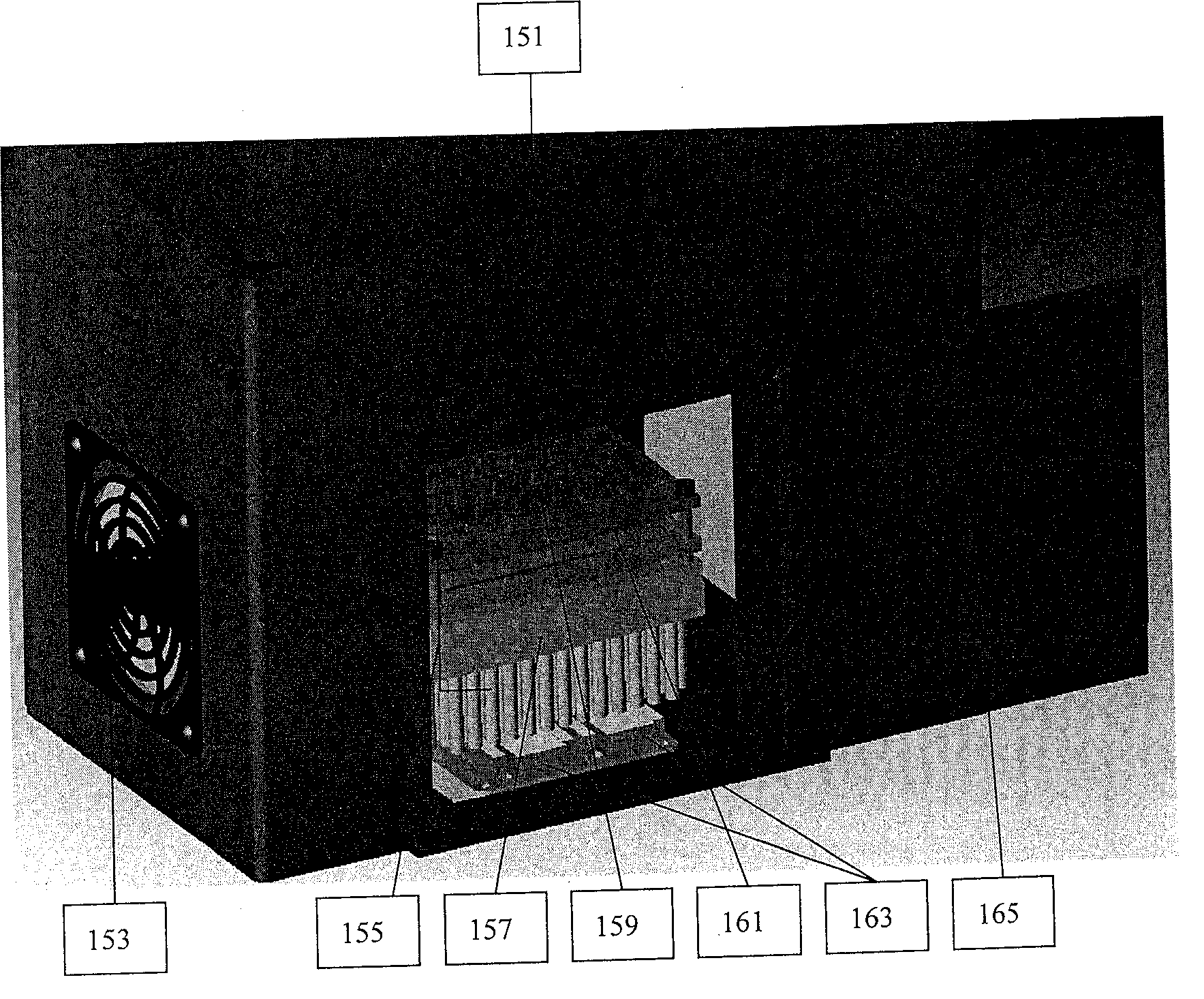

[0218] Real-time PCR

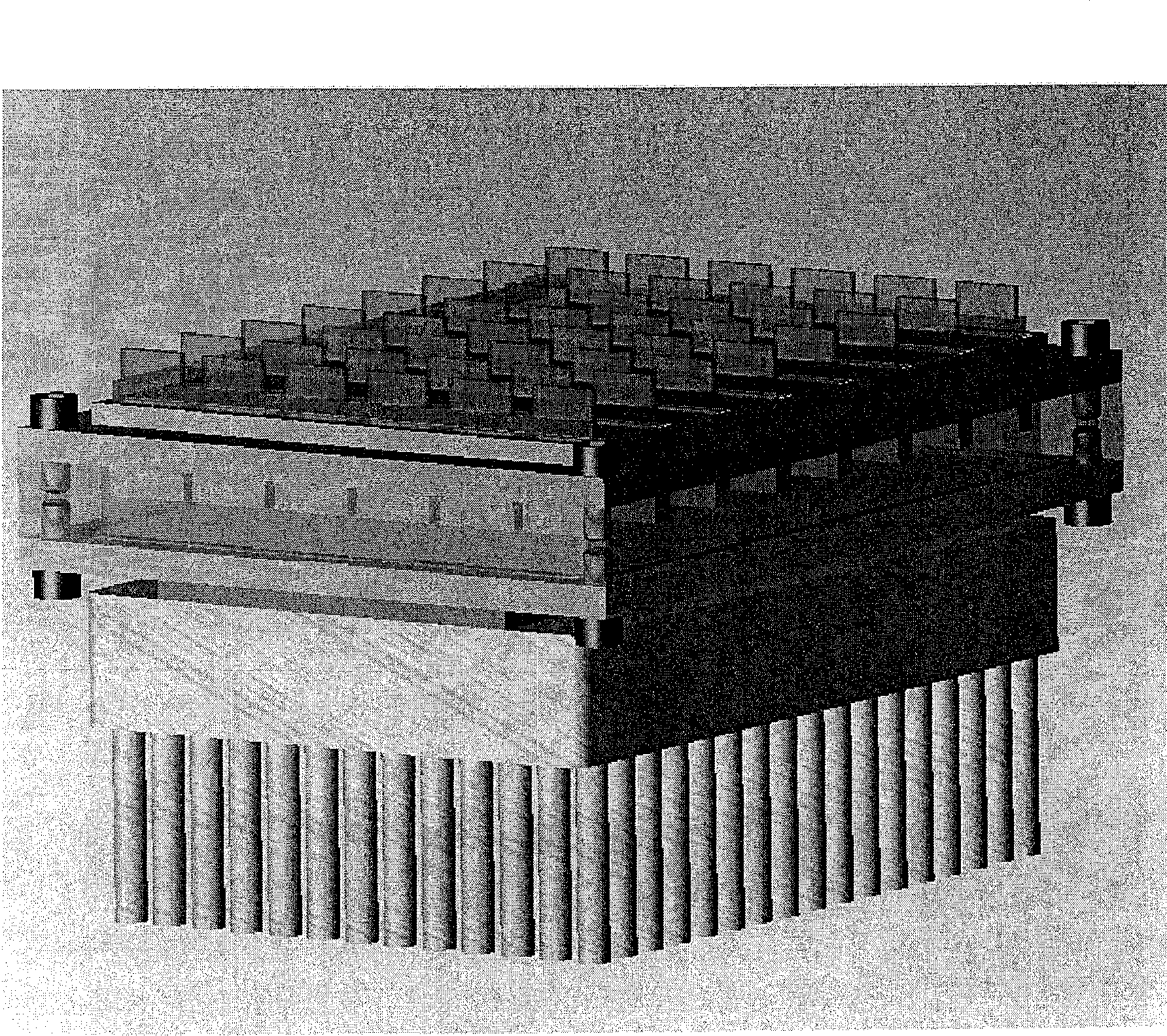

[0219] Liquid metal or thermal fluid heating blocks are ideal for real-time PCR reactions due to their fast ramp rates, thermal uniformity, and reflectivity.

[0220] Prepare the sample wells by adding the PCR reaction components to the wells and sealing the containers to prevent spillage or cross-contamination. Reaction components include buffer, target nucleic acid, appropriate primers and probes, nucleotides, polymerase, and optional additional components. In one embodiment, four fluorescent probes are included, each for detecting a different target sequence, and a particular reaction vessel may include any one or more of the fluorescent probes. Each probe advantageously responds to light having a different incident wavelength and emits light at a different wavelength.

[0221] A detection module is installed on the heating block. The detection module includes four detection channels. Each channel is optimized for one of the different fluorescent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com