Electroconductive pressure-sensitive adhesive tape

A conductive and adhesive tape technology, applied in the direction of conductive adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of adhesive tape lifting, difficult adhesion and conductivity, etc. To achieve the effect of quality improvement

Active Publication Date: 2010-08-18

NITTO DENKO CORP

View PDF2 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, with the thinning of the adhesive layer, it is difficult to achieve both adhesiveness and conductivity. In addition, when pasting a part with a height difference, the adhesive layer cannot completely absorb the height difference, and the adhesive tape "lifts" and other new problems, the status quo requires further improvement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

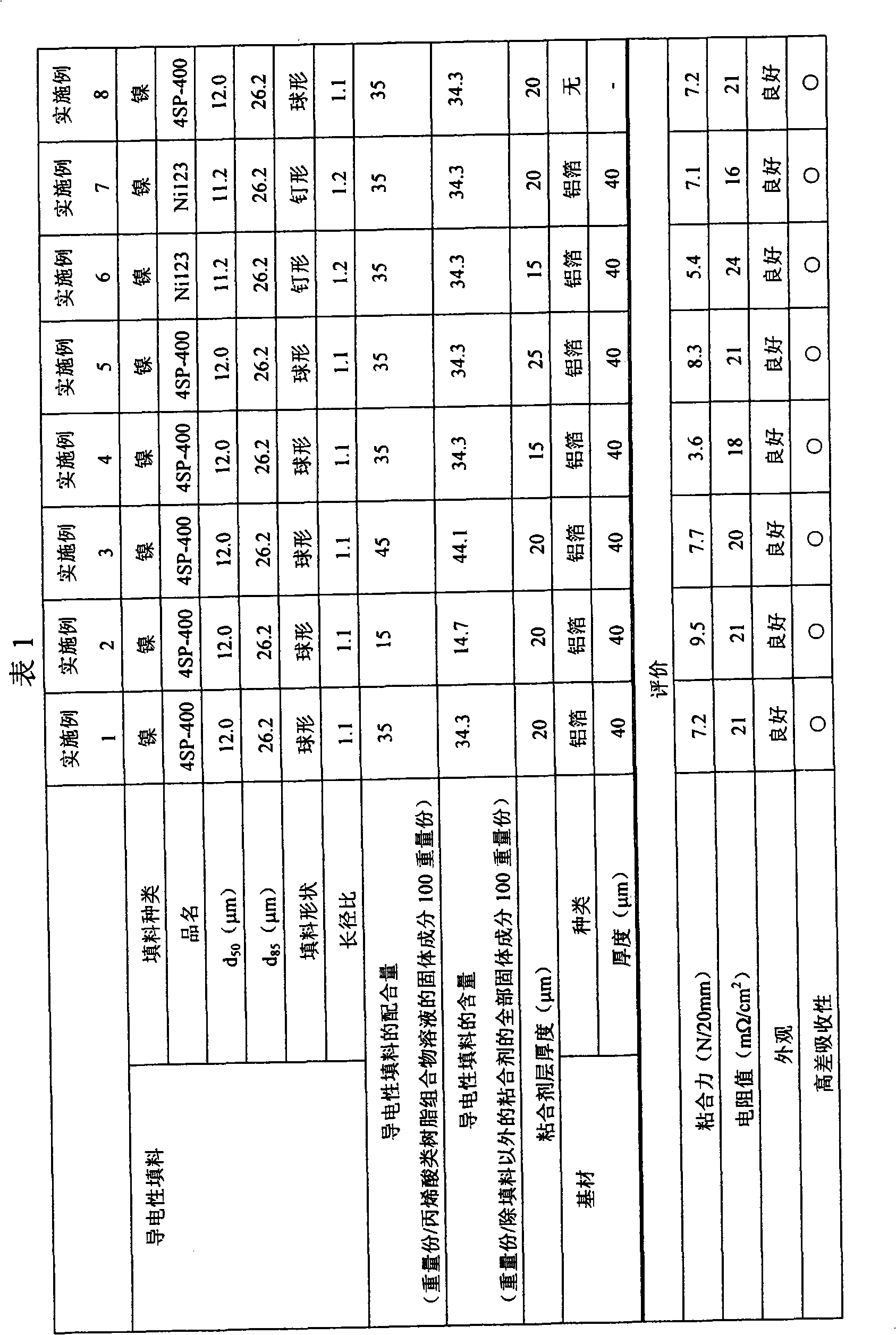

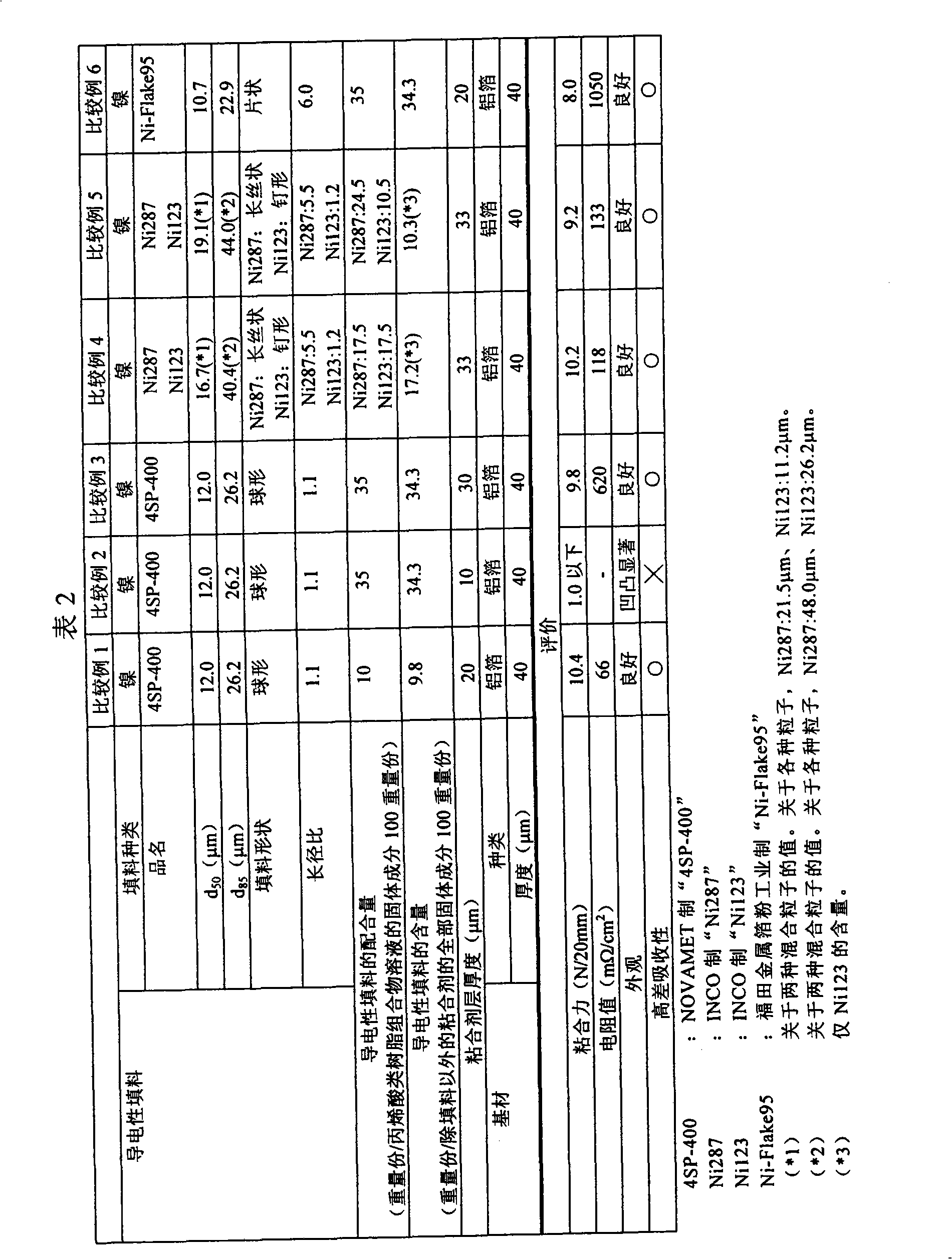

Embodiment 1

Embodiment 2、3

Embodiment 4、5

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Login to View More

Abstract

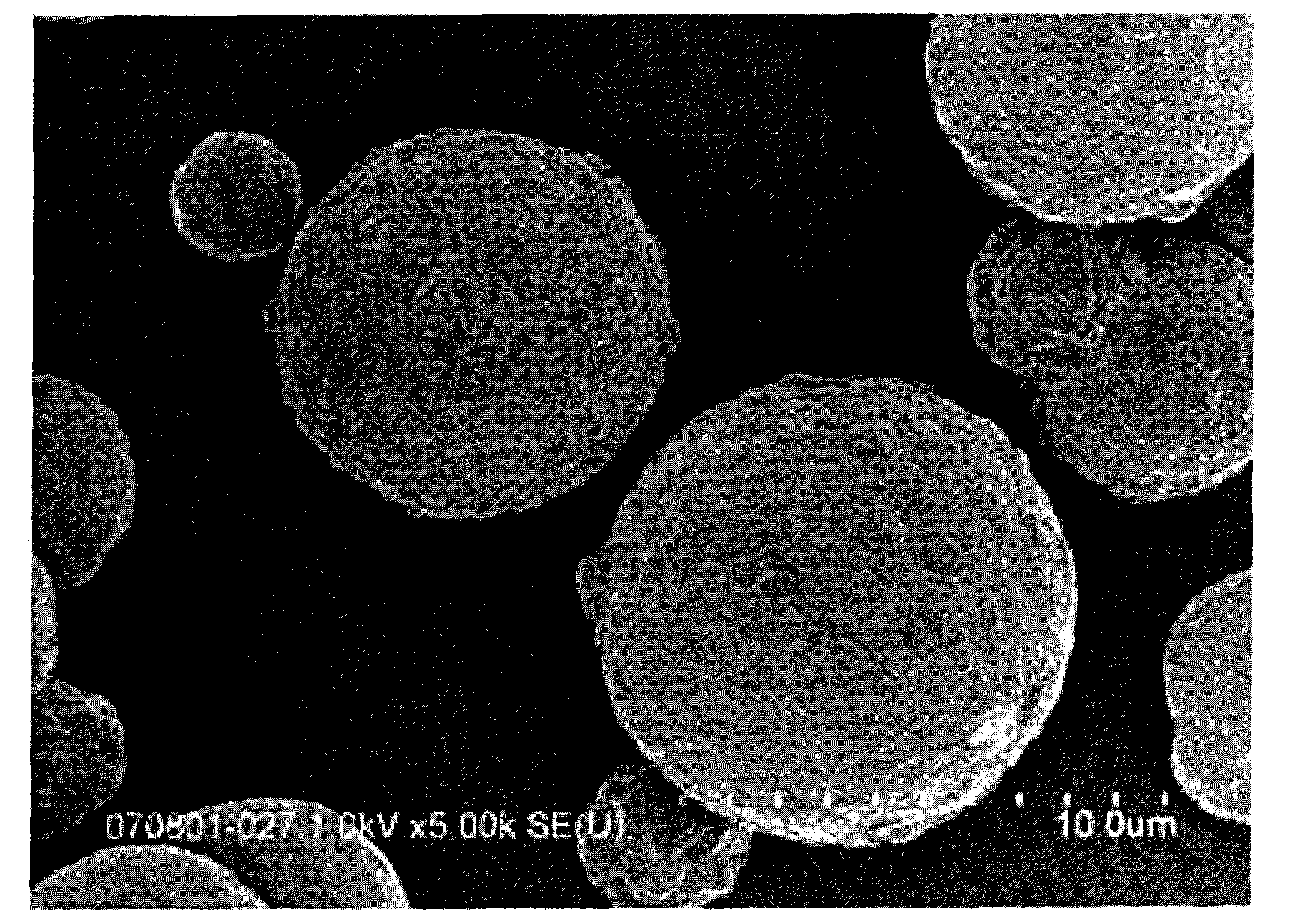

This invention provides an electroconductive pressure-sensitive adhesive tape comprising a pressure-sensitive adhesive layer having a thickness of 10 to 30 [mu]m. The pressure-sensitive adhesive layer is formed of a pressure-sensitive adhesive containing spherical and / or spike-like electroconductive fillers having an aspect ratio of 1.0 to 1.5. The amount of the electroconductive fillers is 14 to45 parts by weight based on 100 parts by weight of the total solid content of the pressure-sensitive adhesive excluding the filler. Not less than 90% by weight of all the fillers in the pressure-sensitive adhesive is accounted for by the electroconductive filler. The pressure-sensitive adhesive tape is characterized in that the particle diameter of the electoconductive filler (d50, d85) and the thickness of the pressure-sensitive adhesive layer satisfy a relationship of d85 > thickness of pressure-sensitive adhesive layer > d50. The electroconductive pressure-sensitive adhesive tape, even when the thickness of the pressure-sensitive adhesive layer is reduced, possesses excellent pressure-sensitive adhesive properties and electroconductive properties. Further, the electroconductive pressure-sensitive adhesive tape, even when applied to a step difference part, has a step difference absorbing property high enough to avoid 'lifting' from an adherend. Accordingly, the electroconductive pressure-sensitive adhesive tape is useful, for example, for the production of electric and electronic apparatuses and the like.

Description

technical field The present invention relates to a conductive adhesive tape. Background technique Conventionally, conductive pressure-sensitive adhesive tapes (including conductive pressure-sensitive adhesive sheets) have been used in applications such as electromagnetic wave shielding of electric equipment, electronic equipment, and cables, and grounding for antistatic purposes. As such a conductive adhesive tape, there is known an adhesive tape in which an adhesive layer is provided on a conductive substrate such as metal foil, and the adhesive layer is formed by dispersing a conductive filler such as nickel powder to enhance adhesiveness. The conductive adhesive obtained from the material is formed (refer to Patent Documents 1 and 2). In recent years, along with miniaturization and thinning of electric equipment and electronic equipment, thinning of conductive adhesive tapes used therein is also required. However, with the thinning of the adhesive layer, it is difficul...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J7/02C09J9/02C09J11/04C09J133/00C09J201/00H01B1/22H05F3/02H05K9/00C09J7/28

CPCC09J7/0292C08K3/0066C08K7/00H01B1/22C09J2201/606C09J133/06C09J7/0217C09J2433/00C09J2205/102C08K3/08C08K2201/016C08K3/017C09J7/385C09J7/28Y10T428/28Y10T428/25C09J2301/408C09J2301/302

Inventor 中山纯一岸冈宏昭

Owner NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com