Fiber reinforced type PP (polypropylene) material and preparation method thereof

A fiber-reinforced, glass fiber technology, applied in the field of fiber-reinforced PP materials and their preparation, can solve the problems of mechanical properties and hidden dangers of use, unbalanced shrinkage, and deterioration of material mechanical properties, and achieves high-efficiency ultraviolet shielding. ability, improve the interface bonding strength, improve the effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A preparation method of fiber-reinforced PP material, comprising the steps of:

[0046] The first step is to weigh each raw material according to the parts by weight, and put the polypropylene and glass fiber into an 80°C blast drying oven to dry until the moisture content is less than 3%;

[0047] The second step is to mix the dried polypropylene, glass fiber and other raw materials evenly, and then extrude and granulate through twin-screw to obtain plastic granules; wherein, the extrusion temperature is 220-230°C, the feed rate is 40kg / h, and the screw Speed 350r / min;

[0048] The third step is to heat the plastic particles to a molten state, and control the temperature to 250-255°C, and preheat the mold to 40-50°C at the same time, inject the molten material into the preheated mold, hold the pressure for molding, and hold the pressure time 10s, the PP material is obtained;

[0049] During the molding process, the melting temperature is controlled at 250-255°C. Wh...

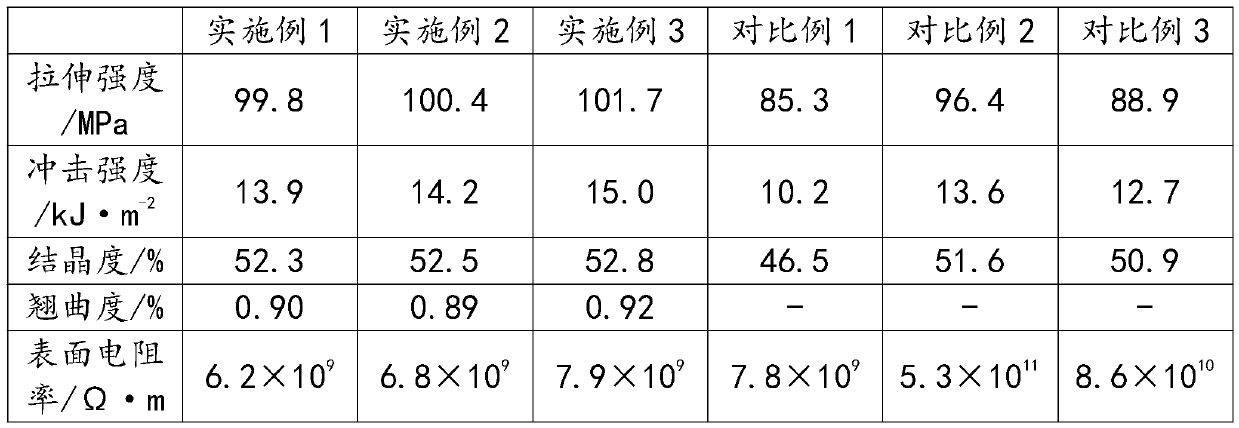

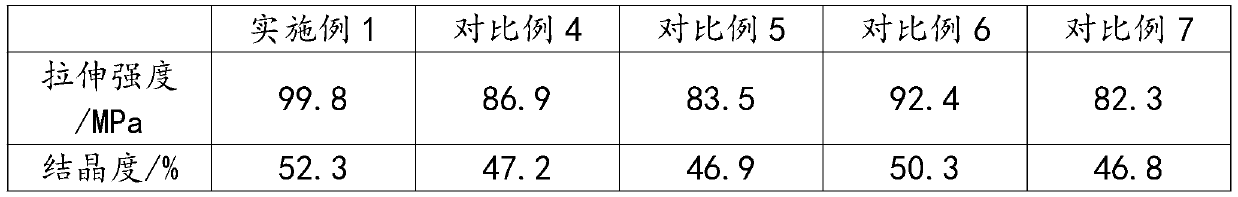

Embodiment 1

[0053] A fiber-reinforced PP material, made of the following raw materials in parts by weight: 65 parts of polypropylene, 26 parts of glass fiber, 4 parts of elastomer metallocene polyethylene, 0.8 parts of modified nano-titanium dioxide, 8 parts of modified conductive carbon black, 6 parts of compatibilizer, 0.5 part of plastic processing aid;

[0054] The PP material is made by the following steps:

[0055] The first step is to weigh each raw material according to the parts by weight, and put the polypropylene and glass fiber into an 80°C blast drying oven to dry until the moisture content is less than 3%;

[0056] The second step is to mix the dried polypropylene, glass fiber and other raw materials evenly, and then granulate through twin-screw extrusion to obtain plastic granules; wherein, the extrusion temperature is 220°C, the feeding amount is 40kg / h, and the screw speed is 350r / min;

[0057] The third step is to heat the plastic particles to a molten state, and cont...

Embodiment 2

[0059] A fiber-reinforced PP material, made of the following raw materials in parts by weight: 70 parts of polypropylene, 29 parts of glass fiber, 4.5 parts of elastomer metallocene polyethylene, 0.9 part of modified nano titanium dioxide, 9 parts of modified conductive carbon black, 6.5 parts of compatibilizer, 0.6 parts of plastic processing aid;

[0060] The PP material is made by the following steps:

[0061] The first step is to weigh each raw material according to the parts by weight, and put the polypropylene and glass fiber into an 80°C blast drying oven to dry until the moisture content is less than 3%;

[0062] The second step is to mix the dried polypropylene, glass fiber and other raw materials evenly, and then extrude and granulate through twin-screws to obtain plastic granules; wherein, the extrusion temperature is 225°C, the feed rate is 40kg / h, and the screw speed is 350r / min;

[0063] The third step is to heat the plastic particles to a molten state, and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com